A ferritic bainite advanced high-strength steel plate and its manufacturing method

A high-strength steel plate and a manufacturing method technology, applied in the field of advanced high-strength steel plates, can solve the problems of reduced rolling line production efficiency, complex production process, high Nb content, and achieve excellent cold bending performance, high cost advantage, and improved strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 The molten steel smelted according to the proportions in Table 3 is vacuum degassed and then continuously cast or die casted. The thickness of the slab is 100mm. After multiple passes of rolling within the range, it is rolled into a steel plate with a thickness of 2mm, the total reduction rate is 98%, and the final rolling temperature is 840°C, then water-cooled at 100°C / s to 650°C for 4 seconds, and then cooled at 70°C / s sWater cooled to 450°C Air cooled to room temperature without tempering.

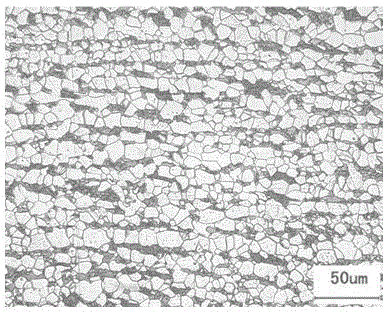

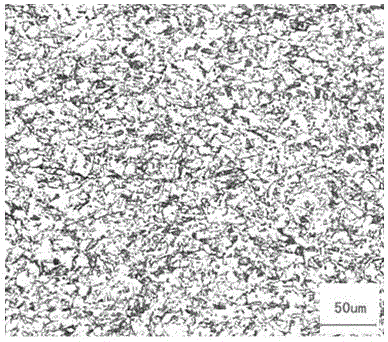

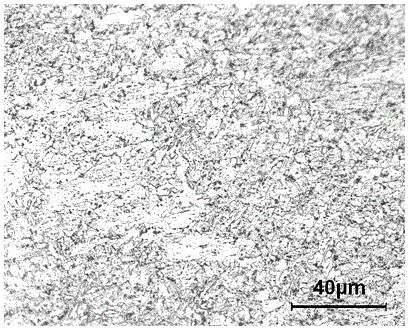

[0048] The detailed components and process parameters of Examples 2-5 are shown in Table 3 and Table 4. The implementation process is similar to that of Example 1. Tempering treatment is required in Examples 4 and 5. The properties of the steel plates obtained in all examples are shown in Table 5. . The metallographic structure of part of the steel plate of the embodiment of the present invention is as follows: figure 1 , figure 2 and image 3 shown.

[0049] Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com