Shield tunnel pipe piece designing method taking double-liquid synchronous grouting layer performance degradation into consideration

A shield tunnel segment and synchronous grouting technology, which is applied in tunnels, tunnel linings, mining equipment, etc., can solve problems such as rock formation danger, low resistance coefficient and strength of grouting ring, and difficulty in spreading grout, so as to ensure long-term safety , the result is real and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0051] Design the shield tunnel segment according to the following steps:

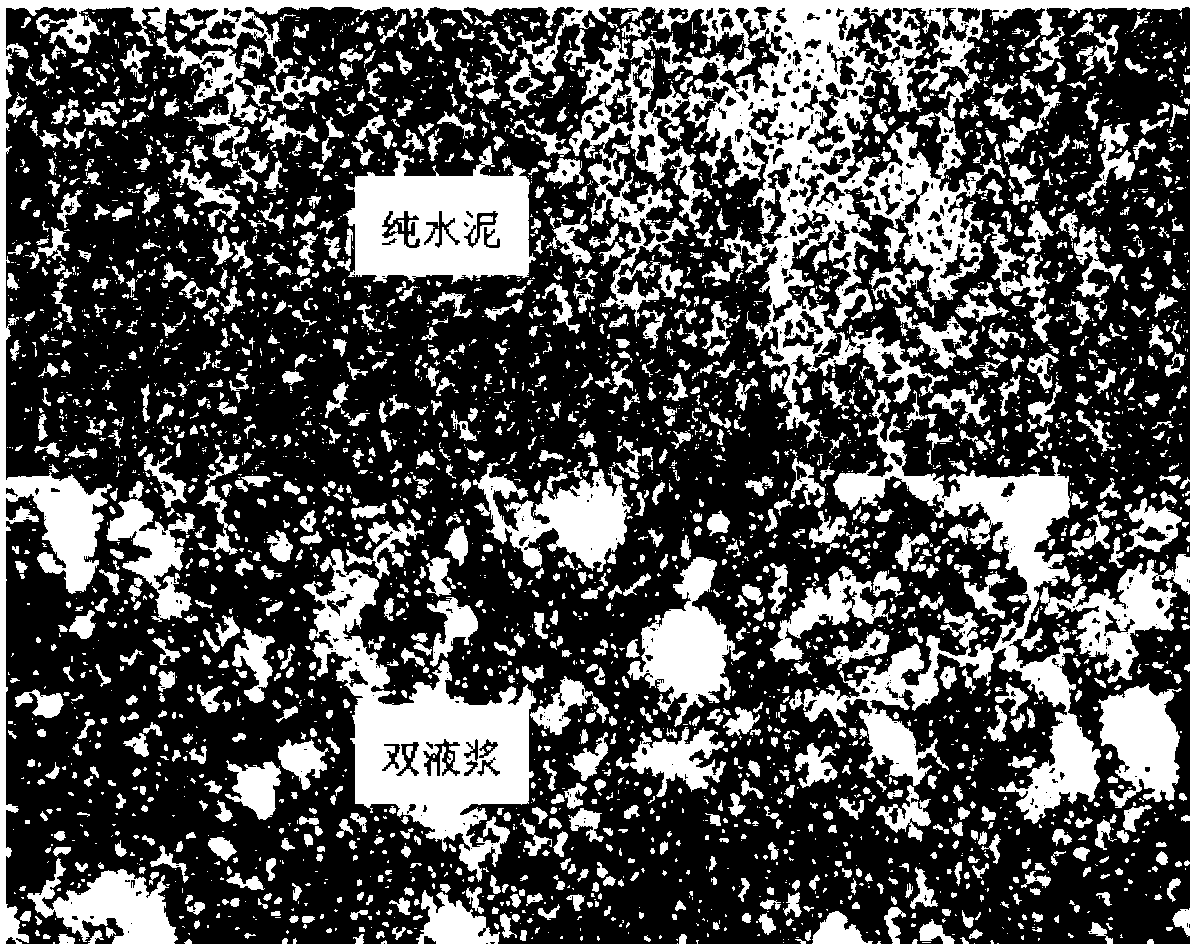

[0052] Step (1): If image 3 As shown, through the comparative analysis of the mesostructure of the pure cement specimen slices and the double-fluid specimen slices, it can be found that under the three-dimensional video microscope, the image of the double-fluid specimen slices contains white spot-like distribution of the lens, while the pure cement This phenomenon does not appear in the images of the specimen slices, and it can be inferred that the white crystalline substance is the product of the reaction between cement and water glass-gelatinous calcium silicate. And based on this, three different distribution forms of cement and water glass reaction products in the cement-water glass double slurry specimen after water glass failure were determined: the cement-water glass double slurry wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com