Solar cell module

A technology of solar cells and light-receiving surfaces, applied in the directions of solar thermal power generation, solar thermal energy, solar thermal collectors, etc., can solve the problems of enlarged area and damage of solar cell modules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

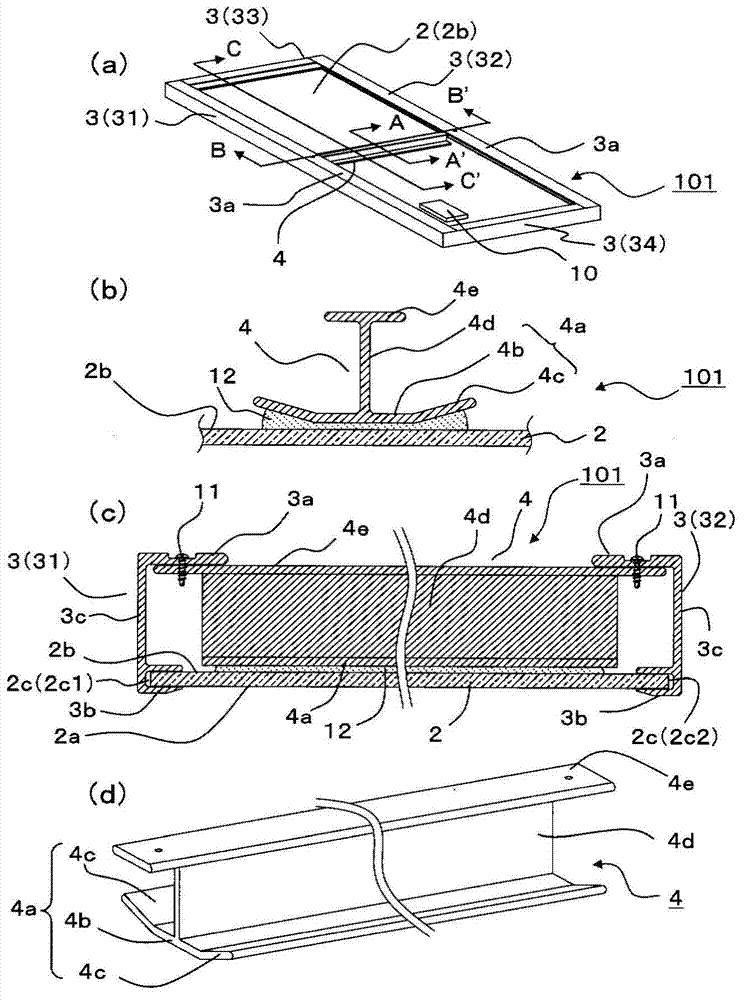

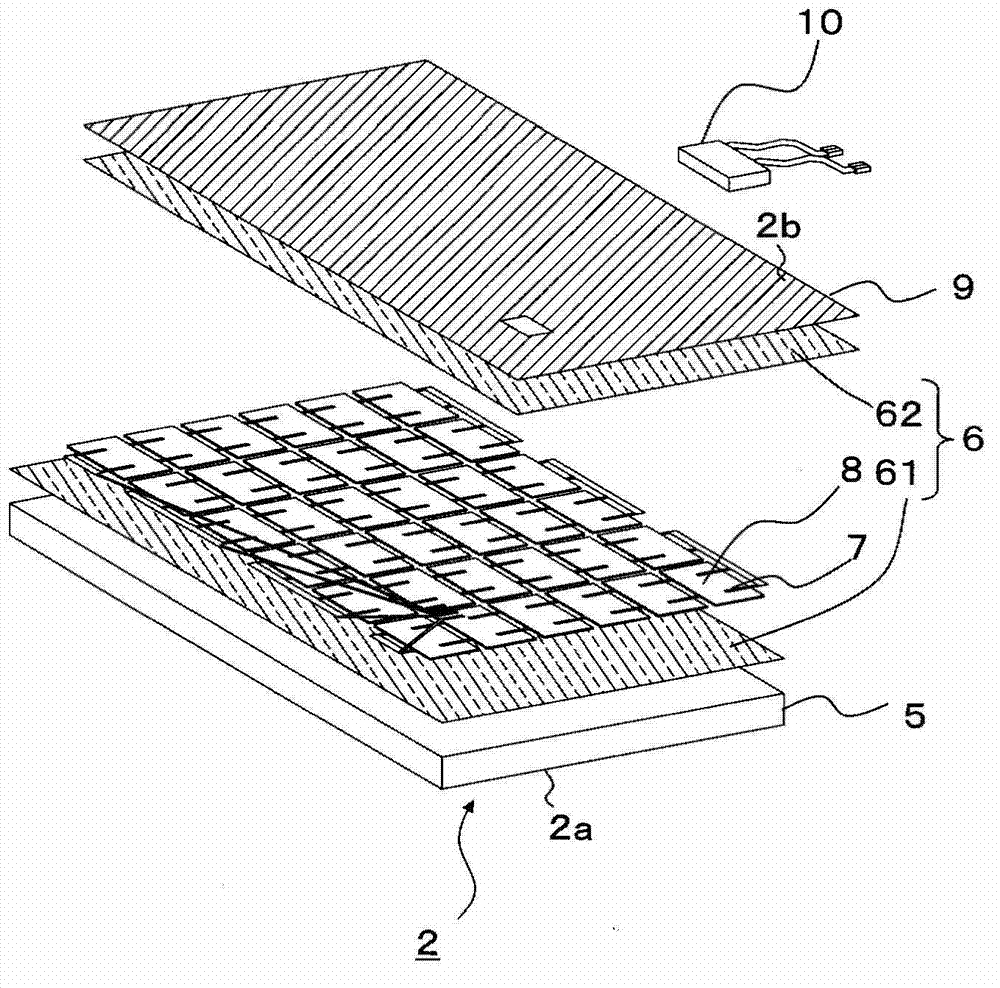

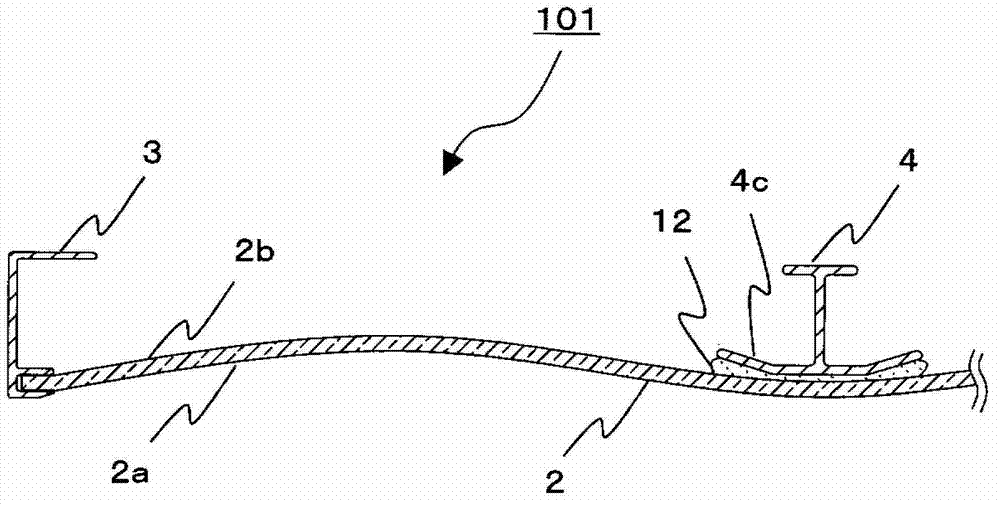

[0028] refer to Figure 1~3 The solar cell module 101 according to the first embodiment will be described.

[0029] Such as figure 1 As shown in (a) and (c), the solar cell module 101 is basically a module including, for example, a rectangular solar cell panel 2 in plan view, a holding member 3 for holding the peripheral portion of the solar cell panel 2 , and a reinforcing member 3 . The holding member 3 includes, for example, a first holding member 31 for holding a pair of side portions 2c (first side portion 2c1, second side portion 2c2) of the solar cell panel 2 substantially parallel to each other, a second holding member 32, and a solar cell panel holding member. The third holding member 33 and the fourth holding member 34 of the other pair of side portions of the 2 are substantially parallel to each other. It should be noted that the solar cell module 101 may also have a terminal box 10 for taking out the output of the solar cell panel 2 on the non-light-receiving sur...

no. 2 approach

[0059] Below, refer to Figure 5 The solar cell module 102 according to the second embodiment of the present invention will be described.

[0060] In the solar cell module 102 according to this embodiment, the shape of the reinforcement member 4 is different from that of the solar cell module 101 according to the first embodiment. Specifically, as Figure 5 As shown, the reinforcing member 4 further has a connecting portion 4f connecting the horizontal portion 4b and the inclined portion 4c. Moreover, the thickness of this connection part 4f is smaller than the thickness of the horizontal part 4b, and it is also smaller than the thickness of the inclined part 4c. That is, the reinforcing member 4 is different from the first embodiment in that the connecting portion between the horizontal portion 4b and the inclined portion 4c is thin and easily bendable.

[0061] This way, for example Figure 5 As shown, it is only necessary to form a notch on the non-light-receiving surfa...

no. 3 approach

[0066] Below, refer to Figure 6 The solar cell module 103 according to the third embodiment of the present invention will be described. The solar cell module 103 according to this embodiment differs from the first embodiment in the shape of the reinforcing member 4 .

[0067] Specifically, as Figure 6 As shown, in the solar cell module 103 according to this embodiment, the thickness of the inclined portion 4c is smaller than the thickness of the horizontal portion 4b. It should be noted that, similarly to the second embodiment, it can also be said that the connecting portion between the horizontal portion 4b and the inclined portion 4c is thinned. That is, in this embodiment, there is a shape in which the plate thickness of the support part 4a becomes thinner ahead from the connection part of the horizontal part 4b and the inclined part 4c.

[0068] In such an aspect, as in the second embodiment, bending tends to occur at the connection portion between the horizontal port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com