Numerical control tail-sealing machine

A technology of electronic control and single-board computer, which is applied in pyrotechnics, offensive equipment, weapon types, etc., to achieve the effects of convenient use and maintenance, elimination of stagnation, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

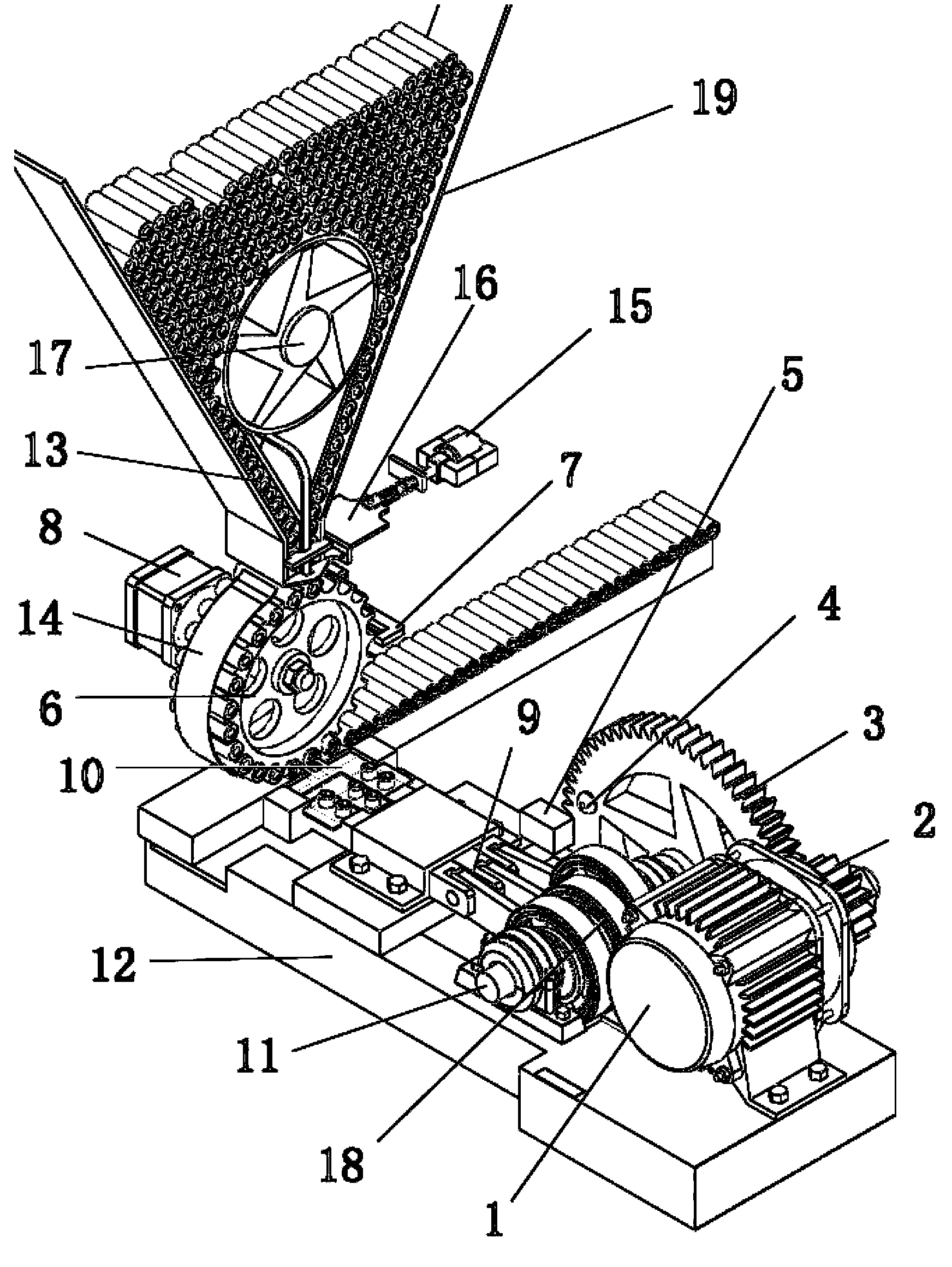

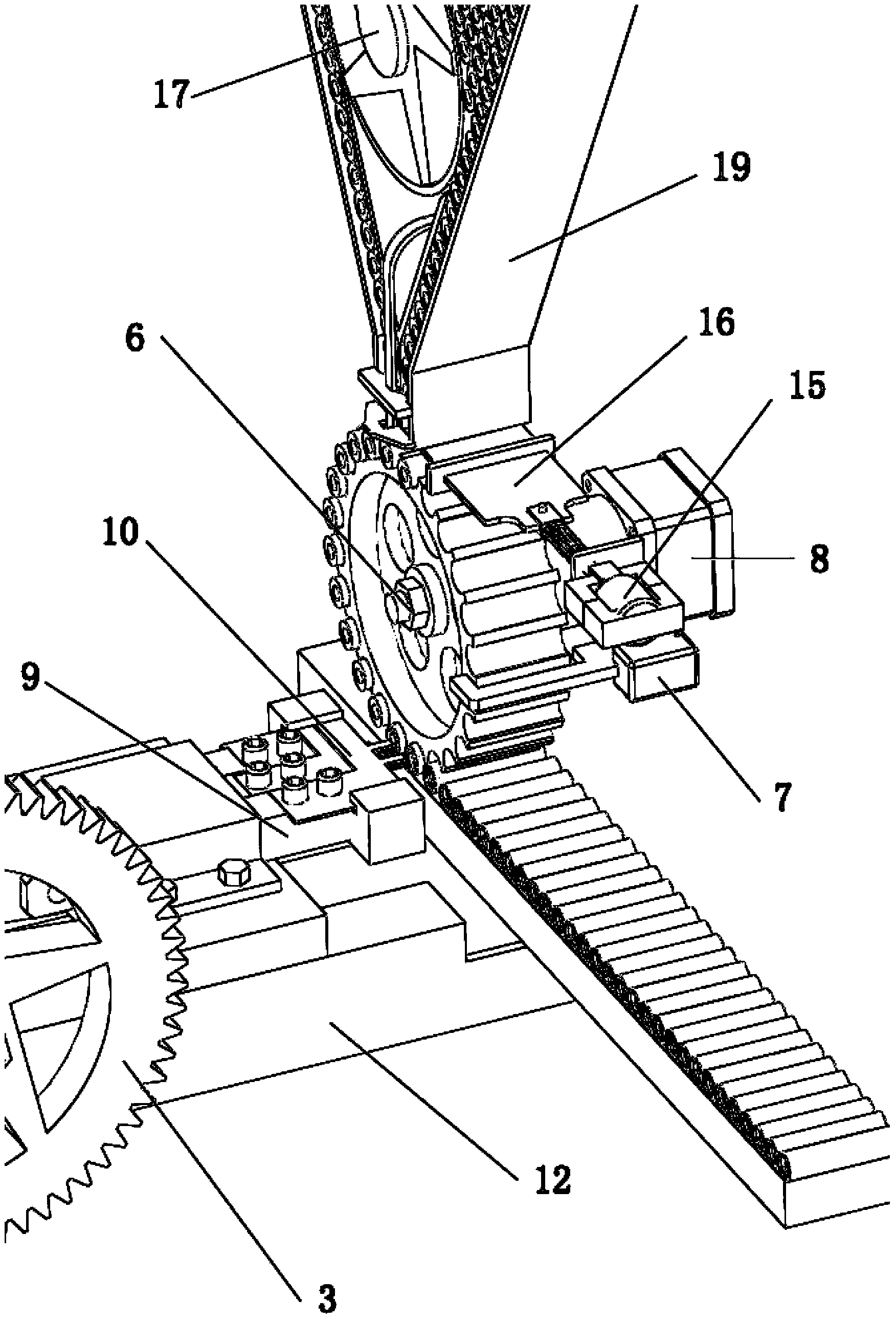

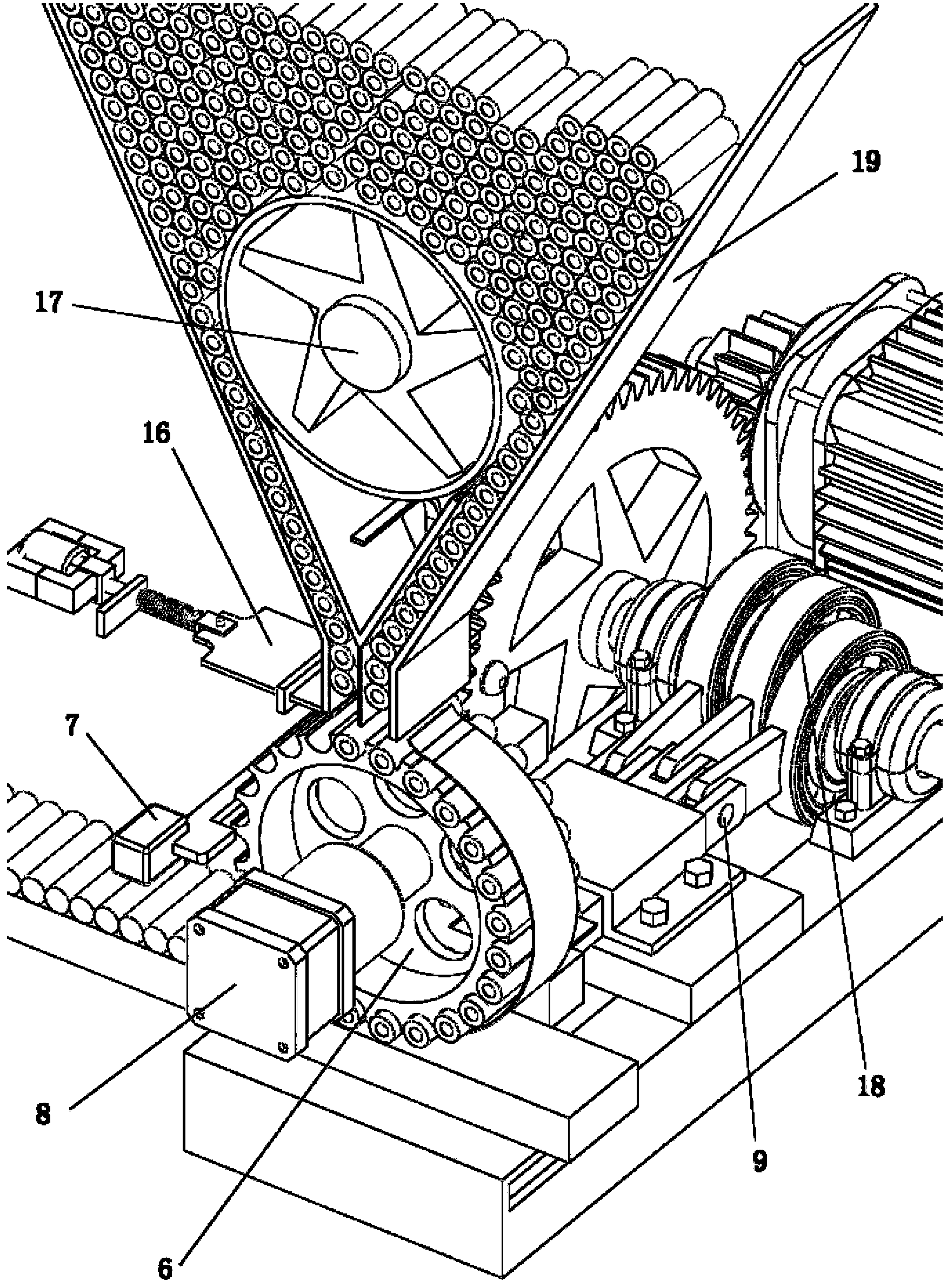

[0010] This technical scheme adopts a high-speed numerical control feeding device to replace the original mechanical feeding device. The high-speed numerical control feeding device mainly includes a double-barrel electric control drop gun box, a magnet 4, a Hall sensor 5, a photoelectric reset switch 7, a single-board computer, an electromagnet drive circuit, a stepping motor controller and a driver, a stepping motor Motor 8, sheave 6, keyboard, etc. Such as figure 1 shown (for the convenience of the above Figure 1-Figure 3 The end face baffle of the sheave on the side of the stepping motor is removed); the double-barreled electric control drop gun box is mainly composed of a V-shaped gun box 19, a runner 17, a gun path 13, a lower gun door 16, an electromagnet 15, etc. . Its function is that when the electromagnet drive circuit drives the electromagnet 15 to suck and pull the lower gun door 16 to open, the outlet of the V-shaped gun case has a pair of gun barrels that fal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com