Magnetic-reaction brushless permanent magnet direct current motor

A DC motor, brushless permanent magnet technology, applied in the direction of electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of small practical range, general effect, easy to burn, etc., to achieve enhanced safety, enhanced efficiency, Enhance the effect of driven couples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

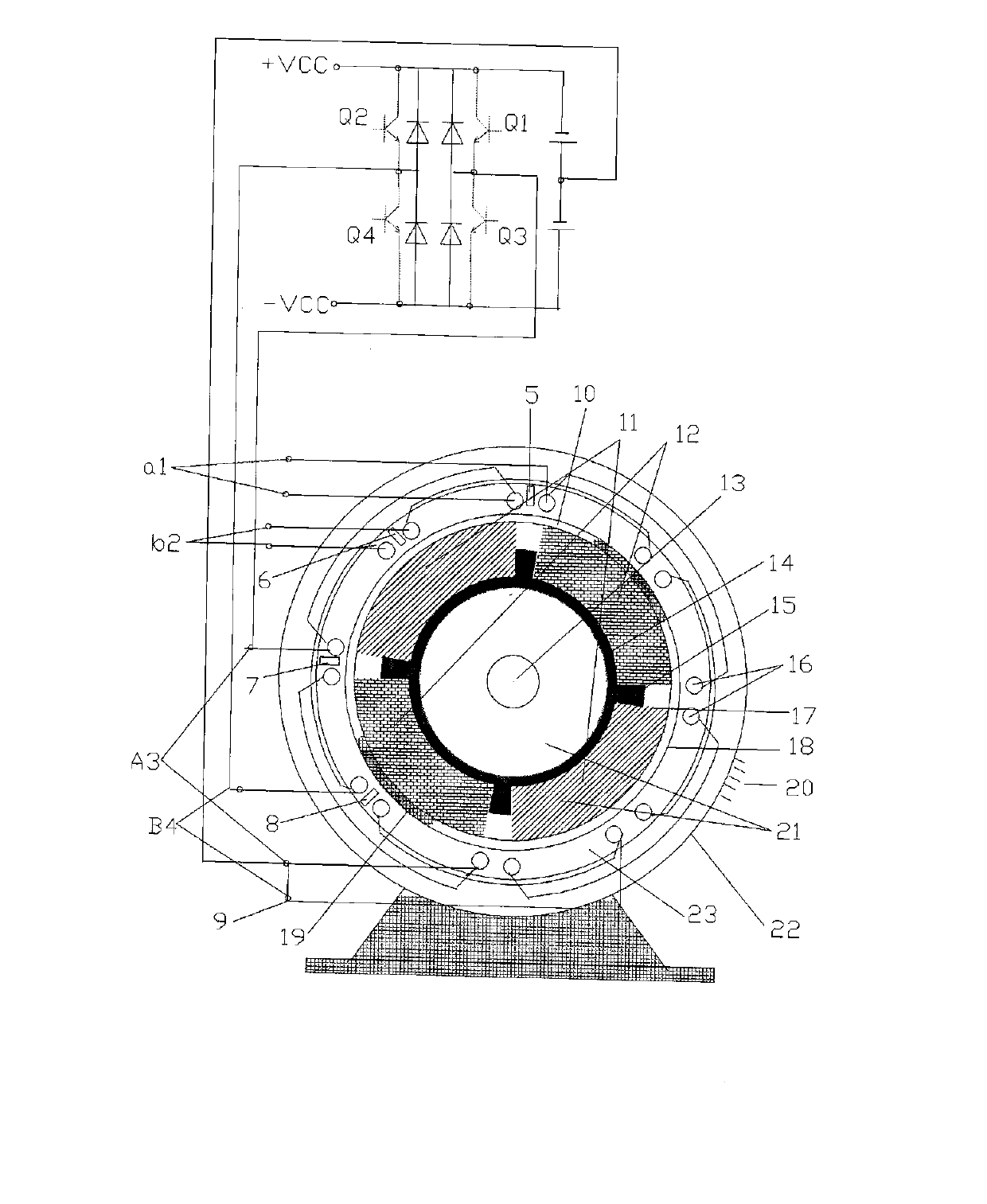

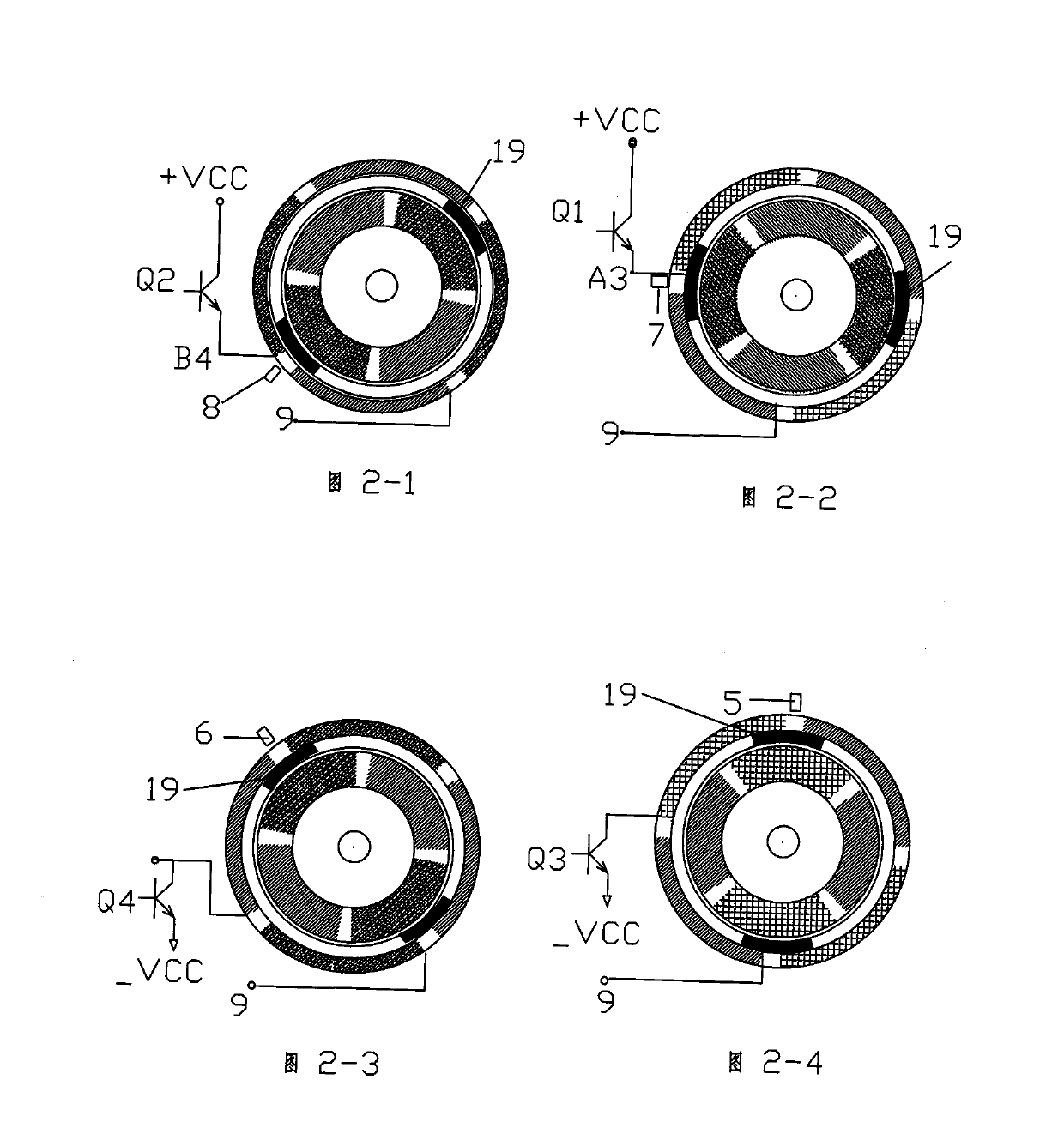

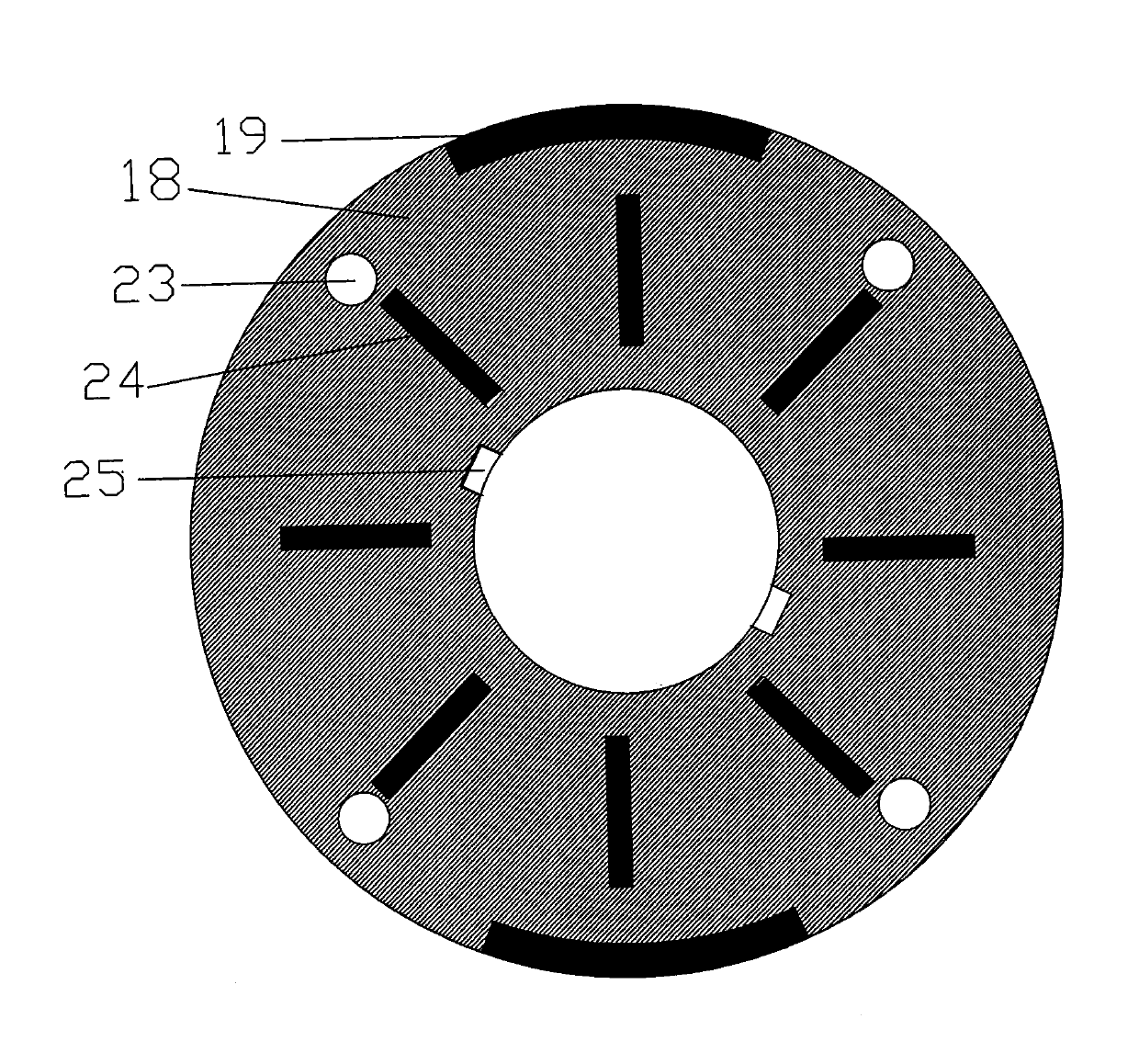

[0029] Magnetic reaction permanent magnet brushless DC motor, taking a four-pole motor with a central shaft drive structure as an example; the stator structure includes a casing 22, a stator core 23, and cooling fins 20; two electromagnetic output windings A3 and B4, two a1, b2 small detection coil; magnetically shielded annular iron bracket 10, position magnetic identification devices 5, 6, 7, 8; permanent magnet rotor device 21 includes permanent magnets 11, 12, central shaft 13, rotor steel cylinder skeleton 14, and magnetic block positioning grid Bone 15; counterweight plate 18, indicating rotor magnetic protruding part 19, fastening screw hole 23, centrifugal fan blade 24, positioning pin groove 25; permanent magnet magnetic field line binding shielding sleeve 17, bearings and other components; dual power supply mode is adopted, Double bridge drive;

[0030] The principle of operation is now taking a motor driven by a four-pole central shaft and using a proximity switch a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com