Automatic generating method for internal compressing boss of plane component

A technology of aircraft structural parts and bosses, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as difficulty in ensuring accuracy, complexity, and low efficiency, and achieve high accuracy, good results, and speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

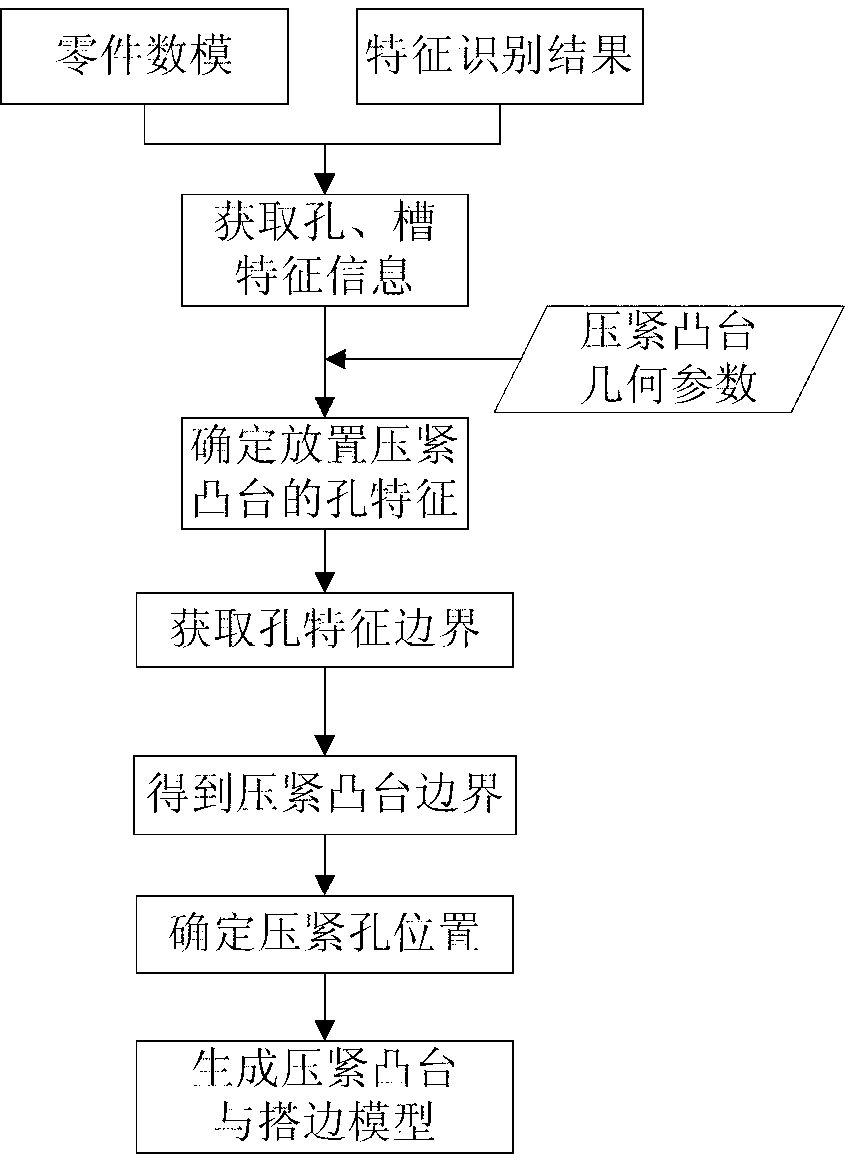

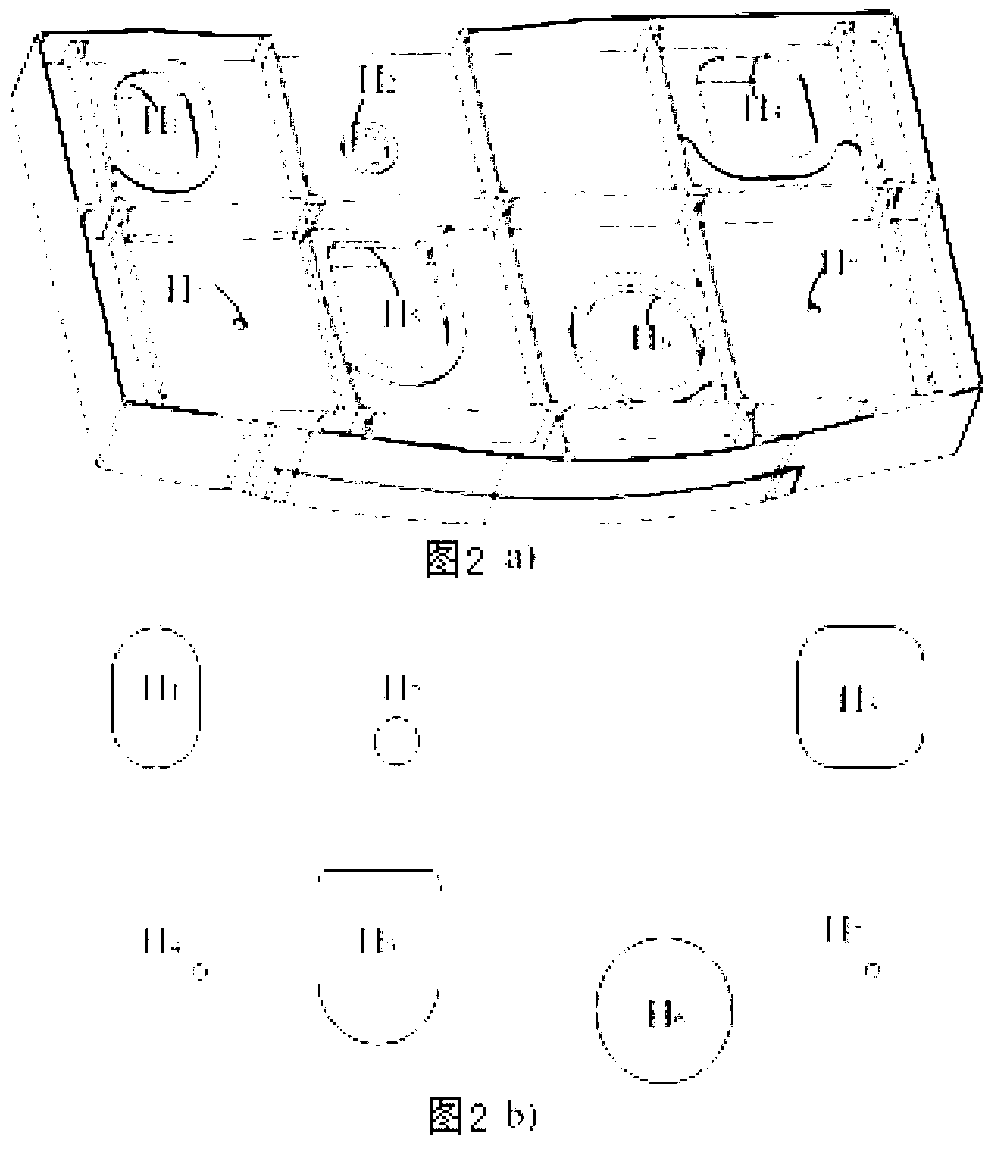

[0065] A method for automatically generating internal compression bosses of aircraft structural parts, the flow chart of which is shown in figure 1 As shown, the example part is as figure 2 shown, including the following steps:

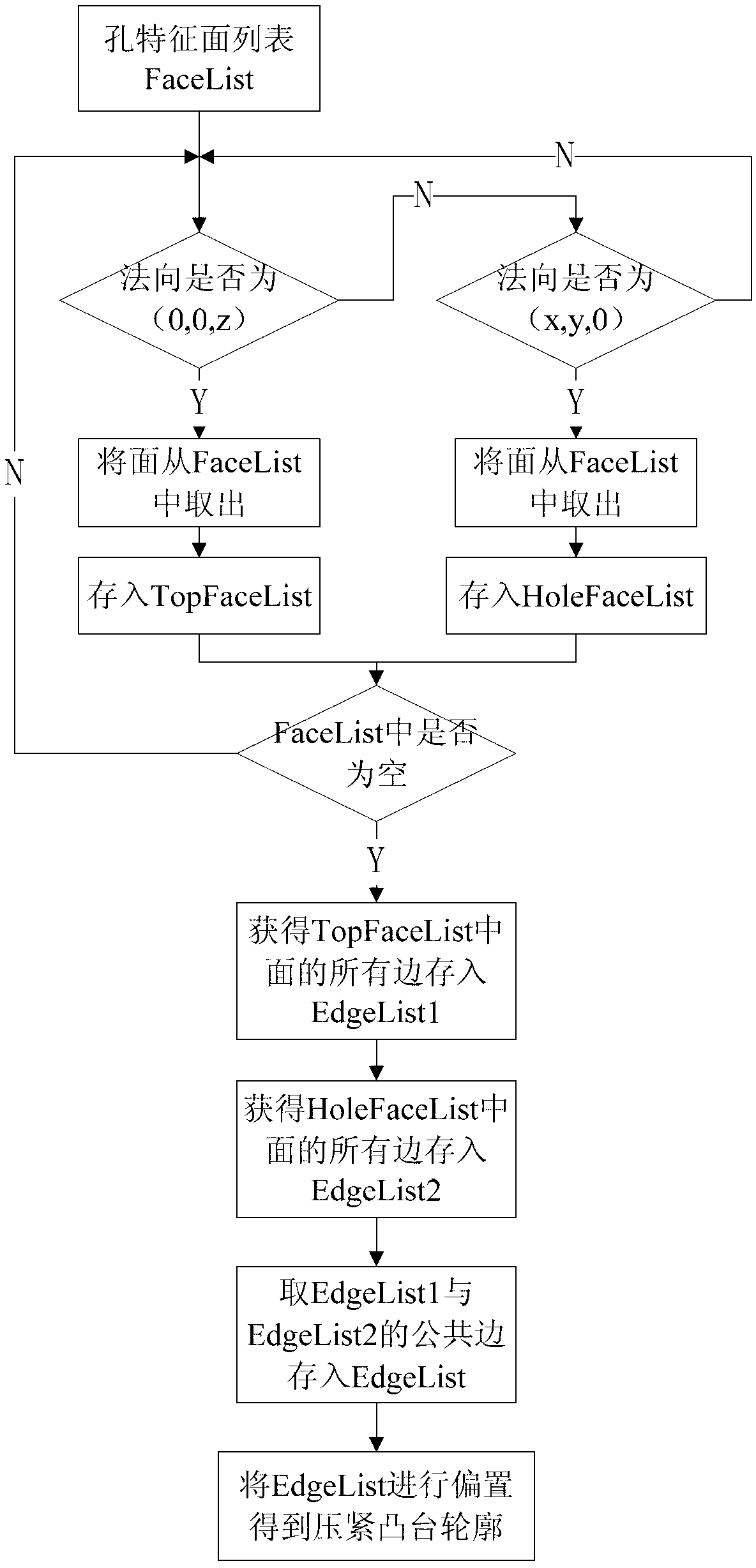

[0066] First, click on the aircraft structural part that needs to be added with an internal pressing boss, and read the feature recognition result information of the aircraft structural part. The information of the hole features and groove features of the part is obtained through the feature recognition results, and the size parameter information of the internal pressing boss is obtained through the human-computer interaction interface. Use automatic and manual methods to determine the hole features that need to be placed on the pressing boss, extract the boundary of the hole feature, and offset the boundary to obtain the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com