Wind driven generator wind wheel provided with straight panel wind wheel blades

A technology of wind turbines and wind rotor blades, applied in the field of wind rotors, can solve the problems of narrow effective use range of wind speed, low efficiency of wind energy absorption, waste of wind energy resources, etc., achieve reduced centrifugal force, enhanced ability to absorb strong wind resources, and reduce sharp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

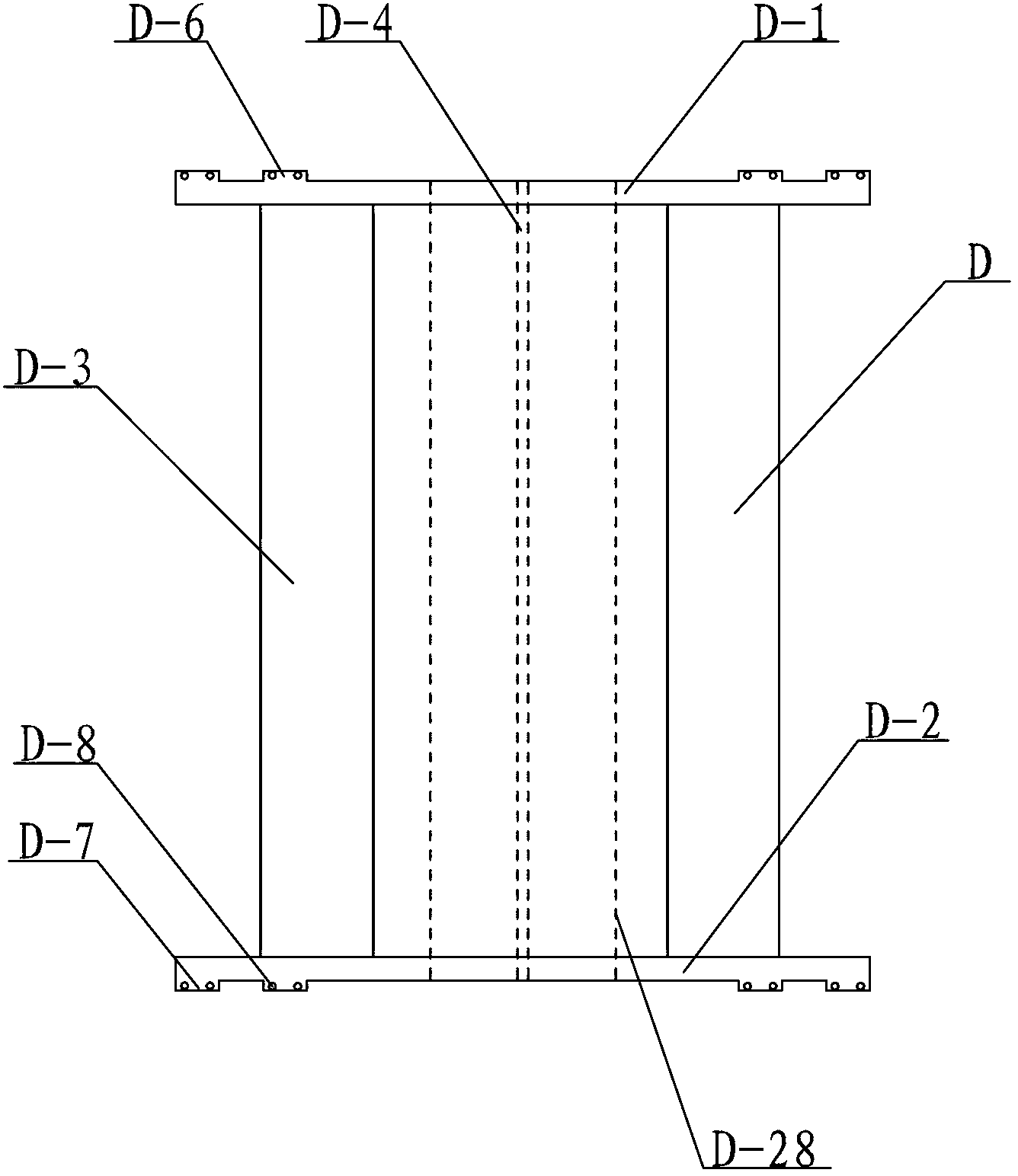

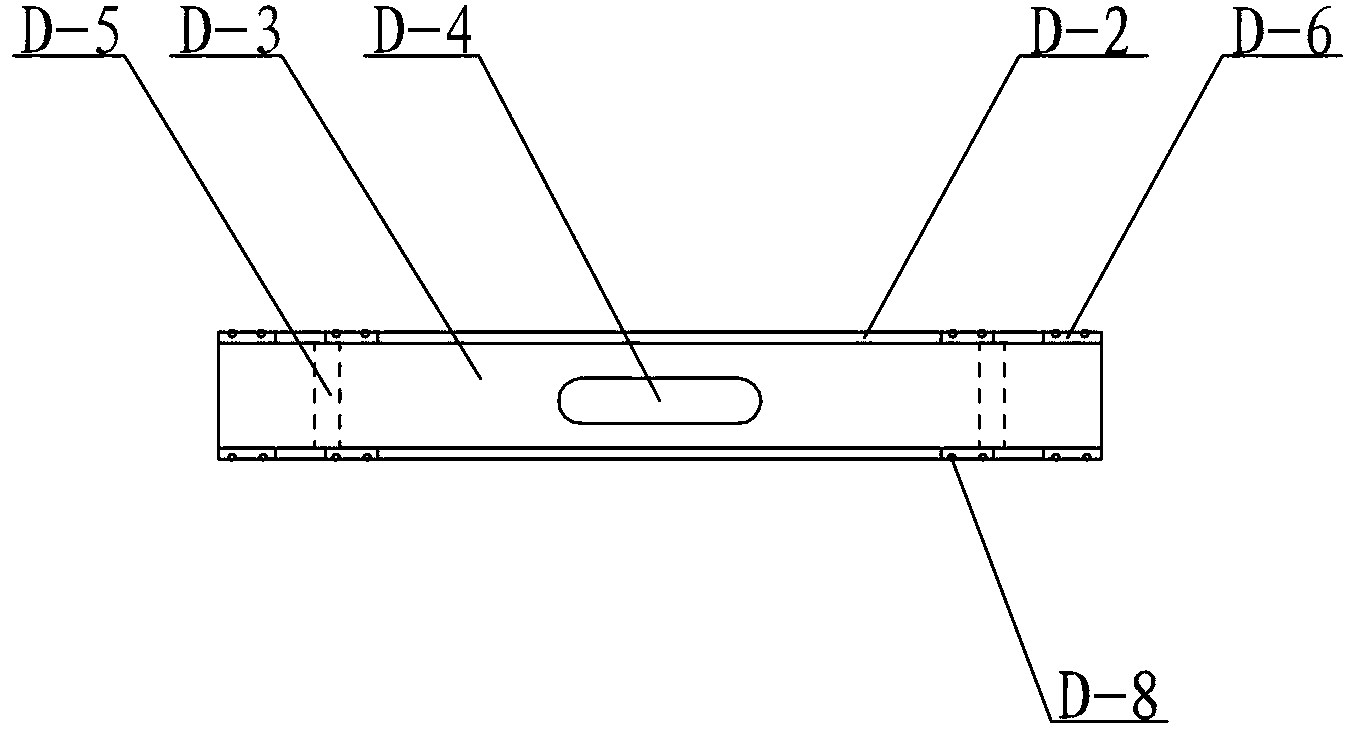

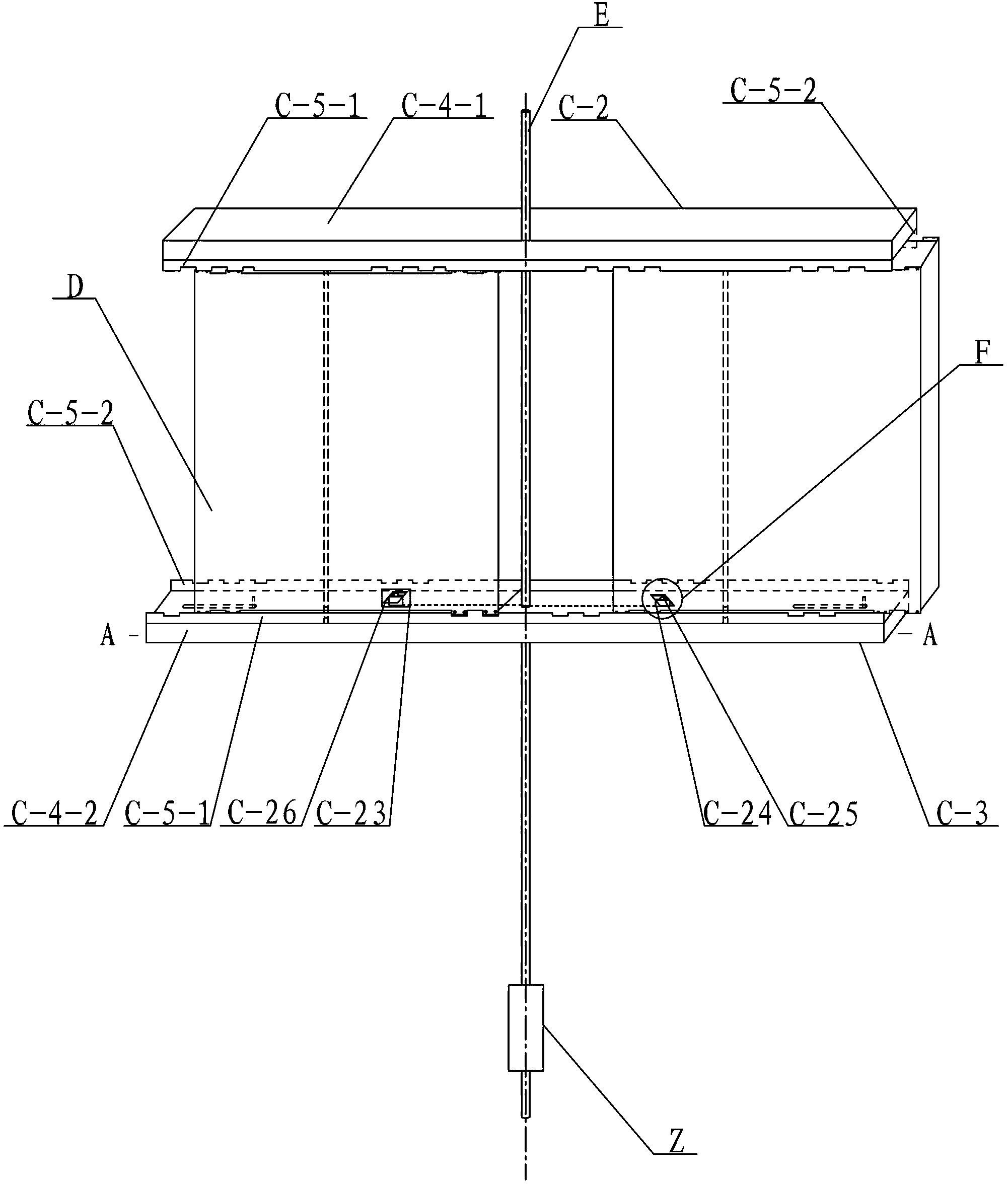

[0018] Specific implementation mode one: combine Figure 1-Figure 7 Describe this embodiment, this embodiment includes a tower body, a main shaft E and a plurality of straight wind rotor blades D, the main shaft E is vertically arranged, the tower body includes multiple sets of towers C, and one end of the multiple sets of towers C is fixed to the main shaft On E, the other ends of multiple sets of towers C are distributed horizontally and radially at equal angles relative to the main axis E, and each set of towers C is equipped with a straight wind rotor blade D,

[0019] Each group of towers C includes an upper tower C-2 and a lower tower C-3, and the upper tower C-2 and the lower tower C-3 are arranged relatively parallel up and down,

[0020] The upper tower C-2 includes a steel plate C-4-1, a first side plate C-5-1 and a second side plate C-5-2, and the first side plate C-5-1 and the second side plate C-5-2 is arranged on both sides of the steel plate C-4-1 in the length...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination image 3 and Figure 4 This embodiment will be described. The transmission device in this embodiment includes a first wind rotor blade shaft C-6, a second wind rotor blade shaft C-7, a first pin shaft C-8, a second pin shaft C-9, and a first sprocket C-10 , Second sprocket C-11, third sprocket C-12, fourth sprocket C-13, bracket C-14, first gear C-15, second gear C-16, third gear C-17 , the fourth gear C-18, the first chain C-19, the second chain C-20 and the third chain C-21,

[0026] The first wind rotor blade axis C-6 and the second wind rotor blade axis C-7 are centered on the main axis E, and are vertically symmetrical and rotatable to pass through the steel plate C-4-1, the main block D-28 and the shell C -4-2, and the first wind rotor blade shaft C-6 or the second wind rotor blade shaft C-7 is fixedly connected with the main block D-28 in the double-sided retractable block D-3, the main block The sheet D-28 forms ...

specific Embodiment approach 3

[0029] Specific implementation mode three: combination image 3 and Figure 4 To illustrate this embodiment, the tower C of this embodiment also includes a limiting device, and the limiting device includes two limiting cards C-23. In the center, a limit card slot C-26 is symmetrically provided, and the middle part of the bracket C-14 is horizontally rotatably arranged on the main shaft E in the two opposite housings C-4-2, and the two sides of the bracket C-14 A limit card C-23 is respectively fixed on the upper end surface of each, and the limit card C-23 is movably arranged in the limit card slot C-26. In this way, under the drive of the straight wind rotor blade D, the separation or meshing of the first gear C-15 and the third gear C-17, and the second gear C-16 and the fourth gear C-18 are realized through the limit device . When a straight wind rotor blade D is at an angle of 0 degrees, the second limit card C-25 in the limit device is pressed by the straight wind roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com