Roller product with high performance and high binding power between metal insert and PU tire bead, prepared by injection molding method

A metal and roller technology, applied in the field of polyurethane roller and its injection molding process, can solve the problems of high material cost, high labor cost, low production efficiency, etc., and achieve the effect of improving the bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

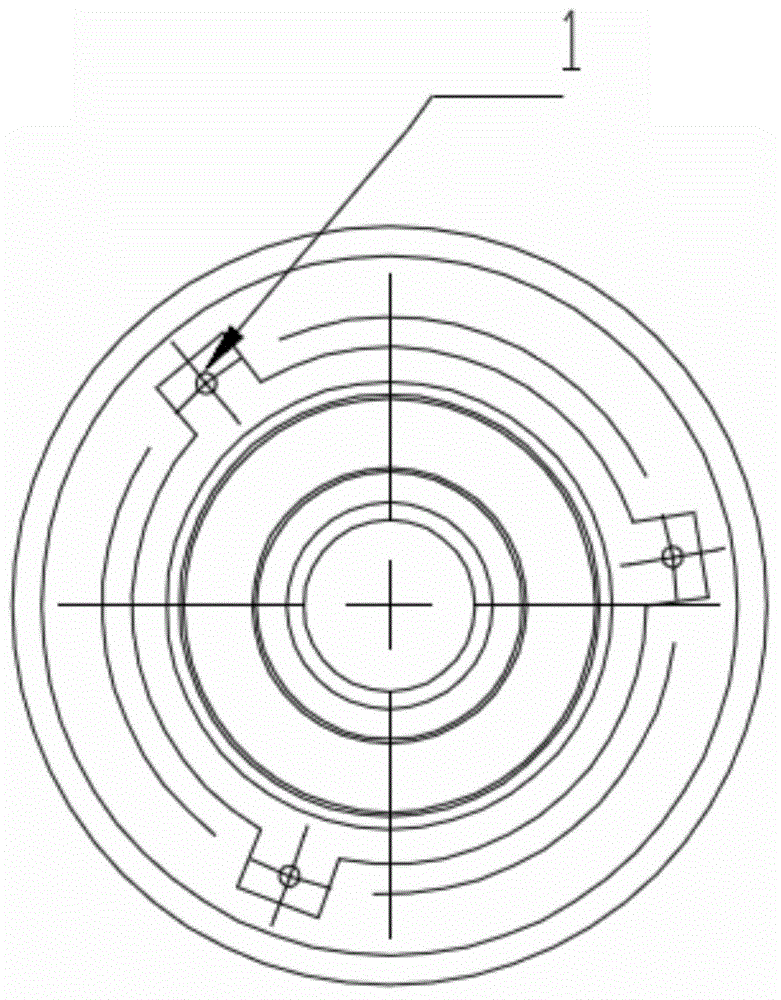

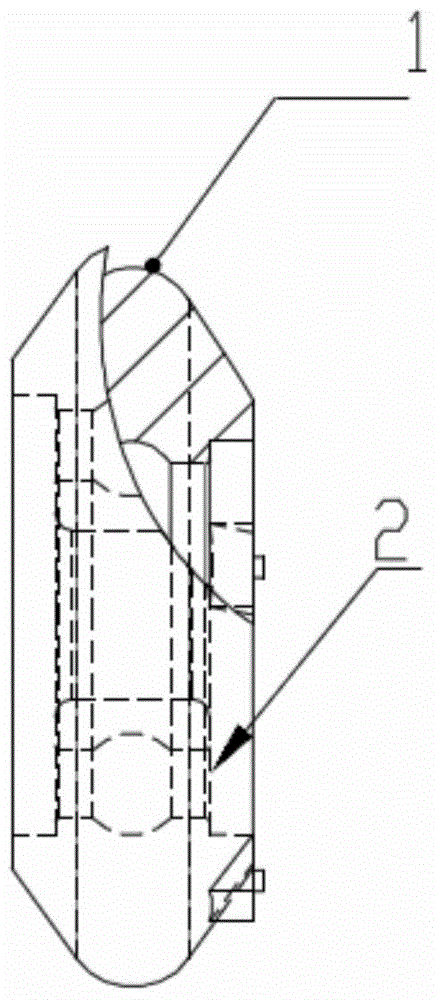

Image

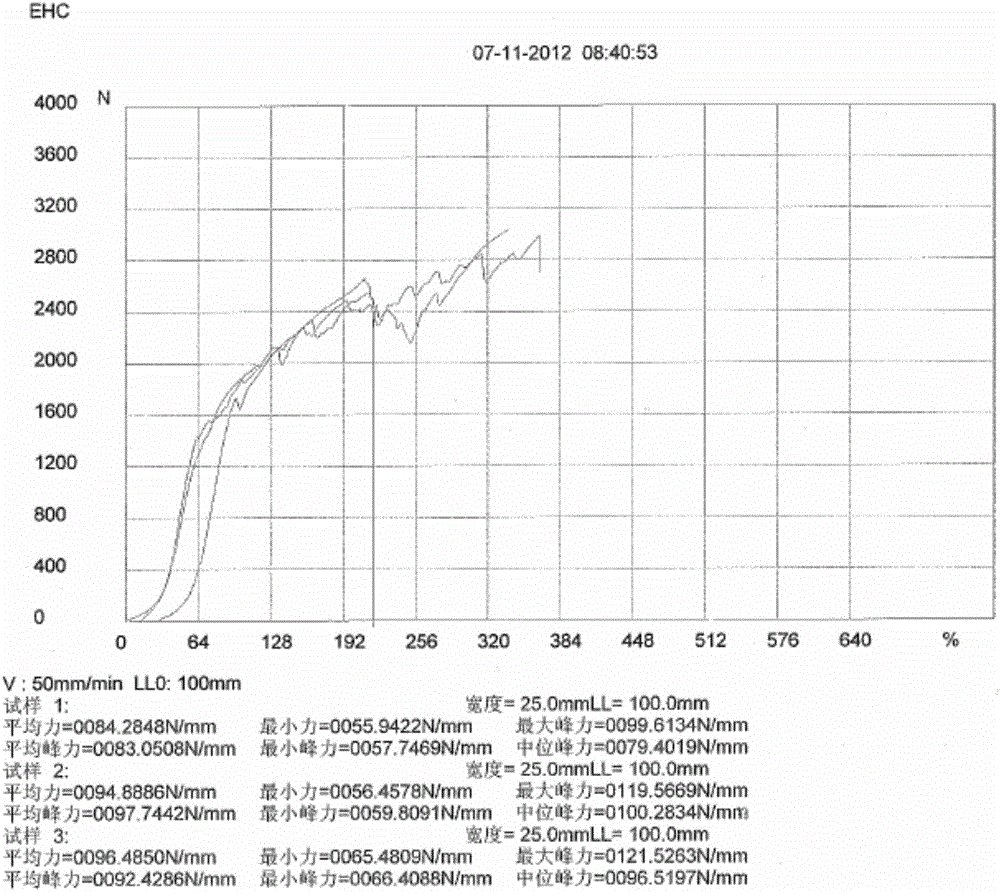

Examples

Embodiment 1

[0066] Prepare polyurethane rollers without bearings, including the following steps:

[0067] 1) Pre-sandblasting and roughening the glue-sprayed surface of the metal hub;

[0068] 2), carry out surface degreasing and cleaning operation to the metal wheel hub that step 1) obtains;

[0069] 3), the glue-spraying surface of the metal wheel hub obtained in step 2) is pre-sprayed with a high-temperature reactive adhesive;

[0070] 4), the pre-sprayed metal hub obtained in step 3) is preliminarily dried for 2-3 hours in an environment of 5-30°C under a humidity of ≤75%;

[0071] 5), preheating the preliminary dried pre-sprayed metal hub obtained in step 4) at 110-120° C. for 2-10 hours;

[0072] 6) Put the metal hub pre-sprayed with adhesive obtained in step 5) into the injection mold cavity for positioning and fixing, then close the mold, and then use a 160-260T low-pressure injection molding machine to inject liquid thermoplastic polyurethane material from the pouring machine s...

Embodiment 2

[0075] Prepare the polyurethane roller of the aluminum alloy wheel hub with bearing, comprise the following steps:

[0076] 1) Pre-blasting and roughening the glue-sprayed surface of the aluminum alloy wheel with quartz sand;

[0077] 2), using an automatic water cleaning machine to carry out surface degreasing and cleaning operations on the metal wheel hub obtained in step 1);

[0078] 3), the glue-spraying surface of the metal wheel hub obtained in step 2) is pre-sprayed with a high-temperature reactive adhesive of British Sibang 49C;

[0079] 4), the pre-sprayed metal wheel hub obtained in step 3) is preliminarily dried for 2-3 hours in an environment of 5-30°C at a humidity of <75%;

[0080] 5), put the preliminary dried pre-sprayed metal hub obtained in step 4) into an oven at 110-120° C., and preheat for 2-10 hours;

[0081] 6) Put the metal hub pre-sprayed with adhesive obtained in step 5) into the injection mold cavity for positioning and fixing, then close the mold,...

Embodiment 3

[0085] Prepare polyurethane rollers without bearings, including the following steps:

[0086] 1) Pre-sandblasting and roughening the glue-sprayed surface of the metal hub;

[0087] 2), carry out surface degreasing and cleaning operation to the metal wheel hub that step 1) obtains;

[0088] 3), the glue-spraying surface of the metal wheel hub obtained in step 2) is pre-sprayed with a high-temperature reactive adhesive;

[0089] 4), the pre-sprayed metal hub obtained in step 3) is preliminarily dried for 2-3 hours in an environment of 5-30°C under a humidity of ≤75%;

[0090] 5), preheating the preliminary dried pre-sprayed metal hub obtained in step 4) at 110-120° C. for 2-10 hours;

[0091] 6) Put the metal hub pre-sprayed with adhesive obtained in step 5) into the injection mold cavity for positioning and fixing, then close the mold, and then use a 160-260T low-pressure injection molding machine to inject liquid thermoplastic polyurethane material from the pouring machine scr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com