Water-insoluble temperature and pH double-sensitive microgel and preparation method thereof

A water-insoluble, micro-gel technology, applied in the field of daily chemical industry, can solve problems such as limitations, and achieve a wide range and efficient control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

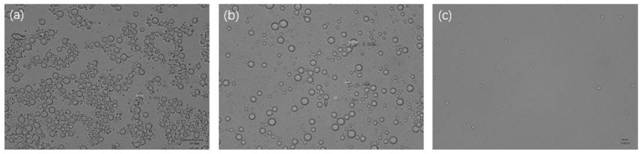

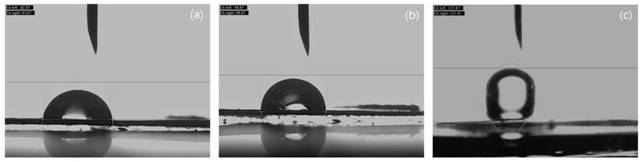

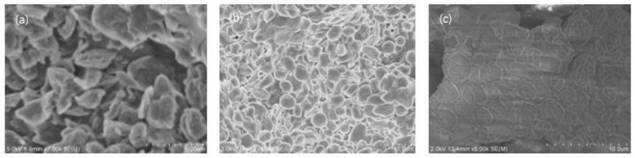

[0041] (1) The temperature-sensitive hydrogel monomer N-isopropylacrylamide with a mass fraction of 10%, the mass fraction of 5% pH-sensitive hydrogel monomer dimethylaminoethyl methacrylate, the mass fraction 2% of the cross-linking agent N,N-methylenebisacrylic acid amine was placed in deionized water and vortexed until it was completely dissolved; in order to simulate the entrapment release experiment, a certain amount of dyeing agent was also added in this example, Specifically, add methylene blue dye with a mass fraction of 5%, and then vortex until completely dissolved;

[0042] (2) placing ethyl cellulose with a mass fraction of 0.5% in the oil phase of 2-n-octyl-1-dodecanol, heating and stirring until completely dissolved;

[0043] (3) The initiator azobisisobutylamidine hydrochloride with a mass fraction of 0.5% is placed in deionized water, and vortexed until completely dissolved;

[0044] (4) Nitrogen is passed into the oil phase solvent gained in step (2), to get ...

Embodiment 2

[0050] (1) The temperature-sensitive hydrogel monomer N-isopropylacrylamide with a mass fraction of 10%, the mass fraction of 5% pH-sensitive hydrogel monomer dimethylaminoethyl methacrylate, the mass fraction 2% of the cross-linking agent N,N-methylenebisacrylic acid amine was placed in deionized water and vortexed until it was completely dissolved; in order to simulate the entrapment release experiment, a certain amount of dyeing agent was also added in this example, Specifically, add methylene blue dye with a mass fraction of 5%, and then vortex until completely dissolved;

[0051] (2) placing ethyl cellulose with a mass fraction of 5% in the oil phase of 2-n-octyl-1-dodecanol, heating and stirring until completely dissolved;

[0052] (3) The initiator azobisisobutylamidine hydrochloride with a mass fraction of 0.5% is placed in deionized water, and vortexed until completely dissolved;

[0053] (4) Nitrogen is passed into the oil phase solvent gained in step (2), to get ri...

Embodiment 3

[0063] (1) The temperature-sensitive hydrogel monomer N-isopropylacrylamide with a mass fraction of 10%, the mass fraction of 5% pH-sensitive hydrogel monomer dimethylaminoethyl methacrylate, the mass fraction 2% of the cross-linking agent N,N-methylenebisacrylic acid amine was placed in deionized water and vortexed until it was completely dissolved; in order to simulate the entrapment release experiment, a certain amount of dyeing agent was also added in this example, Specifically, add methylene blue dye with a mass fraction of 5%, and then vortex until completely dissolved;

[0064] (2) placing ethyl cellulose with a mass fraction of 10% in the oil phase of 2-n-octyl-1-dodecanol, heating and stirring until completely dissolved;

[0065] (3) The initiator azobisisobutylamidine hydrochloride with a mass fraction of 0.5% is placed in deionized water, and vortexed until completely dissolved;

[0066] (4) Nitrogen is passed into the oil phase solvent gained in step (2), to get r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com