Alligator assembly technology of cylinder bodies for offshore wind power

An offshore wind power, cylindrical body technology, applied in the direction of manufacturing tools, metal processing equipment, auxiliary devices, etc., can solve the problems of time-consuming, labor-intensive, waste of raw materials, etc., and achieve the effect of reducing workload, saving time, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

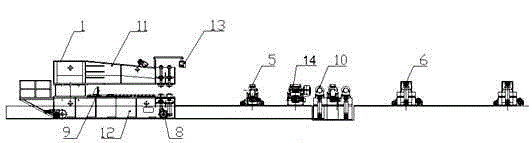

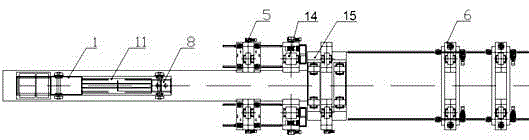

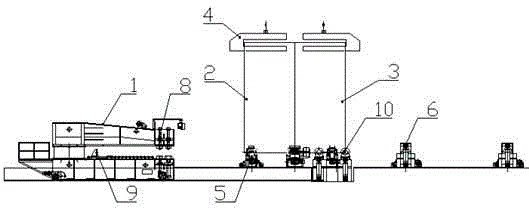

[0018] see Figure 1 to Figure 8 The crocodile-type assembling machine 1 is adopted when the crocodile-type assembling method of the wind power cylinder of the present invention is implemented, and the crocodile-type assembling machine 1 has two important structures of the palate 11 and the lower jaw 12. The mouth is provided with a hydraulic pushing device 9, on the inner side of the positioning hydraulic cylinder group 8 at the front end of the palate 11 and the lower jaw 12, an upper compression cylinder 81 and an upper alignment cylinder 82 are installed, and an upper compression cylinder is installed below. 81 and the following alignment cylinder 83 corresponding to the alignment cylinder 82 and the lower compression cylinder 84, a lower camera and a spotlight 85 are housed between the lower alignment cylinder 83 and the lower compression cylinder 84. The two sides below the crocodile-type assembly machine 1 are equipped with road wheels and driving devices, and the road ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com