Motorcycle secondary air compensating valve

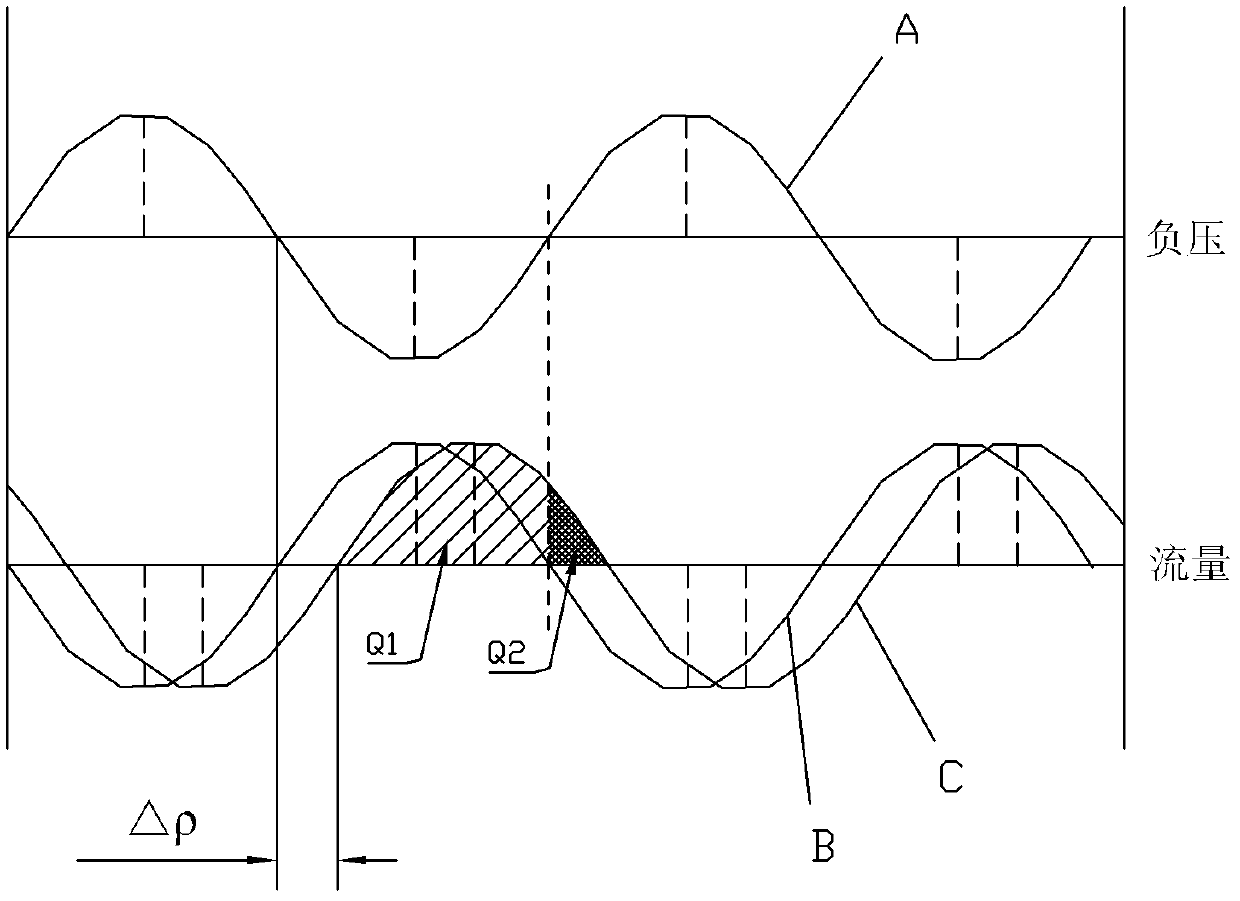

A technology for motorcycles and air supplement valves, applied in the direction of exhaust devices, mufflers, engine components, etc., can solve the problems of cut-off delay, reed valve fresh air cannot enter, valve lag, etc., to reduce pollution and structure Simple and reasonable, the effect of increasing the gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

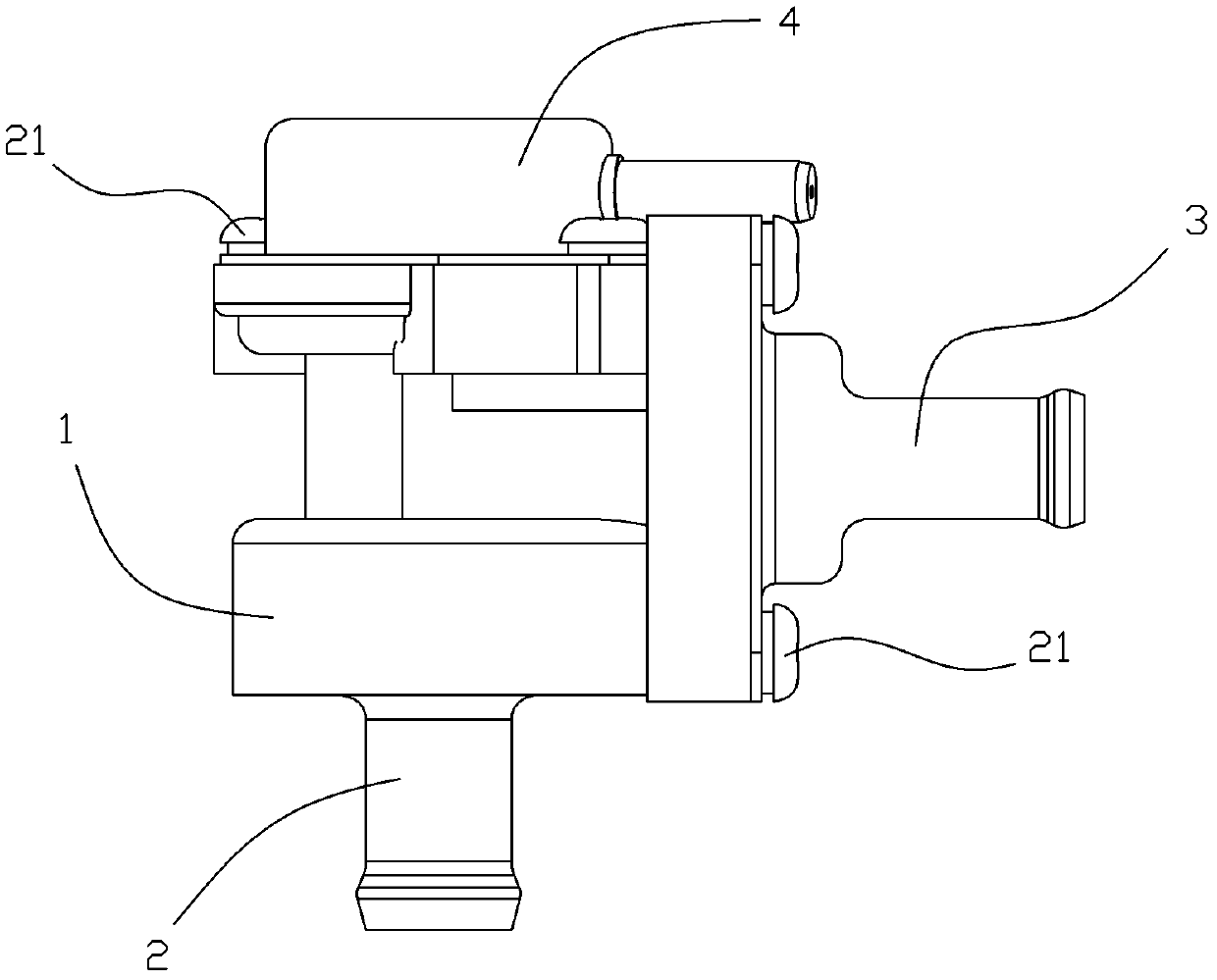

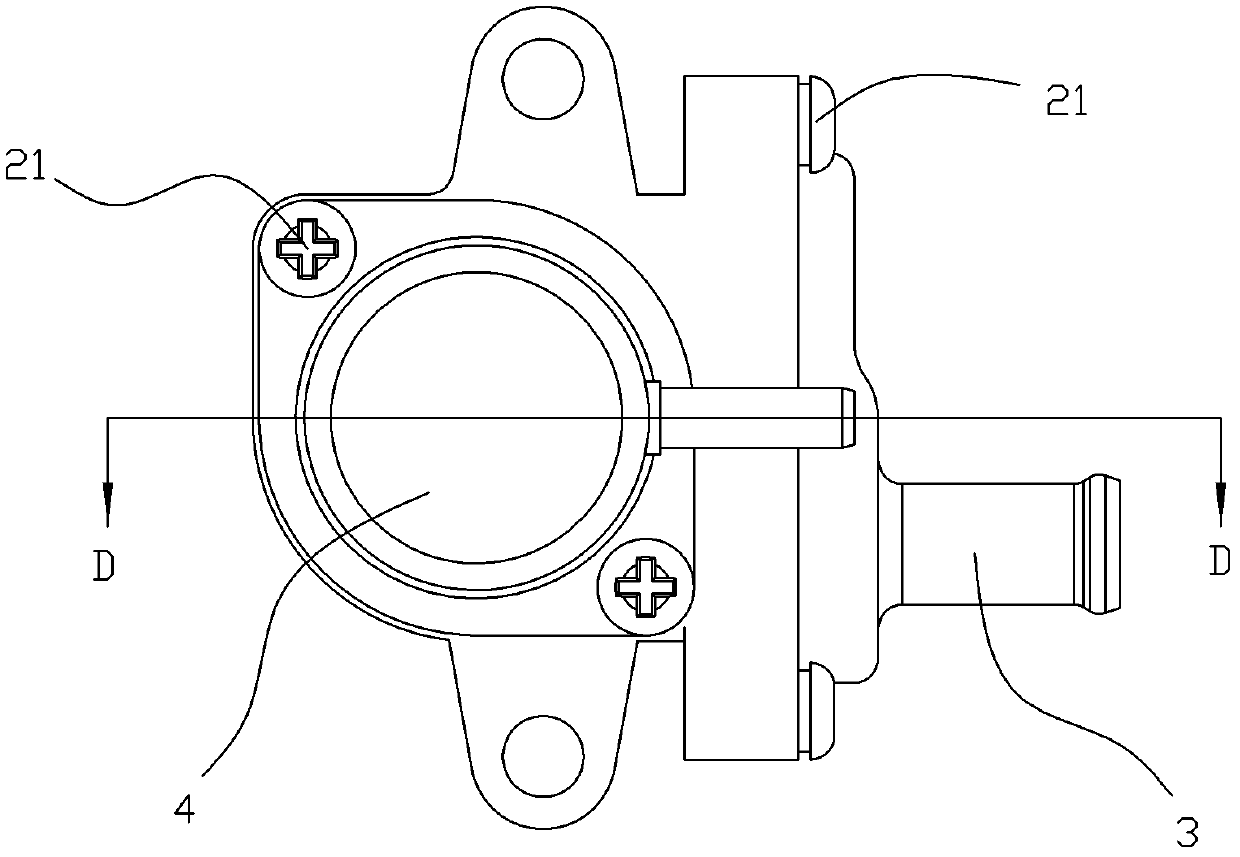

[0017] refer to Figure 1~Figure 4 , a motorcycle secondary air supply valve of the present invention, which includes a valve body 1 provided with an air intake chamber 11, an air outlet chamber 12 and a negative pressure chamber 13, on the inlet and outlet chambers 11, 12 and the negative pressure chamber 13 Air inlet and outlet pipes 2, 3 and negative pressure pipe 4 are respectively arranged, and air inlet and outlet pipes 2, 3 and negative pressure pipe 4 are respectively composed of a tubular body and a basin-shaped cover arranged at one end of the tubular body, and the tubular body and the basin-shaped cover Integral molding, there are three concave cavities on the valve body 1, and the basin-shaped cover is installed opposite to the concave cavities to form the air inlet chamber 11, the air outlet chamber 12 and the negative pressure chamber 13; the air inlet pipe 2 is arranged on the air inlet pipe 2 The pot-shaped cover at one end is pressed and fitted on the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com