Oil well cement maintenance kettle

A technology for oil well cement and curing kettle, which is applied to ceramic molding machines, manufacturing tools, etc., can solve the problems of strip test block maintenance, inability to achieve constant pressure heating and constant pressure cooling, and inability to test the flexural performance of oil well cement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

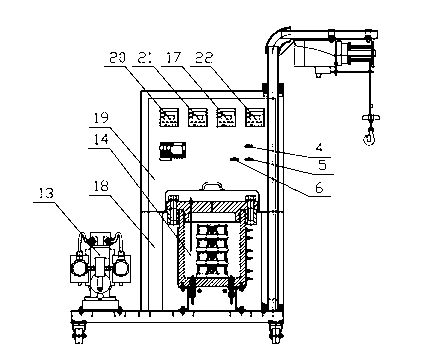

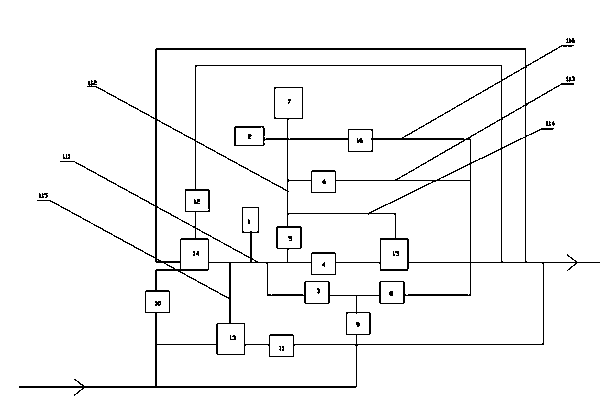

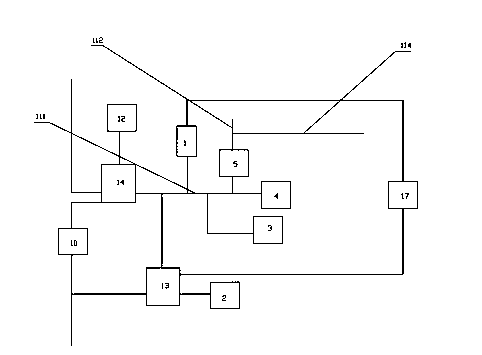

[0059] Below in conjunction with accompanying drawing, the present invention is further described:

[0060] An oil well cement curing kettle, comprising a box body 18, a kettle body 14 and a control panel 19, the control panel 19 is arranged on the box body 18, the box body 18 is provided with a kettle body installation cavity, and also includes a constant pressure pressure control system, the constant pressure pressure control system includes a back pressure controller 15, a back pressure accumulator 7 and a connecting pipeline I111, the back pressure controller 15 communicates with the kettle body 14 through the connecting pipeline I111, and the connecting pipeline I111 communicates with Connecting pipeline II112, one end of the connecting pipeline II112 communicates with the connecting pipeline I111, and the other end communicates with the back pressure accumulator 7; the connecting pipeline I111 is provided with a pressure control valve 4, and the connecting pipeline II112 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com