Cefaclor granule and preparation method thereof

A technology of Clorox granules and cefaclor, which is applied in the field of medicine, can solve problems such as stratification, poor solution suspension effect, and influence on drug efficacy, and achieve the effects of simple preparation process, good water solubility, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

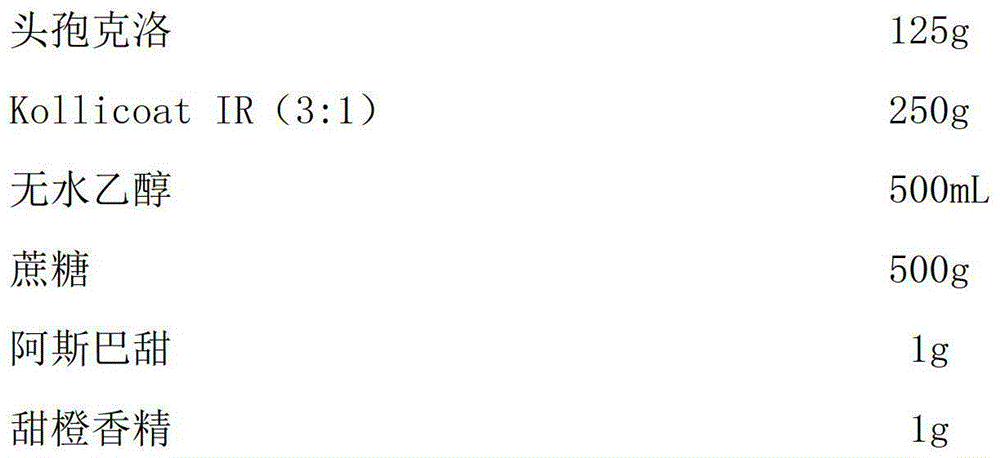

Embodiment 1

[0018]

[0019] Preparation Process:

[0020] Pass cefaclor through a 100 mesh sieve, dissolve Kollicoat IR (3:1) in absolute ethanol, add cefaclor, stir evenly and dry under reduced pressure to remove ethanol, and mix the dried granules with sucrose, albino Spartame and sweet orange essence are mixed evenly and packaged.

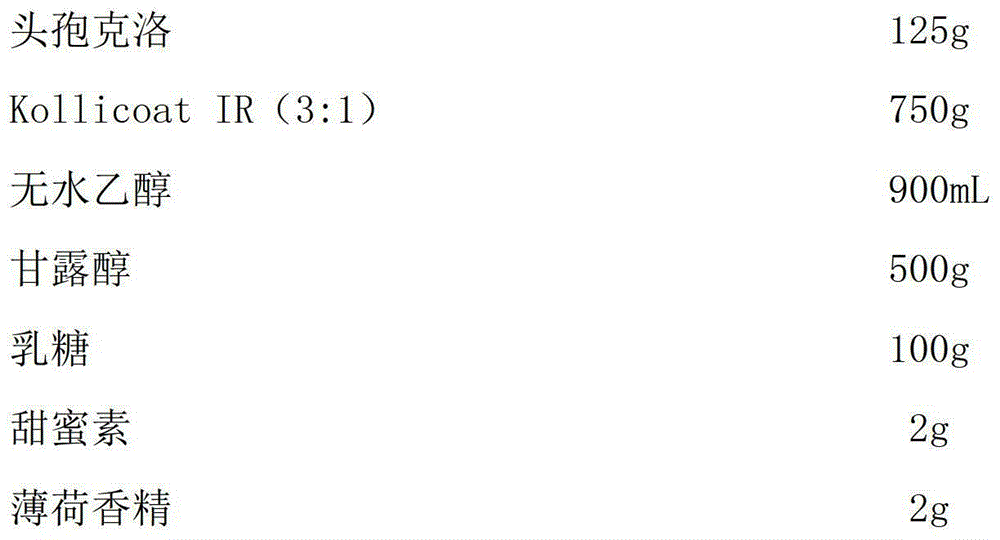

Embodiment 2

[0022]

[0023] Preparation Process:

[0024] Pass cefaclor through a 100 mesh sieve, dissolve Kollicoat IR (3:1) in absolute ethanol, add cefaclor, stir evenly and dry under reduced pressure to remove ethanol, mix the dried granules with mannitol, Lactose, cyclamate, and mint essence are mixed evenly and packaged.

Embodiment 3

[0026]

[0027]

[0028] Preparation Process:

[0029] Pass cefaclor through a 100 mesh sieve, dissolve Kollicoat IR (3:1) in absolute ethanol, add cefaclor, stir evenly and dry under reduced pressure to remove ethanol, mix the dried granules with mannitol, sucrose, aspartame Sweet mix well, pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com