Film-forming agent of flowable seed coating formulation and preparation method thereof

A suspension seed coating and film-forming agent technology, applied in botany equipment and methods, seed coating/seed dressing, biocide, etc., can solve the problem that it is not suitable for seed soaking and germination, and the suspension seed coating formulation is compatible Poor performance, not suitable for large-scale mechanical seed dressing, etc., to achieve the effect of increasing air permeability and biological safety, increasing drug resistance, and not affecting seed germination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

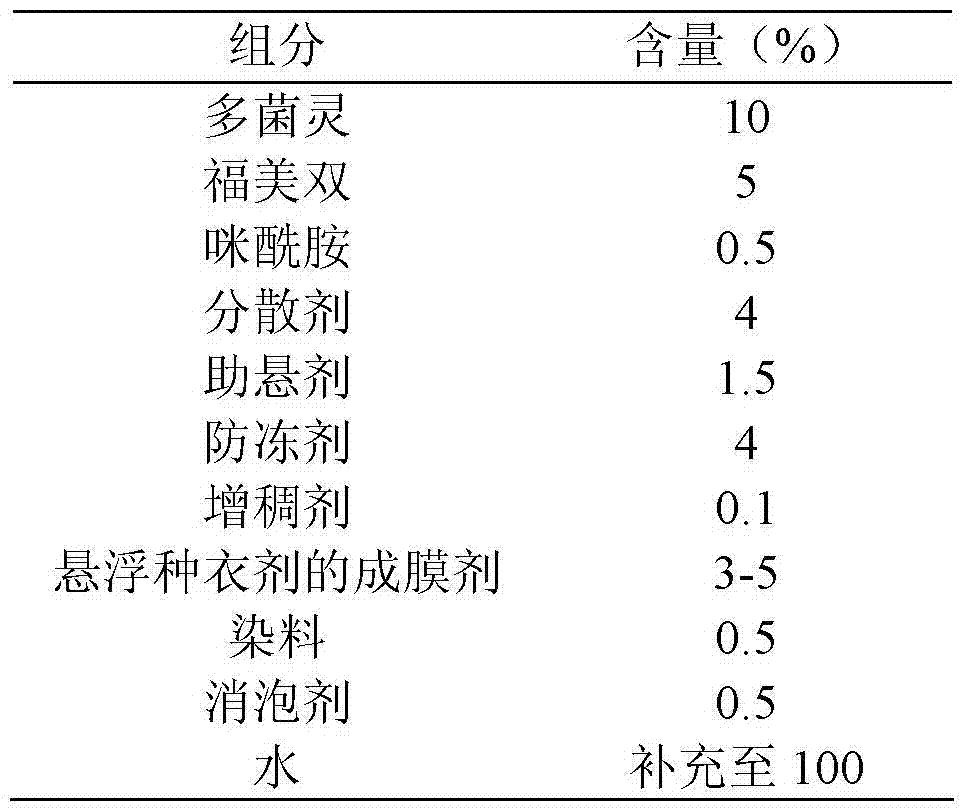

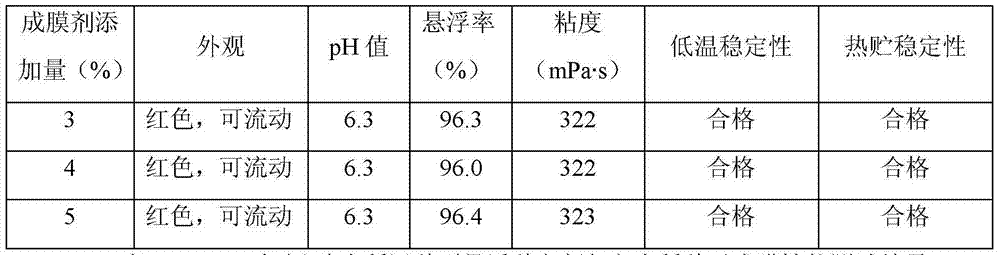

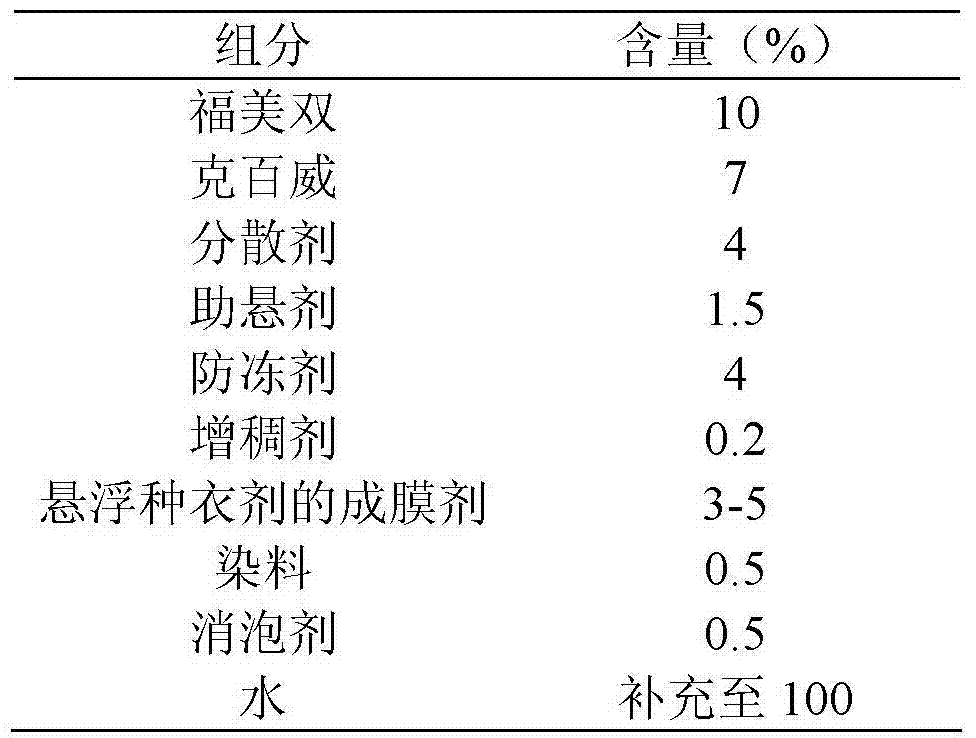

Examples

specific Embodiment approach 1

[0016] Specific embodiment one: the film-forming agent of a kind of suspension seed coating agent of this embodiment, is made up of material A, 100-200 parts of polyvinyl alcohol, 10-30 parts of chlorpyrifos, 180~210 parts of styrene , 180-210 parts of butyl acrylate, 20-30 parts of methyl methacrylate, 20-30 parts of methacrylic acid, 1-3 parts of sodium bicarbonate, 7-9 parts of sodium acrylamido isopropyl sulfonate, 9 ~11 parts of alkyl alcohol polyoxyethylene (3) ammonium sulfate, 25~35 parts of sodium dodecylbenzenesulfonate, 5~7 parts of potassium persulfate, 1~3 parts of N,N'-methylene propylene Amide and 780-810 parts of deionized water; wherein substance A is 20-80 parts of chitosan, 5-25 parts of sodium alginate or 2-10 parts of sodium carboxymethyl cellulose.

[0017] The film-forming agent of this embodiment has water-insoluble properties, the coating film will not be dissolved when soaking seeds, the film-forming time is short, the coating shedding rate is low, an...

specific Embodiment approach 2

[0018] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the film-forming agent of suspension seed coating agent is made of 48 parts of chitosan, 180 parts of polyvinyl alcohol, 12 parts of chlorpyridin, 200 parts by mass. Parts of styrene, 200 parts of butyl acrylate, 25 parts of methyl methacrylate, 25 parts of methacrylic acid, 2 parts of sodium bicarbonate, 8 parts of sodium acrylamidoisopropyl sulfonate, 10 parts of alkyl alcohol polyoxyethylene (3) Made of ammonium sulfate, 30 parts of sodium dodecylbenzenesulfonate, 6 parts of potassium persulfate, 1 part of N,N'-methylene acrylamide and 800 parts of deionized water. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the film-forming agent of the suspended seed coating is composed of 14 parts of sodium alginate, 180 parts of polyvinyl alcohol, and 12 parts of chlorpyridin in parts by mass. , 200 parts of styrene, 200 parts of butyl acrylate, 25 parts of methyl methacrylate, 25 parts of methacrylic acid, 2 parts of sodium bicarbonate, 8 parts of sodium acrylamido isopropyl sulfonate, 10 parts of polyalkylene alcohol Made from oxyethylene(3) ammonium sulfate, 30 parts sodium dodecylbenzenesulfonate, 6 parts potassium persulfate, 1 part N,N'-methylene acrylamide, and 800 parts deionized water. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com