Energy-saving combination power system of engine of automobile

An automobile engine and combined power technology, which is applied to vehicle components, auxiliary drive devices, control devices, etc., can solve the problems of unutilized sliding inertia energy, shortening the sliding distance of the car, and low conversion efficiency, so as to increase and reduce the sliding distance. The effect of reducing energy consumption and drag resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

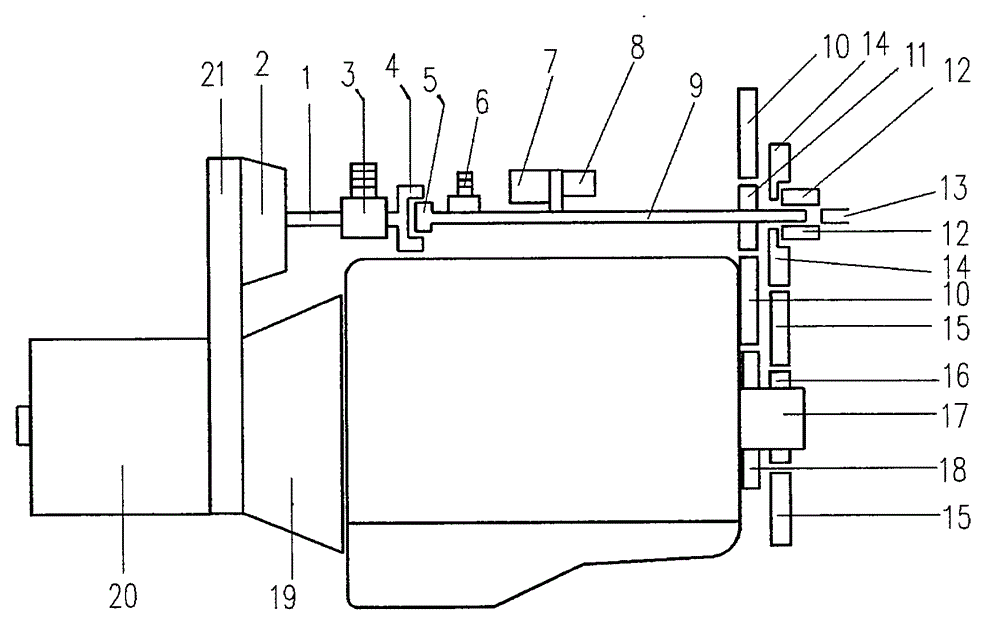

[0009] In the accompanying drawings, the power take-off device (21) is connected with the power input shaft of the transmission (20) and the power output shaft of the main clutch (19), and the power of the automobile engine can be transmitted to the secondary clutch (2) by the main clutch The power input shaft, the sliding inertial energy and the braking energy of the automobile can also be transmitted to the power input shaft of the auxiliary clutch (2) by the power input shaft of the transmission (20). When the automobile engine accelerates to drive the automobile, the auxiliary clutch (2) does not combine , the power is driven by the crankshaft gear (18) fixedly connected with the crankshaft (17) of the engine to drive the deceleration one-way gear driving wheel (10) to reduce the speed, and then through the deceleration one-way gear driven wheel (11) to the accessory drive shaft (9) , so that the main air compressor (6), the air conditioner compressor (7) and the generator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com