Laser pumping device

A technology of laser pumping and pumping light, which is applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of not reaching the state of the laser, not being able to match well, reducing the injection of pumping light, etc., to achieve improved Effect of power injection and homogenization, optimized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended purpose, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0038] In a solid-state laser using a laser crystal with polarization-absorbing properties, in order to effectively utilize the pump light, the embodiment of the present invention makes a detailed design of the laser pump device that emits the pump light.

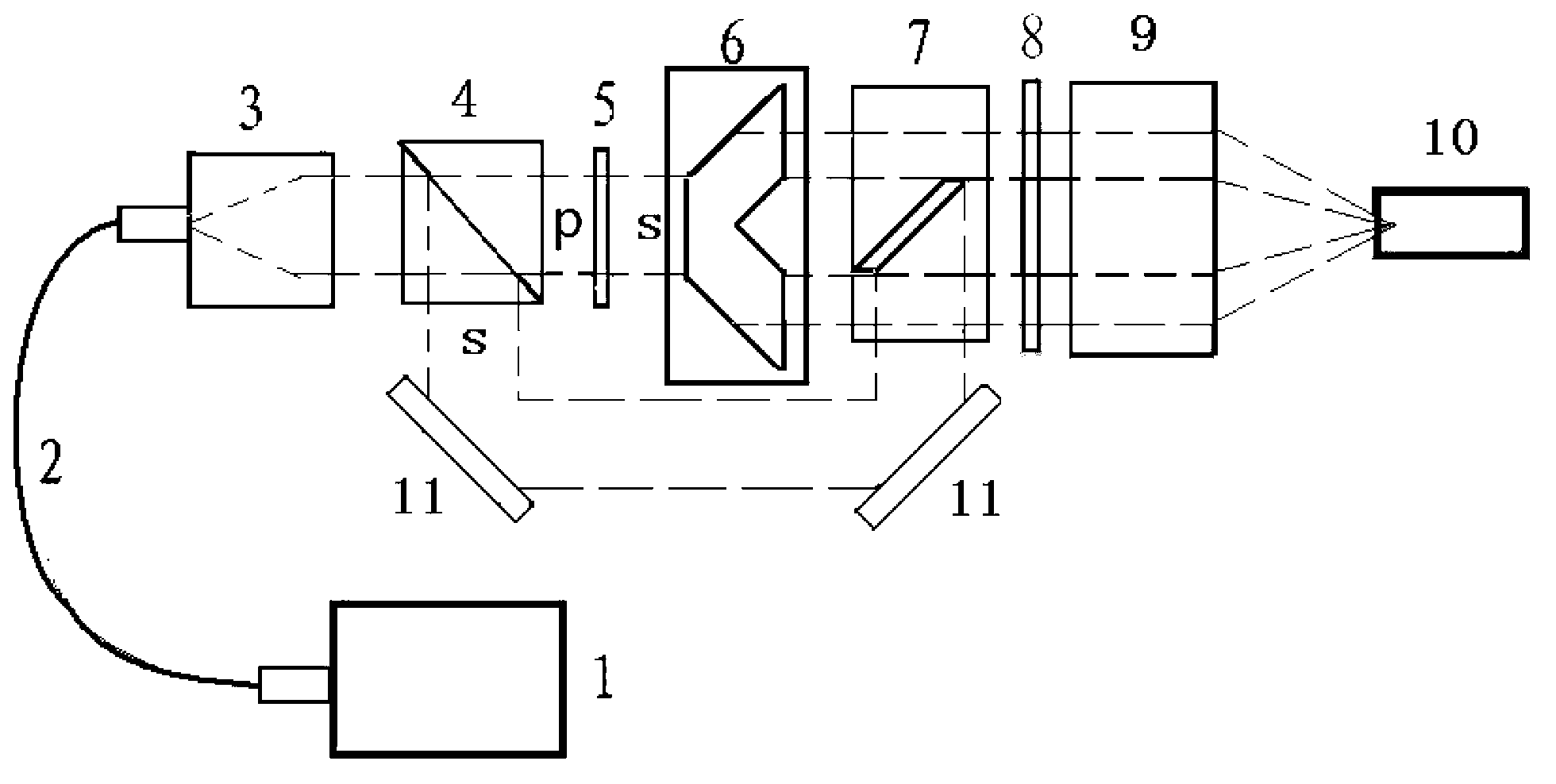

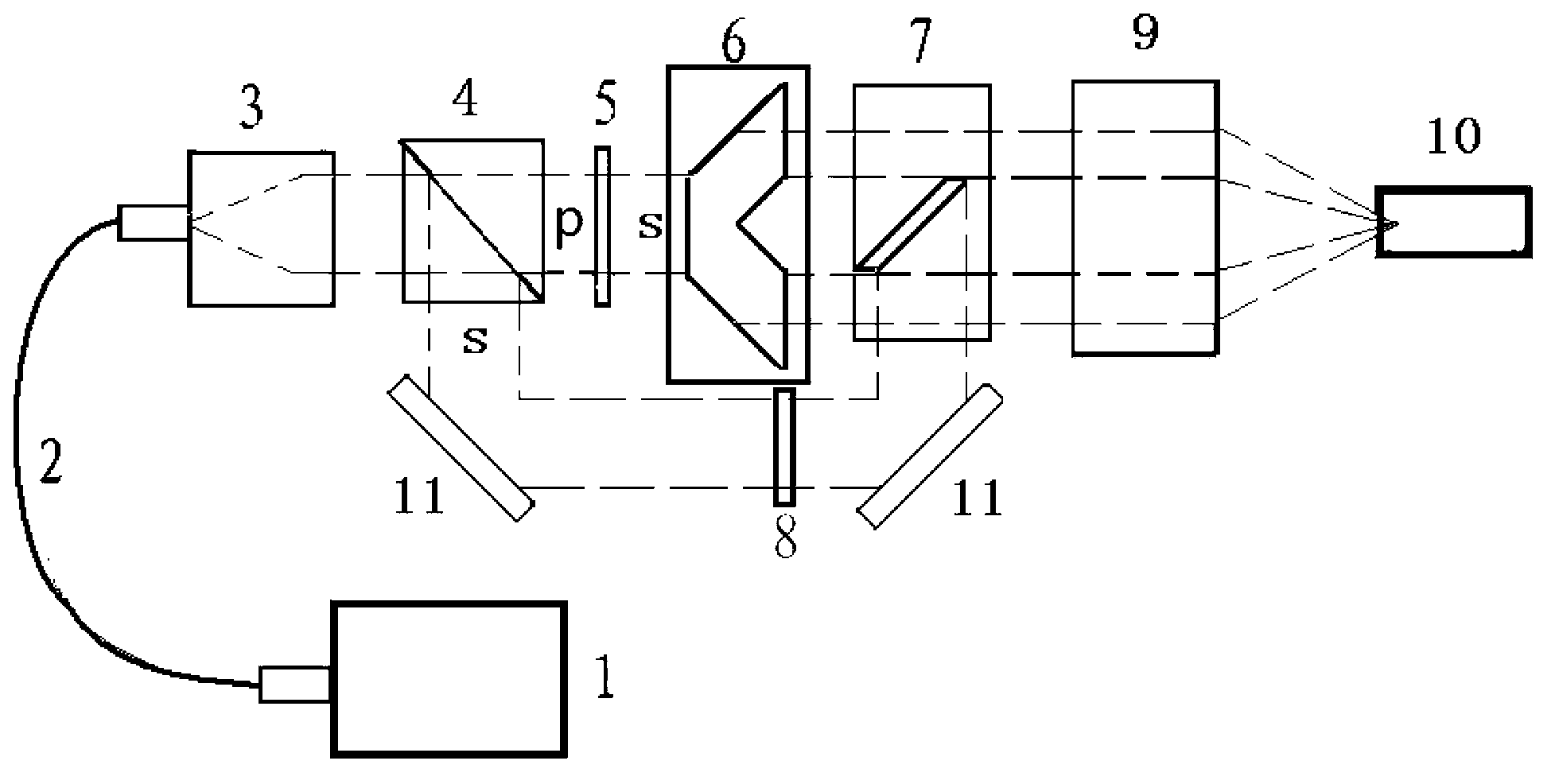

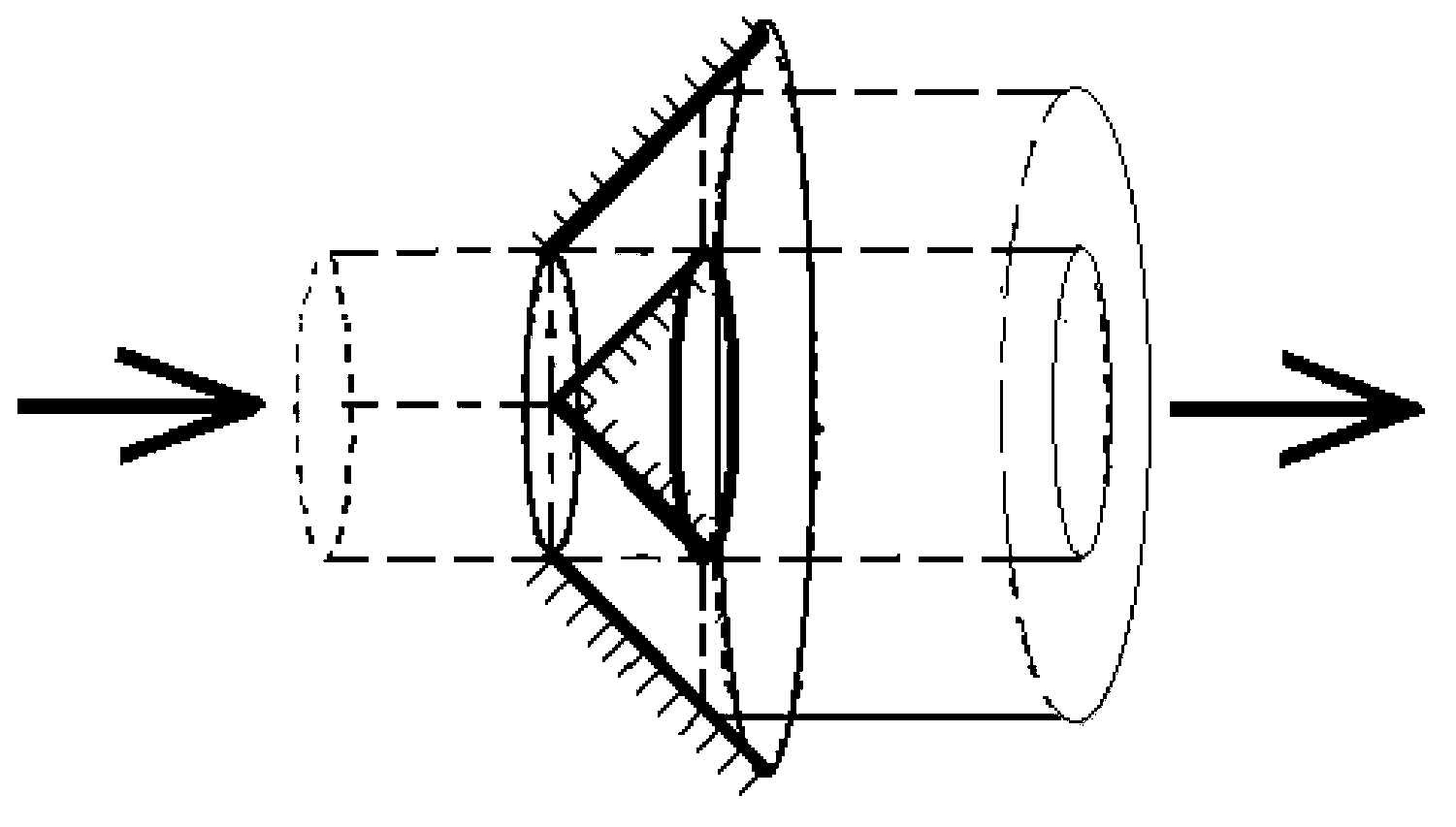

[0039] The laser pumping device of the embodiment of the present invention, such as figure 1 As shown, it includes: a pump light source module 1, a transmission module 2, a collimation module 3, a polarization separation module 4, a polarization direction adjustment module, a beam deformation module 6, a beam combination module 7 and a convergence module 9, wherein:

[0040] The pump light generated by the pump light source module 1 is transmitted to the colli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com