A mobile overturning vehicle for making floor boxes

A mobile, flip-car technology, applied in the direction of manufacturing tools, ceramic molding machines, molds, etc., can solve the problems of high production cost, cumbersome production process and low production efficiency of the floor box body, so as to achieve no need for frequent maintenance, structural Robust, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] With reference to the accompanying drawings, the present invention will be further described. However, the present invention is not limited within the scope of the structure shown in this embodiment and the accompanying drawings.

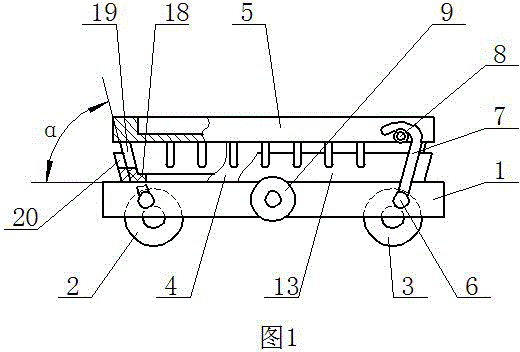

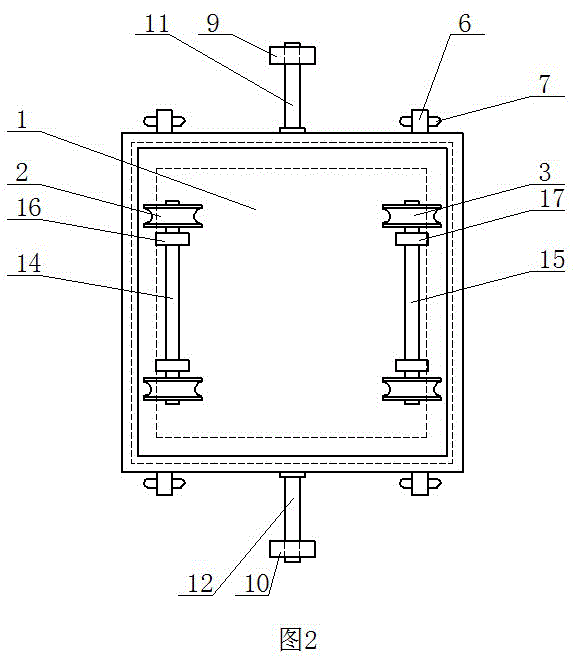

[0008] figure 1 In the shown structure, 1 is the base, the base 1 is rectangular, the support shaft is fixed on the base 1, the moving wheel is installed on the support shaft, and the support rod is installed on the base 1 at a position parallel to the axis of the support shaft. The side extends outward to the outside of the moving wheel, the outer end of the support rod is equipped with rollers, the upper surface of the base 1 is equipped with a mold 13, the mold 13 is rectangular, and the upper end of the mold 13 is equipped with a fastening cover 5, that is: the fastening cover 5 and the mold 13 The concrete face of the floor box product inside. The mold 13 described in the above structure can adopt various structures, as long as the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com