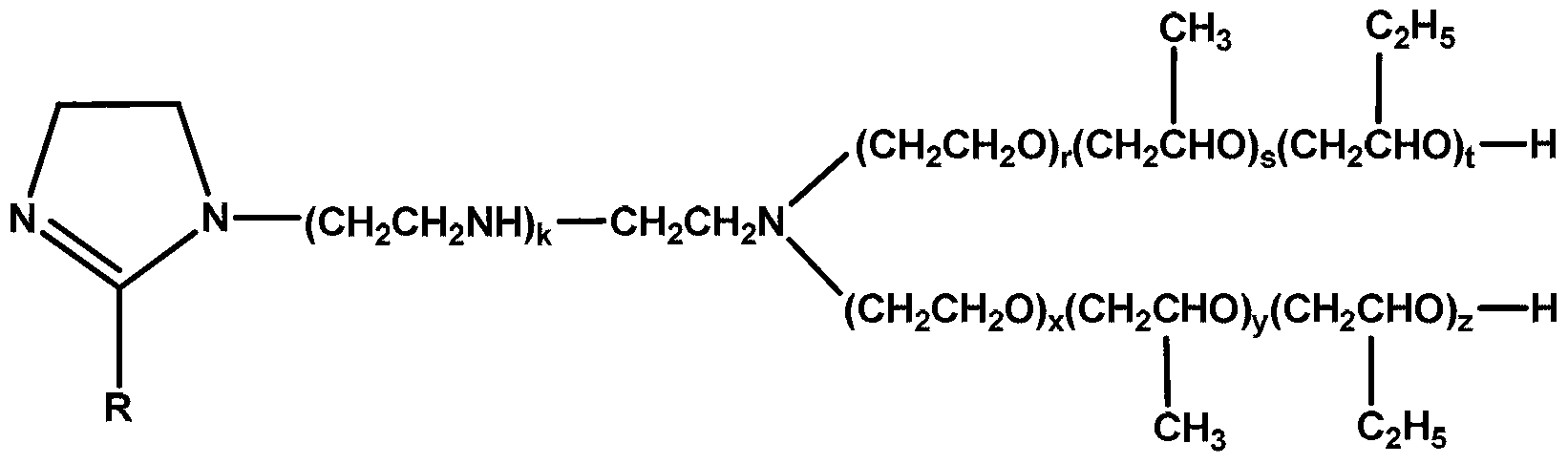

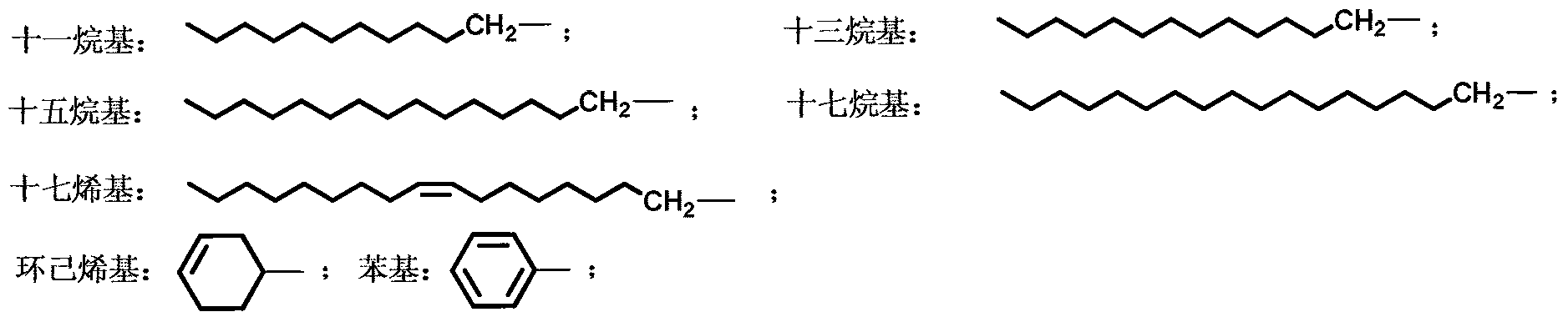

Water-soluble non-ionic imidazoline corrosion inhibitor and preparation method thereof

A type of imidazoline and corrosion inhibitor technology, applied in the field of water-soluble non-ionic imidazoline corrosion inhibitor and its preparation, can solve the problems of limited use, affecting the use effect, poor water solubility, etc., and achieve excellent corrosion inhibition performance , Good water solubility and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

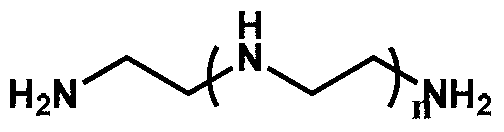

[0026] Add 103.00g (1mol) of diethylenetriamine and 200.00g (1mol) of lauric acid into a 2L high-temperature reactor equipped with mechanical stirring, condenser, water separator and temperature sensor, add 500.00g of water-carrying agent toluene and Dehydration catalyst Al 2 o 3 0.30g, through N 2 Exclude the air in the system, and raise the temperature to 200°C to dehydrate the reactant. After the amount of dehydration reaches 32.40ml, evaporate the water-carrying agent toluene to obtain a brown viscous liquid. Transfer this brown viscous liquid to 2L pressure reactor, add etherification catalyst KOH0.30g, pass N 2 Exclude the air in the system, raise the temperature to 150°C, and feed 660.00g (15mol) of ethylene oxide to carry out the etherification reaction; after the reaction pressure no longer drops, continue to feed 174.00g (3mol) of propylene oxide to carry out the etherification reaction; After the reaction pressure no longer drops, continue to feed 144.00g (2mol) ...

Embodiment 2

[0030] Add 103.00g (1mol) of diethylenetriamine and 284.00g (1mol) of stearic acid into a 2L high-temperature reactor equipped with mechanical stirring, condenser, water separator and temperature sensor, and add 800.00g of water-carrying agent toluene And dehydration catalyst platinum 0.04g, pass N 2 Exclude the air in the system, and raise the temperature to 240°C to dehydrate the reactant. After the amount of dehydration reaches 32.40ml, evaporate the water-carrying agent toluene to obtain a brown viscous liquid. Transfer this brown viscous liquid to 2L pressure reactor, add etherification catalyst NaOH0.90g, pass N 2 Exclude the air in the system, raise the temperature to 140°C, and pass in 116.00g (2mol) of propylene oxide to carry out the etherification reaction; after the reaction pressure no longer drops, continue to pass in 528.00g (12mol) of ethylene oxide to carry out the etherification reaction; After the reaction pressure no longer drops, continue to feed 288.00g ...

Embodiment 3

[0034] Add 146.00g (1mol) of triethylenetetramine and 282.00g (1mol) of oleic acid into a 2L high-temperature reactor equipped with mechanical stirring, condenser, water separator and temperature sensor, and add 900.00g of water-carrying agent xylene And dehydration catalyst tetrabutylammonium bromide 0.50g, logical N 2 Exclude the air in the system, and raise the temperature to 180°C to dehydrate the reactant. After the dehydration amount reaches 32.40ml, distill out the water-carrying agent xylene to obtain a brown viscous liquid. Transfer this brown viscous liquid to 2L pressure reactor, add etherification catalyst CH 3 ONa0.50g, through N 2 Exclude the air in the system, raise the temperature to 120°C, and feed 144.00g (2mol) of 1,2-epoxybutane to carry out the butyric etherification reaction; after the reaction pressure no longer drops, continue to feed 440.00g (10mol) of epoxy Carry out the etherification reaction of ethane; after the reaction pressure no longer drops,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com