Curtain wall hanging profile and horizontal dry curtain wall hanging installation method

An installation method and curtain wall technology, which is applied to the processing of walls, building materials, and building components, can solve the problems of structural strength damage of the original curtain wall, slow construction speed, dust and noise, etc., and achieve simple structure, fast construction, and reduced Effects of dust and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

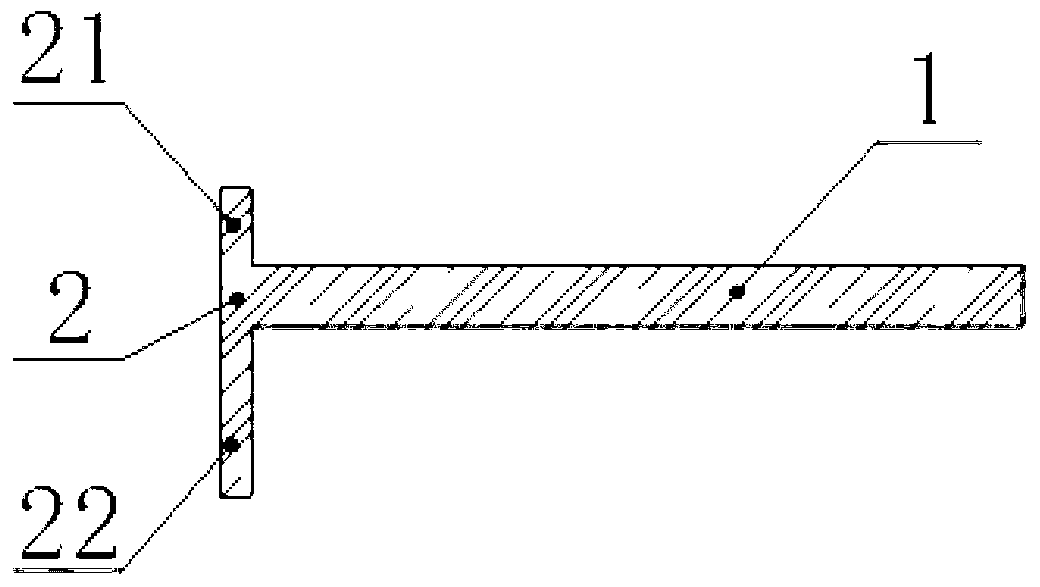

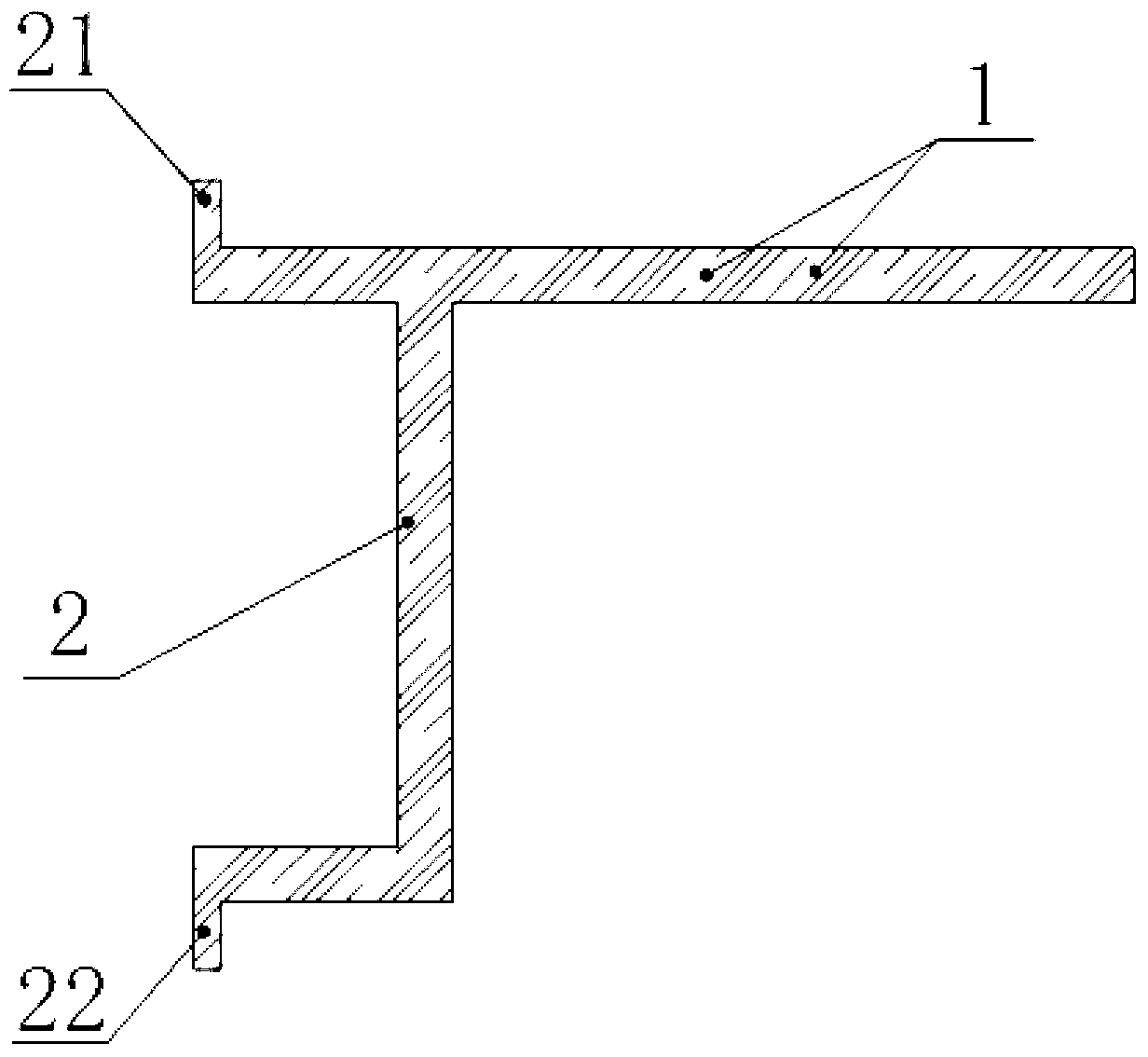

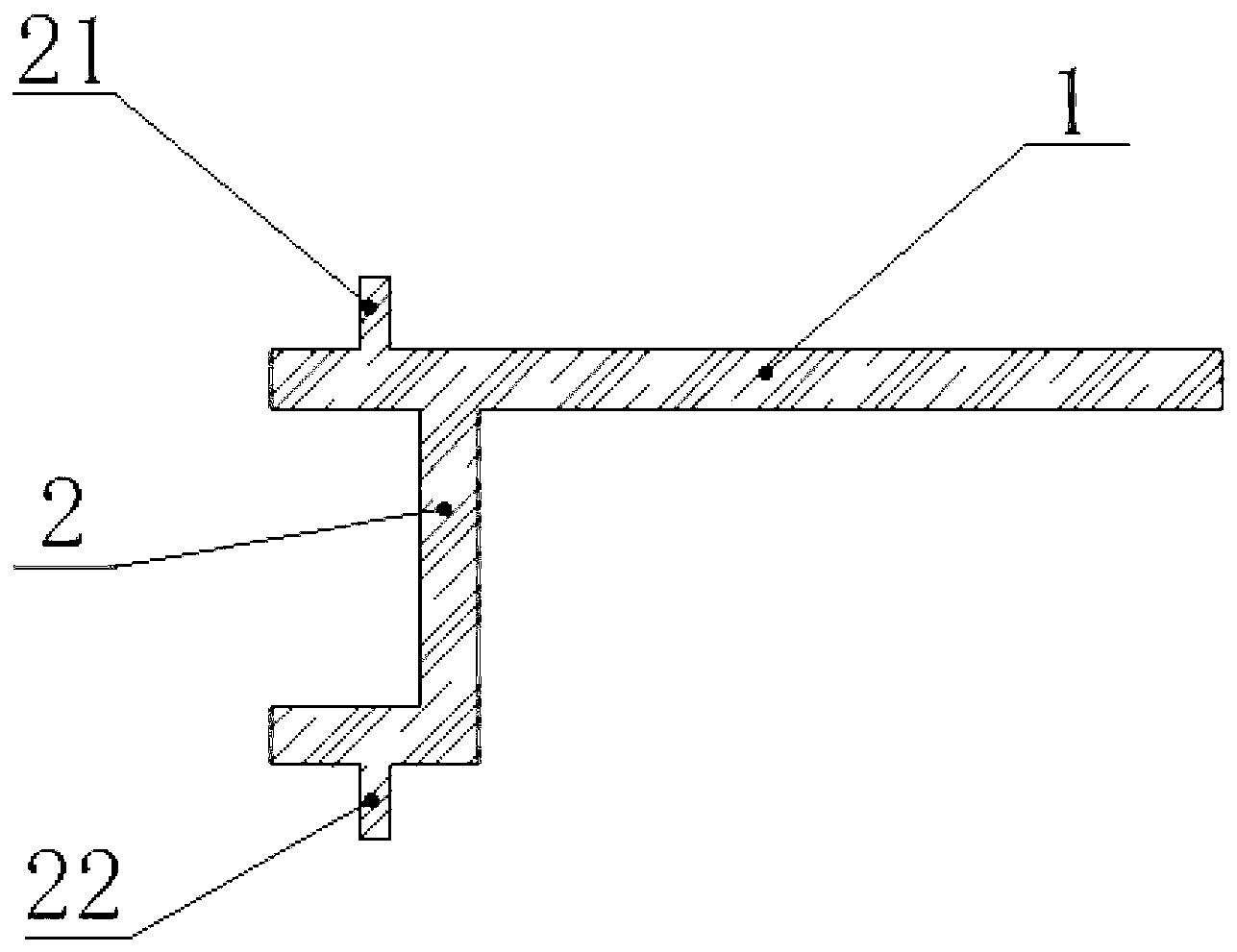

[0021] Such as Figure 1-3 The curtain wall hanging profile shown is made of 6063-T5 aluminum alloy material treated with fluorocarbon baking paint or anodic color development. It includes a connecting part 1 and a hanging part 2 located at one end of the connecting part 1 ; the hanging part 2 has an upward upper hook 21 and a downward lower hook 22 .

[0022] Such as figure 1 The profile section shown is "T" shaped.

[0023] Such as figure 2 The profile hanging part 2 shown has an open cross section, and the upper hook 21 and the lower hook 22 are respectively located at the edge of the opening. Curtain wall materials of the same color or different colors can be placed in the openings as belts or decorative strips. Because they present different planes, it reflects the three-dimensional effect of the overall wall surface, expressing its diversity and liveliness.

[0024] Such as image 3 The profile hanging part 2 shown has an open cross section, and the upper hook 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com