Temperature cycle test device of aerated water rock

A temperature cycle and test device technology, applied in the field of testing machines, can solve the problems that the indoor test conditions cannot meet the actual requirements, cannot ensure that the rock samples are fully saturated with water, and the test results are not ideal, so as to achieve easy popularization and use, structure Simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

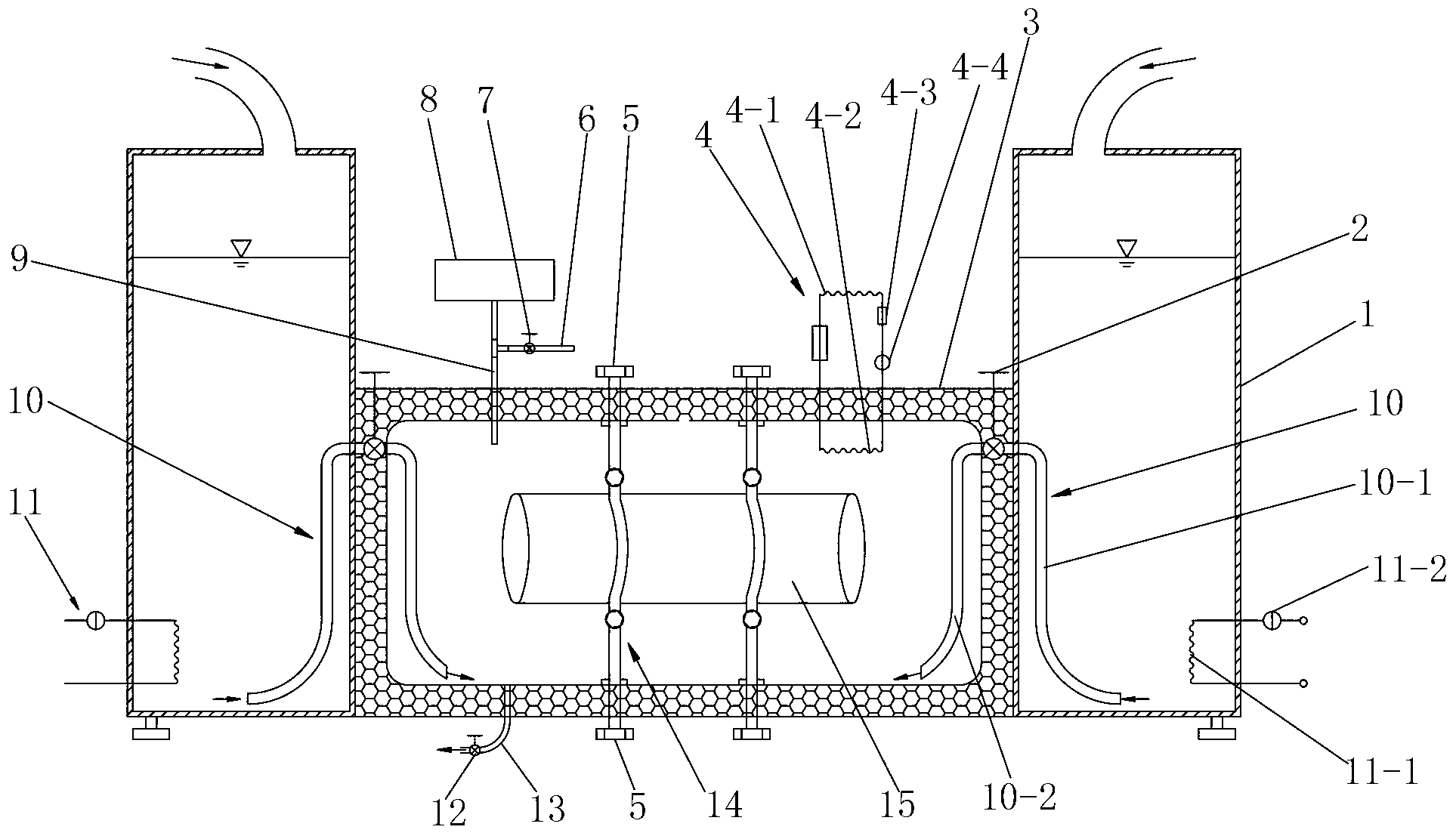

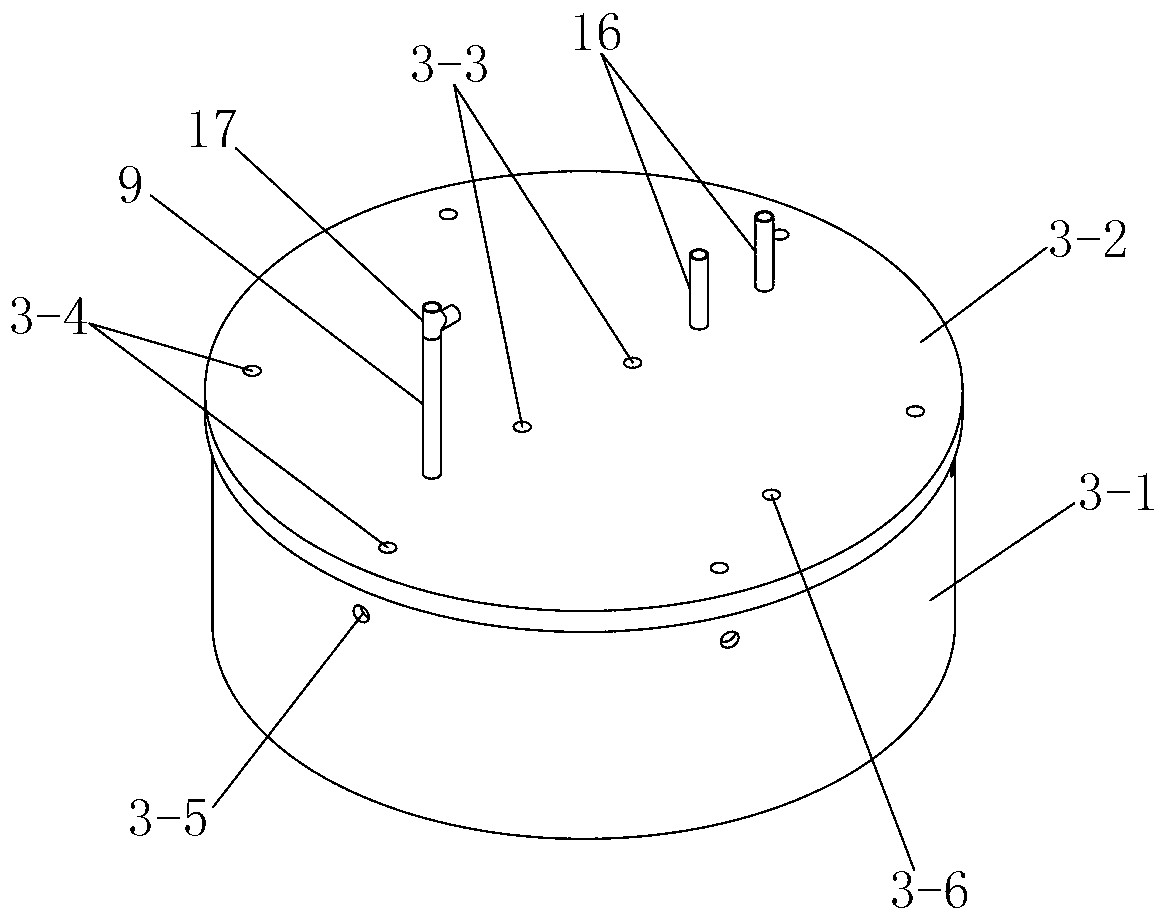

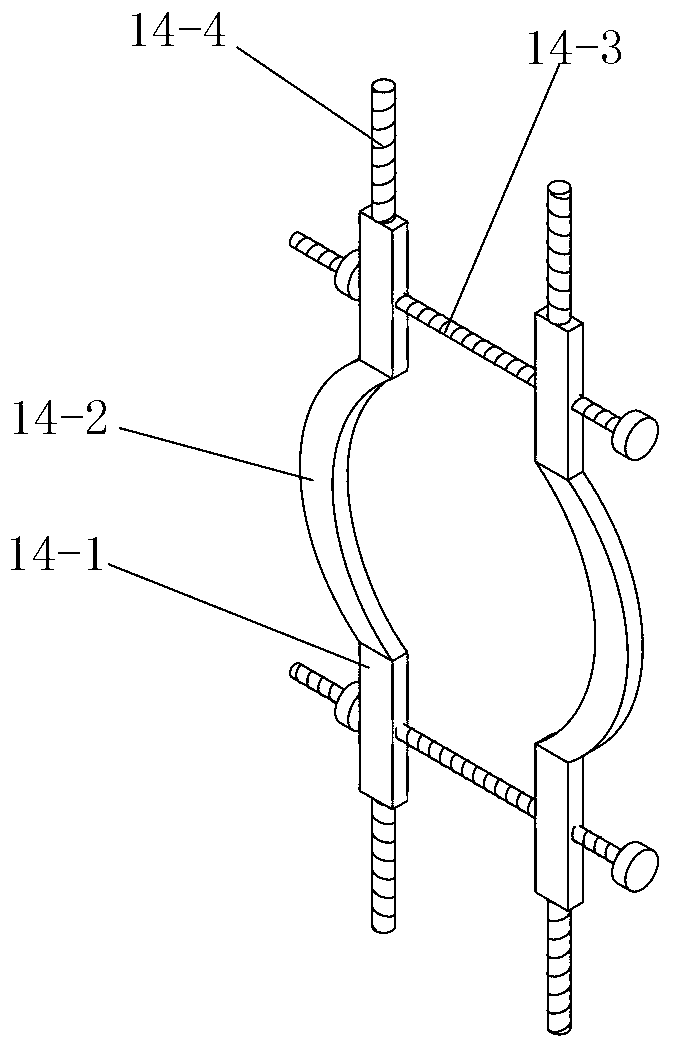

[0025] like figure 1 The shown temperature cycle test device for saturated rock blocks includes a thermal insulation saturated water chamber 3 and a water storage tank 1, and the thermal insulation saturated water chamber 3 and the water storage tank 1 are communicated through a water injection pipe 10, and the water injection pipe 10 is provided with The water inlet valve 2, the air pipe 9 and the cooling device 4 for cooling the gas in the heat preservation saturated water chamber 3 are provided on the said heat preservation saturated water chamber 3, and the air pipe 9 and the air input pipe 6 are used for cooling. The heat preservation and saturated water chamber 3 is connected to a vacuum pump 8 for vacuum treatment, an air inlet valve 7 is installed on the air input pipe 6, and a test piece fixture for fixing the rock block test piece 15 is arranged in the heat preservation and saturated water chamber 3. 14. A drain pipe 13 is connected to the bottom of the heat preserva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com