Aging method of lithium ion battery

A lithium-ion battery and voltage technology, applied in the field of aging process of lithium-ion batteries, can solve the problems of difficulty in picking out low-voltage batteries, prolonging the aging cycle, increasing time, labor, and logistics costs, so as to shorten the aging time and prevent inflow. market effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

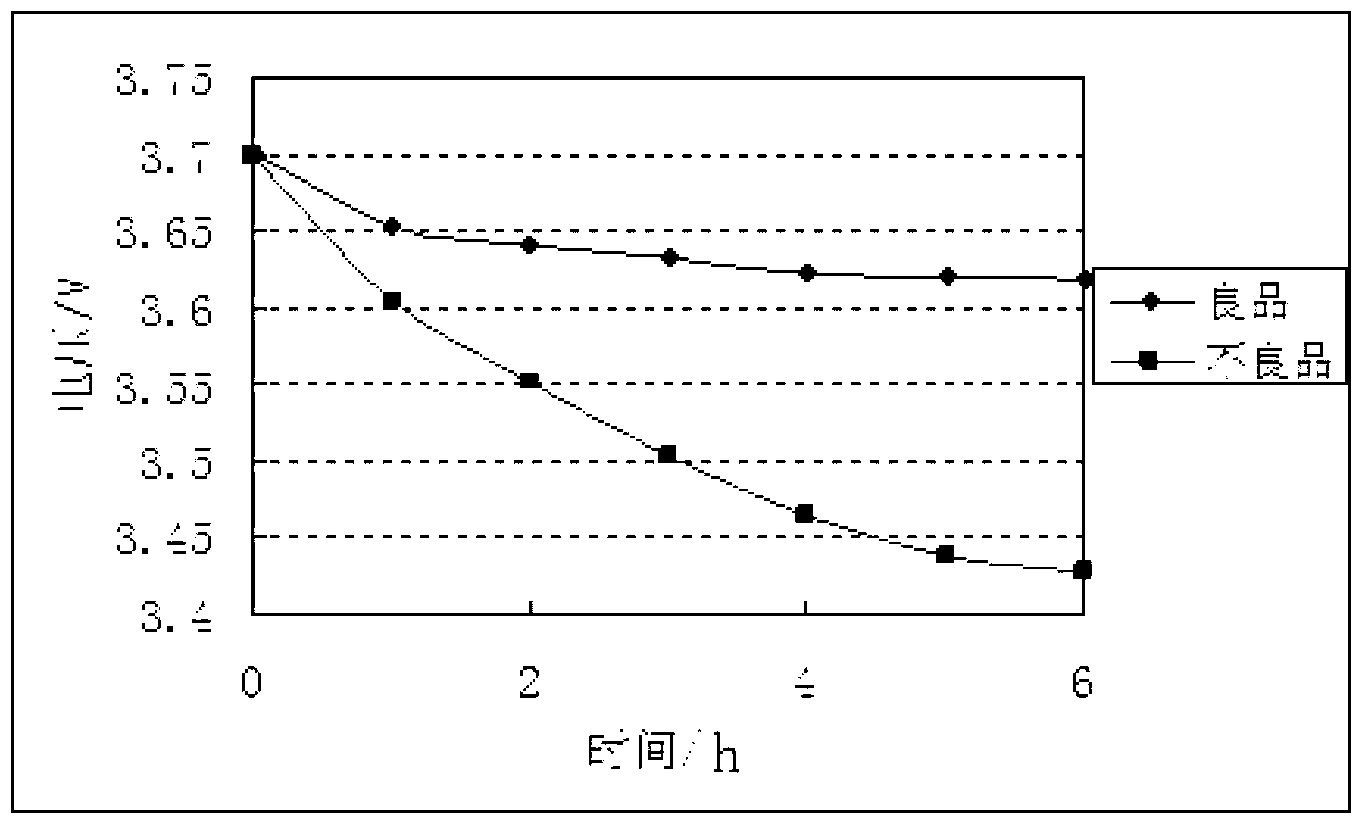

[0016] Example 1: Using lithium cobalt oxide as the positive electrode material, a polymer 554060P 1500mAh cell was made, charged to 3.700V with constant current and constant voltage, aged at 85.0°C for 6 hours (hours), and the voltage of the battery was tested. The voltage trend is as follows figure 1 As shown, there is a voltage difference of about 0.20V between the good product and the defective product after the battery is aged for 6 hours, and the defective product can be accurately picked out by measuring the voltage. The voltage difference is 0.05V, which means that the defective products may be picked out after the battery is aged for 1 hour. Here, the purpose of constant current and constant voltage charging is to maintain the voltage consistency of the battery before aging.

Embodiment 2

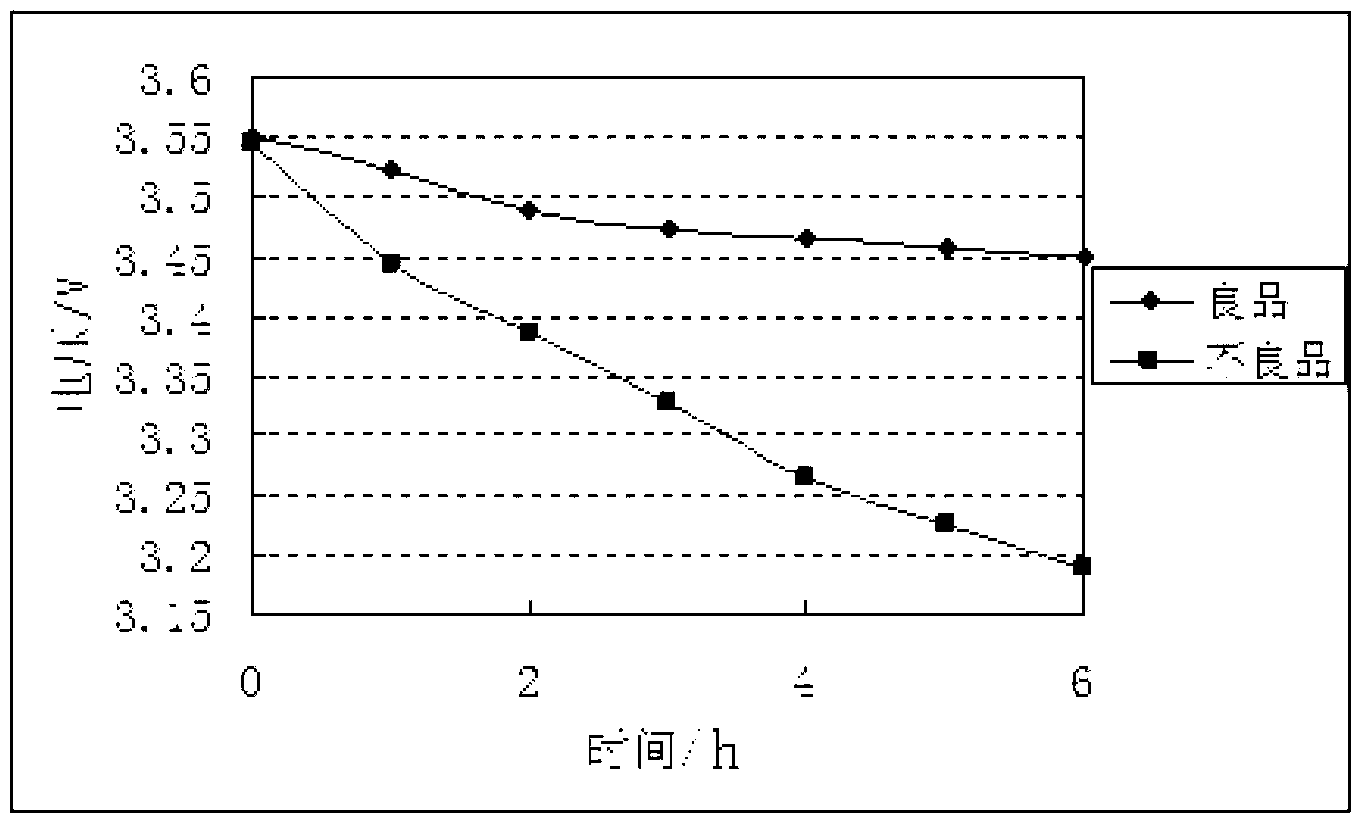

[0017] Example 2: Using lithium cobalt oxide as the positive electrode material, a polymer 554060P 1500mAh battery cell was made, charged to 3.550V with constant current and constant voltage, aged at 85.0°C for 6 hours, and the voltage of the battery was tested. The voltage trend is as follows figure 2 As shown, there is a voltage difference of more than 0.25V between the good product and the defective product after the battery is aged for 6 hours, and the defective product can be accurately picked out by measuring the voltage. Compared with Example 1, it shows that within a limited voltage range and other conditions are the same, the lower the voltage charged to the battery cell, the easier it is to distinguish defective products.

Embodiment 3

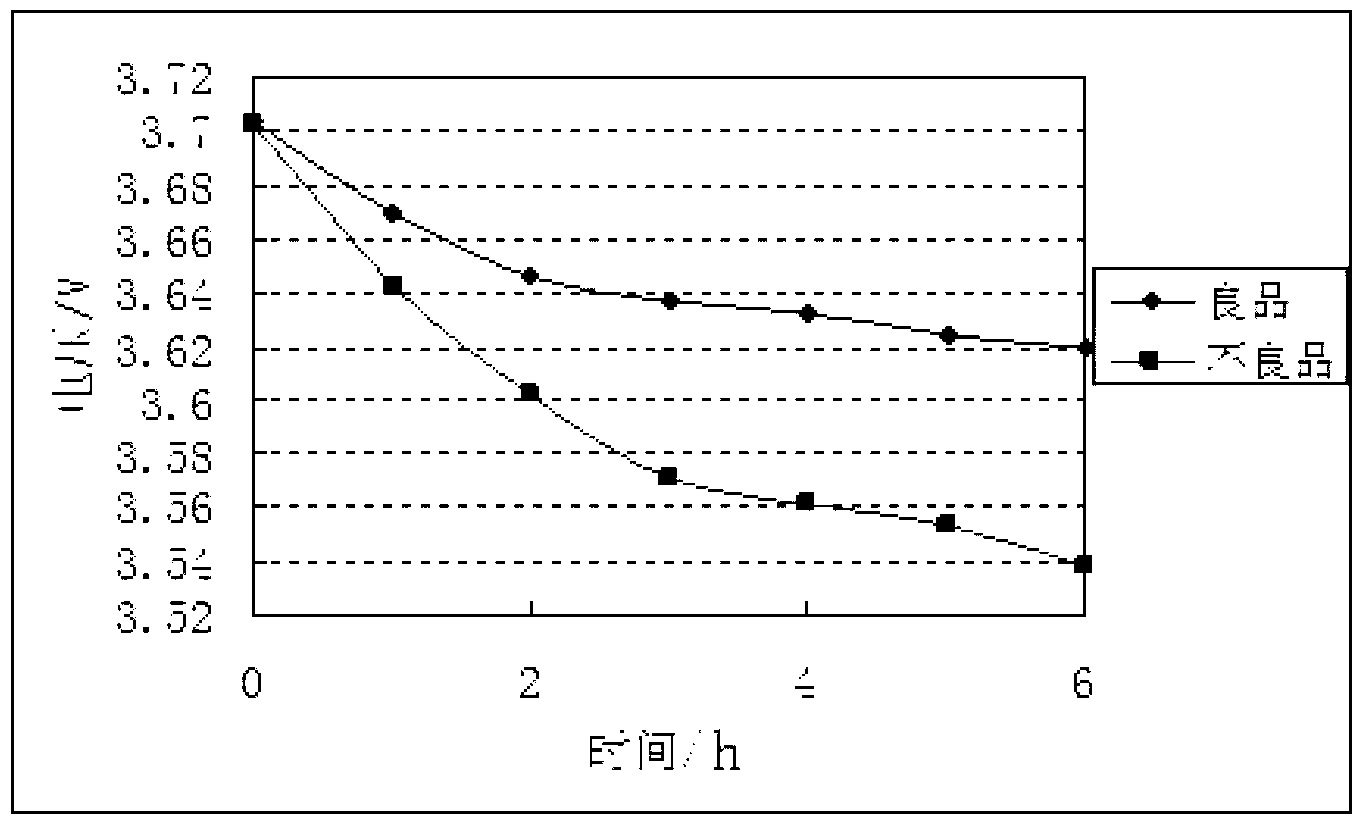

[0018] Example 3: Using lithium cobaltate as the positive electrode material, a polymer 554060P 1500mAh battery cell was made, charged to 3.700V with constant current and constant voltage, aged at 45.0°C for 6 hours, and the voltage of the battery was tested. The voltage trend is as follows: image 3 As shown, there is a voltage difference of 0.08V between the good product and the defective product after the battery is aged for 6 hours, and the defective product can be accurately picked out by measuring the voltage. Compared with Example 1, it shows that within a limited temperature range and other conditions are the same, the higher the aging temperature, the easier it is to distinguish defective products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com