Machine-made dry-mixed plaster mortar suitable for mechanized spraying

A plastering mortar and machine-made sand technology, which is applied in the field of machine-made sand dry-mixed plastering mortar and dry-mixed plastering mortar, and can solve the problems of machine-made sand with many edges and corners, inability to adapt to mechanized spraying, and poor fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

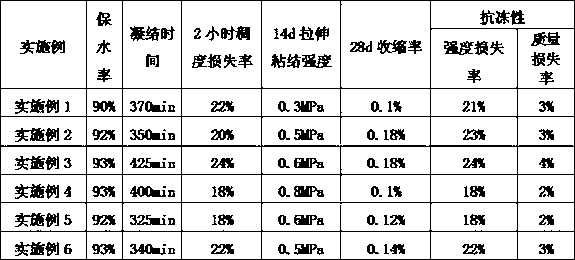

[0018] Table 1

[0019]

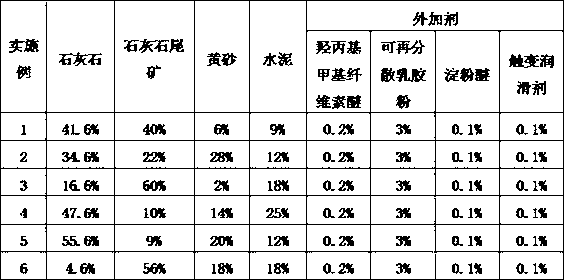

[0020] Performance Testing

[0021] Test the water retention, setting time, 14d tensile bond strength, 28d shrinkage and frost resistance of the mortar of the present invention respectively according to the relevant regulations of JGJ / T70, according to Appendix A "Consistency Loss Rate Test Method" in GB-T25181-2010 The relevant regulations test the 2-hour consistency loss rate of the mortar of the present invention, and the test results are shown in Table 2.

[0022] Table 2

[0023]

[0024] According to JGJ / T70 standard test 28d compressive strength, the test results are as follows:

Embodiment 1

[0025] Embodiment 1 is the intensity grade of M5, and test result is 6.2MPa;

Embodiment 2

[0026] Embodiment 2 is the strength grade of M10, and test result is 10.6MPa;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com