Crack propagation signal calibration device and method based on DCPD method

A technology for crack growth and calibration devices, which is applied in the field of calibration devices based on DCPD crack growth signals, can solve the problems of not obtaining stable performance, repeated use of crack growth signals, slow crack growth rate, and unsuitable signal sources, etc., to achieve saving Experimental research costs, speeding up the R&D cycle, and solving destructive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

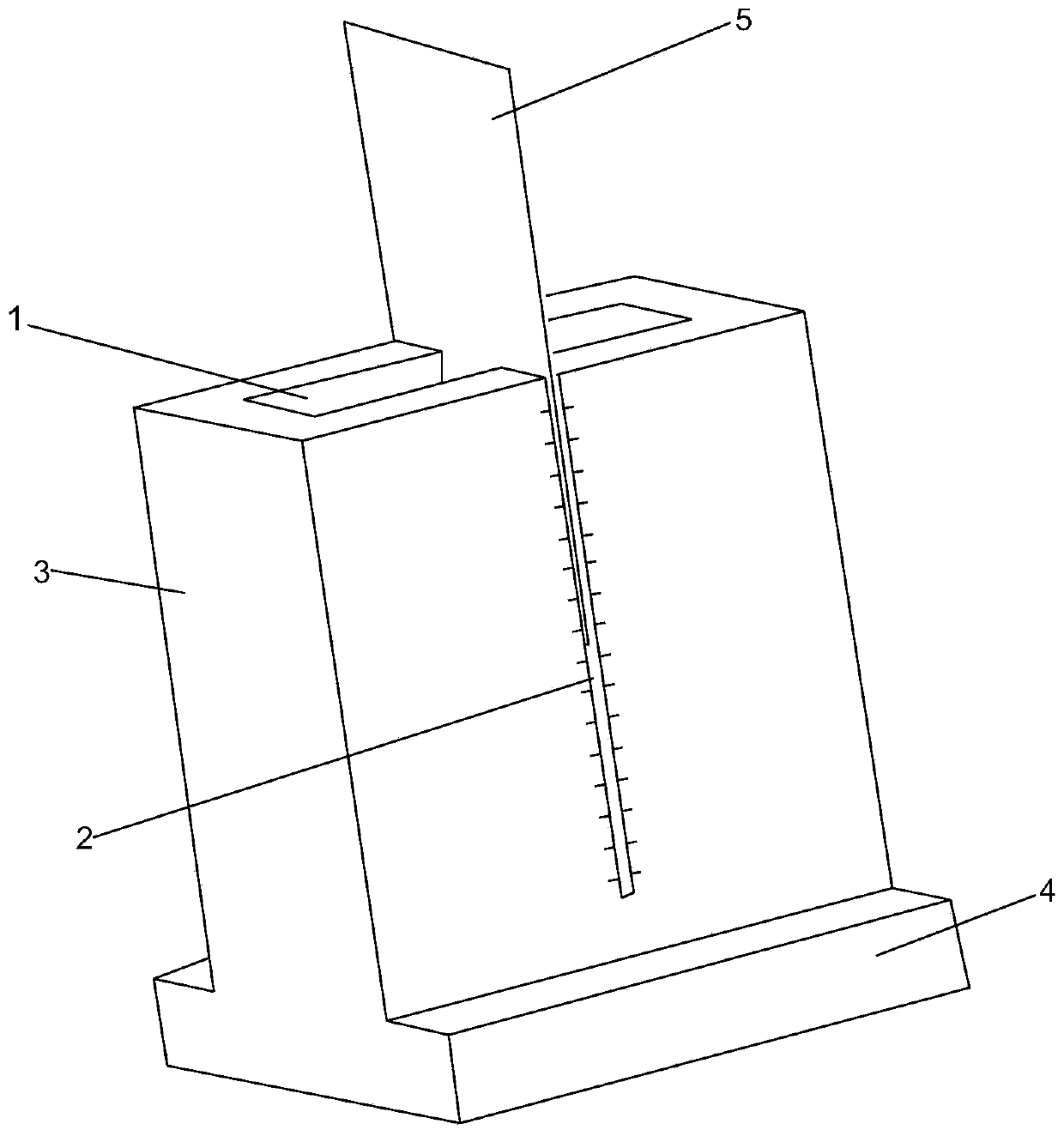

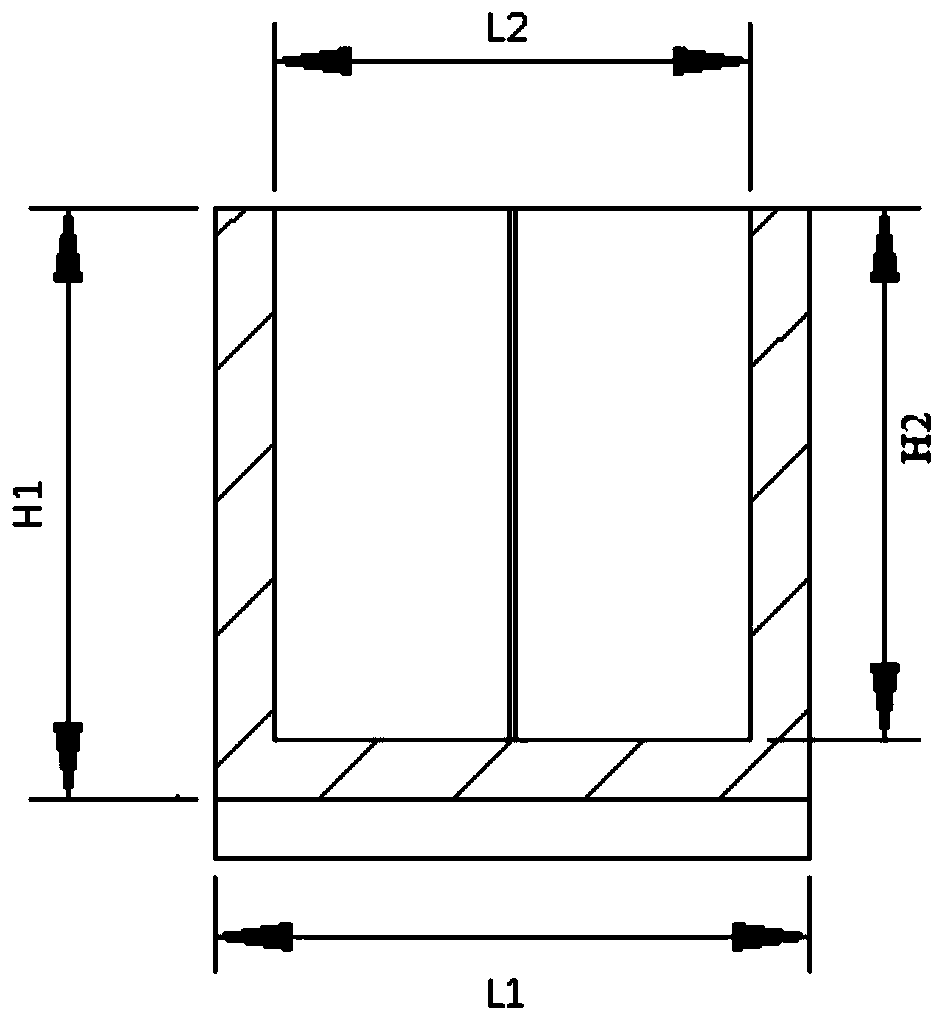

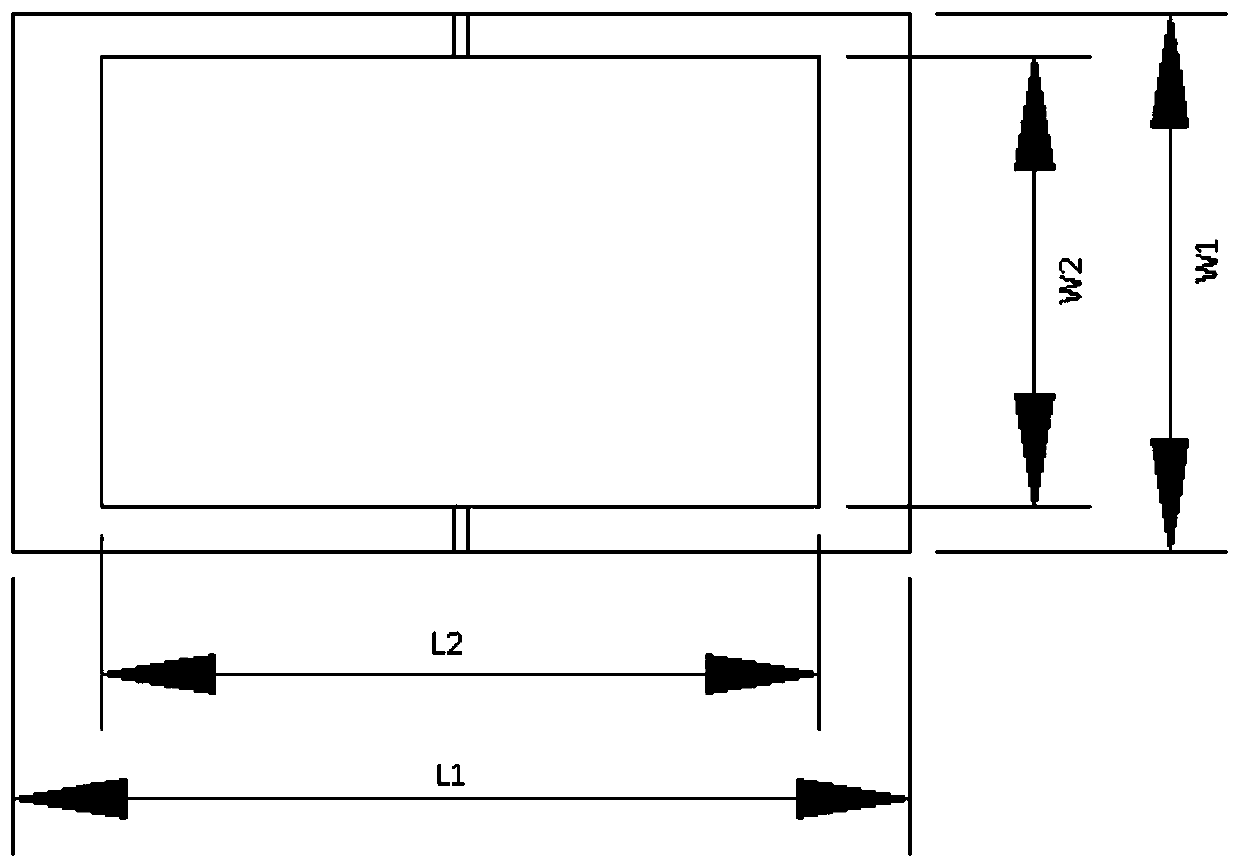

[0041]The principle of DCPD applied in the crack monitoring instrument based on the DCPD (direct current potential drop) method is: the potential drop method is a method for measuring the crack length based on the electrical conductivity of the metal material itself. like Figure 5 and Figure 6 As shown, on a cracked sample, the current field is a function of the sample geometry, especially the crack size. When a constant current is passed through the sample, the potential will increase with the increase of the crack length in the sample. The potential drop method is generally implemented by the four-probe method, the outer two probes (C1, C2) are current electrodes, the excitation current I passes through the tested sample from the outer two probes, and the inner two probes (P1, P2) are the voltage V (Potential difference) Electrode, the potential difference depends on the distribution of current in the sample.

[0042] In order to determine the relationship between the vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com