Venlafaxine hydrochloride long-acting controlled-release pellets and preparation method thereof

A technology of venlafaxine hydrochloride and sustained-release pellets, which is applied to medical preparations containing no active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, and can solve the problems of low bioavailability, complicated preparation process, and Conformity and other issues, to achieve the effect of clear drug effect, mature preparation process, and ensure uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

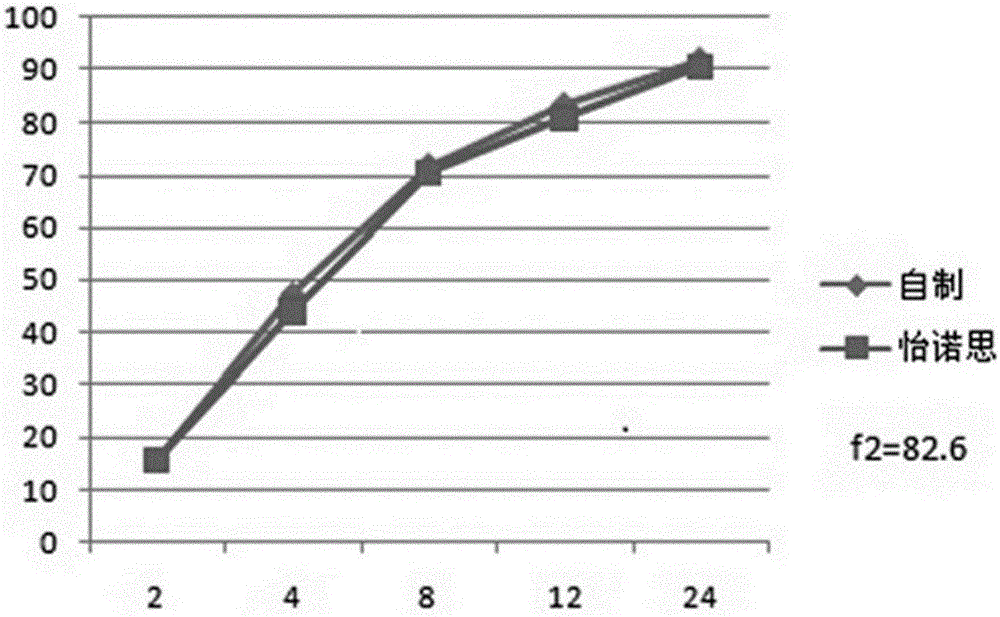

Embodiment 1

[0054] The preparation of embodiment 1 venlafaxine hydrochloride sustained-release pellets

[0055] 1. Prescription of pills: 2000 pills (1000 pills for the first pill and 1000 pills for the second pill)

[0056] material

Prescription volume (g)

Proportion (%)

effect

200

/

Ball core

180

About 90% of the ball core

14.4

About 8% of active ingredients

Antisticking agent

5.4

About 3% of active ingredients

85% ethanol

Appropriate amount

/

[0057] In the above prescription, the particle size of the pellet core is 500-700 μm, of which the pellet core with a particle diameter of 500-600 μm accounts for 50%, and the talcum powder is 3000 mesh.

[0058] 2. Disposal of the first sustained-release pills: based on 1000 pills

[0059] material

...

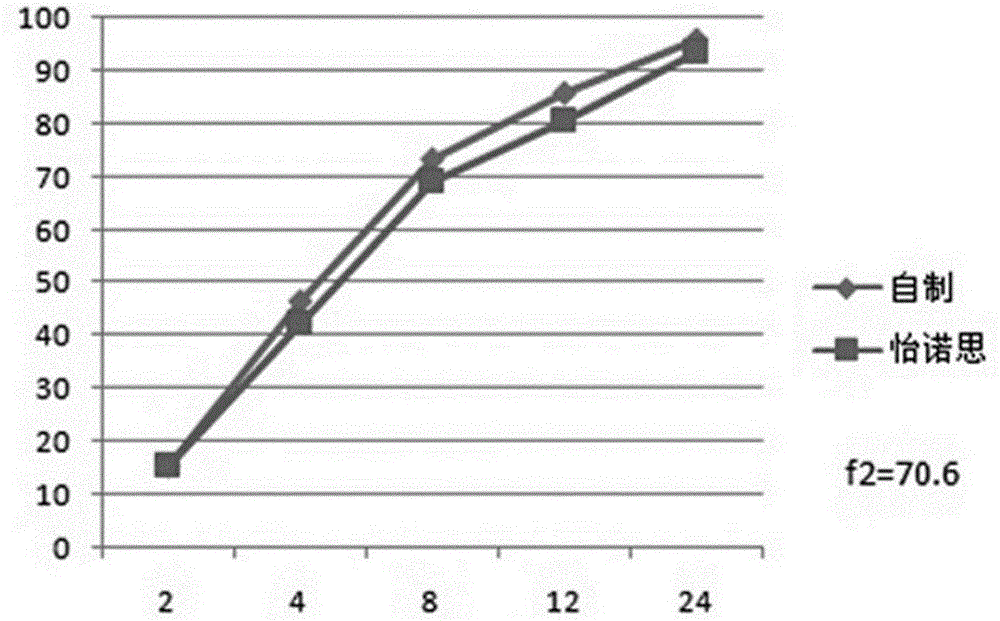

Embodiment 2

[0070] The preparation of embodiment 2 venlafaxine hydrochloride sustained-release pellets

[0071] 1. Prescription of pills: 2000 pills (1000 pills for the first pill and 1000 pills for the second pill)

[0072] material

Prescription volume (g)

Proportion (%)

effect

200

/

Ball core

160

About 80% of the ball core

Talc powder

16

About 10% of the active ingredient

Antisticking agent

8

About 5% of the active ingredient

85% ethanol

Appropriate amount

/

[0073] In the above prescription, the particle size of the pellet core is 500-700 μm, of which the pellet core with a particle diameter of 500-600 μm accounts for 35%, and the talcum powder is 3000 mesh.

[0074] 2. Disposal of the first sustained-release pills: based on 1000 pills

[0075] material ...

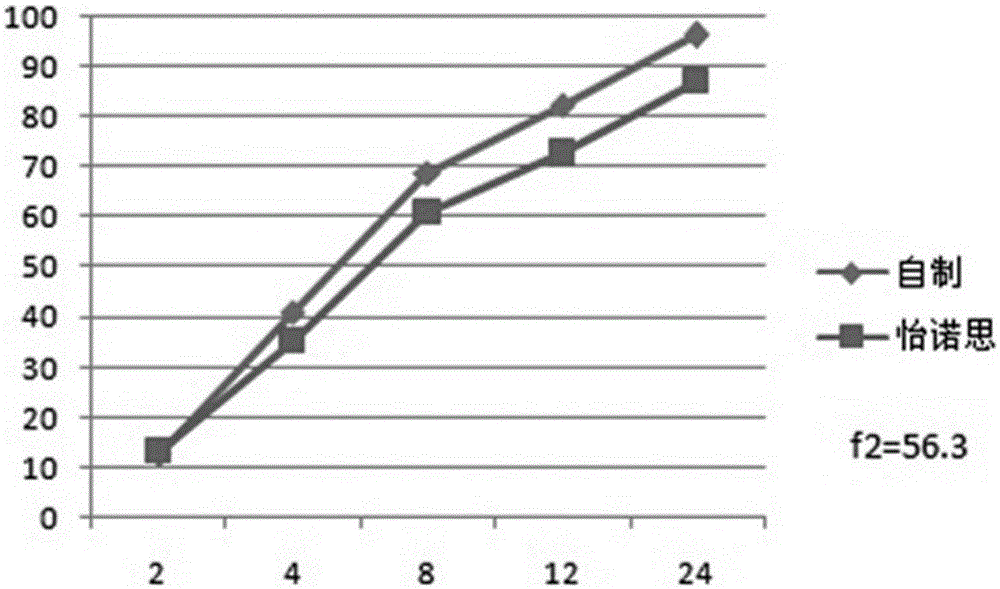

Embodiment 3

[0082] The preparation of embodiment 3 venlafaxine hydrochloride sustained-release pellets

[0083] 1. Prescription of pills: 2000 pills (1000 pills for the first pill and 1000 pills for the second pill)

[0084] material

Prescription volume (g)

Proportion (%)

effect

200

/

Ball core

200

About 100% of the ball core

active ingredient

2

About 1% of active ingredient

85% ethanol

Appropriate amount

/

[0085] In the above prescription, the particle size of the ball core is 500-700 μm, and the ball core with a particle size of 500-600 μm accounts for 65%; the talcum powder is 3000 mesh.

[0086] 2. Disposal of the first sustained-release pills: based on 1000 pills

[0087] material

Prescription volume (g)

Proportion (%)

effect

first pill

195

/

/

Ethyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com