High-linear-energy submerged-arc welding method for bridge steel with yield strength higher than or equal to 500MPa

A technology with yield strength and large input energy, applied in the field of large input energy submerged arc welding, can solve the problems of construction environment, manufacturing cost and manufacturing cycle, low production efficiency, low strength level, etc., and achieve high impact toughness reserve and safety margin The effect of high degree, easy operation and excellent crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Substrate for bridges: the combination of thick plates is 32mm+32mm, and the mechanical properties are: yield strength R eL : 510MPa, tensile strength R m :655MPa, Elongation A: 21%, -40 o CKV 2 Impact energy: 127J substrate test plate; test plate size is 600mm×400mm×32mm;

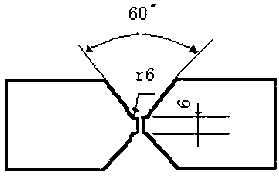

[0031] The groove shape of submerged arc welding is a double-sided U symmetrical groove, the groove angle is 60°, and the blunt edge is 6mm and R6mm;

[0032] Welding material matching: welding wire diameter Ф4.0mm, flux is SJ105Q, mechanical property of deposited metal is R el =614MPa, R m =709 MPa, A=23%, Z=73%, -40℃KV 2 Impact energy = 145J;

[0033] Welding process parameters: welding current 700A, welding voltage 32V, welding speed 29~30cm / min, welding line energy 45 kJ / cm.

[0034] The base material test plate was butt welded by multi-layer and multi-pass continuous welding, and the interlayer temperature was controlled at 180~190°C. Under the premise of not preheating before welding an...

Embodiment 2

[0036] Substrate for bridges: the combination of thick plates is 32mm+32mm, and the mechanical properties are: yield strength R eL : 553MPa, tensile strength R m :661MPa, Elongation A: 22%, -40 o CKV 2 Impact energy: 125J substrate test plate; test plate size is 600mm×400mm×32mm;

[0037] The groove shape of submerged arc welding is a double-sided U symmetrical groove, the groove angle is 60°, and the blunt edge is 6mm and R6mm;

[0038] Welding material matching: welding wire diameter Ф4.0mm, flux is SJ105Q, mechanical property of deposited metal is R el =614MPa,R m =709 MPa, A=23%, Z=73%, -40℃KV 2 Impact energy = 145J;

[0039] Welding process parameters: welding current 750A, welding voltage 32V, welding speed 25~26cm / min, welding line energy 55 kJ / cm.

[0040] The base material test plate was butt welded by multi-layer and multi-pass continuous welding, and the interlayer temperature was controlled at 190~210°C. Without preheating before welding and heat treatment a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com