Method for representing organic matter bonding strength in sludge extracellular polymeric substance

A technology of extracellular polymers and binding strength, applied in sludge treatment, water pollutants, chemical instruments and methods, etc., can solve the lack of quantitative description of EPS binding strength, etc., and achieve the effect of easy separation and improved resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

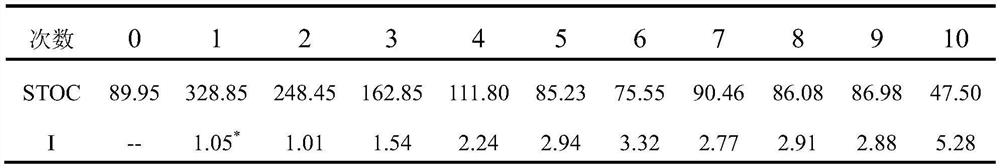

[0037] (1) The concentrations of STOC, TS and VS of secondary sludge were determined to be 89.95 mg / L, 3.10% and 1.41%, respectively.

[0038] (2) Wash the resin for later use. Sodium cation exchange resin (model: 001×7) was washed with ultrapure water until the supernatant was clear and colorless, soaked in 2 times the volume of HCl solution (1mol / L) for 4 hours, and washed with ultrapure water until neutral. Then soak in 2 times the volume of NaOH solution (1mol / L) for 4 hours, then wash with ultrapure water until neutral, and use a vacuum pump to suction filter the washed resin to remove gravity water and interstitial water for later use.

[0039] (3) Determination of the total capacity Q of resin-induced sludge to release extracellular organic matter. Take 300mL of secondary sludge, add pretreated 001×7 resin according to 15g / g VS and stir, the stirring speed is 500rpm, and the reaction temperature is controlled to 20℃. The STOC concentration of the sludge was measured at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com