Tyre sorting device and tyre sorting method

A sorting device and tire technology, applied in the field of palletizing machinery, can solve the problems of incapable of making full use of the workshop height, not significantly reducing the labor intensity, and the line body occupies a large area, so as to achieve reduced labor costs, stable electrical control, The effect of precise positioning control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

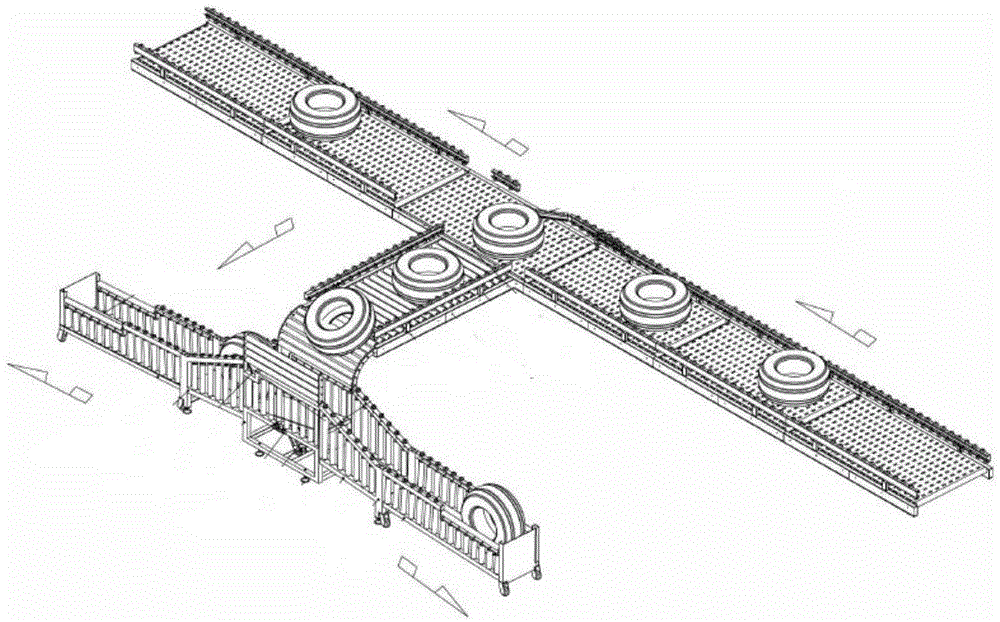

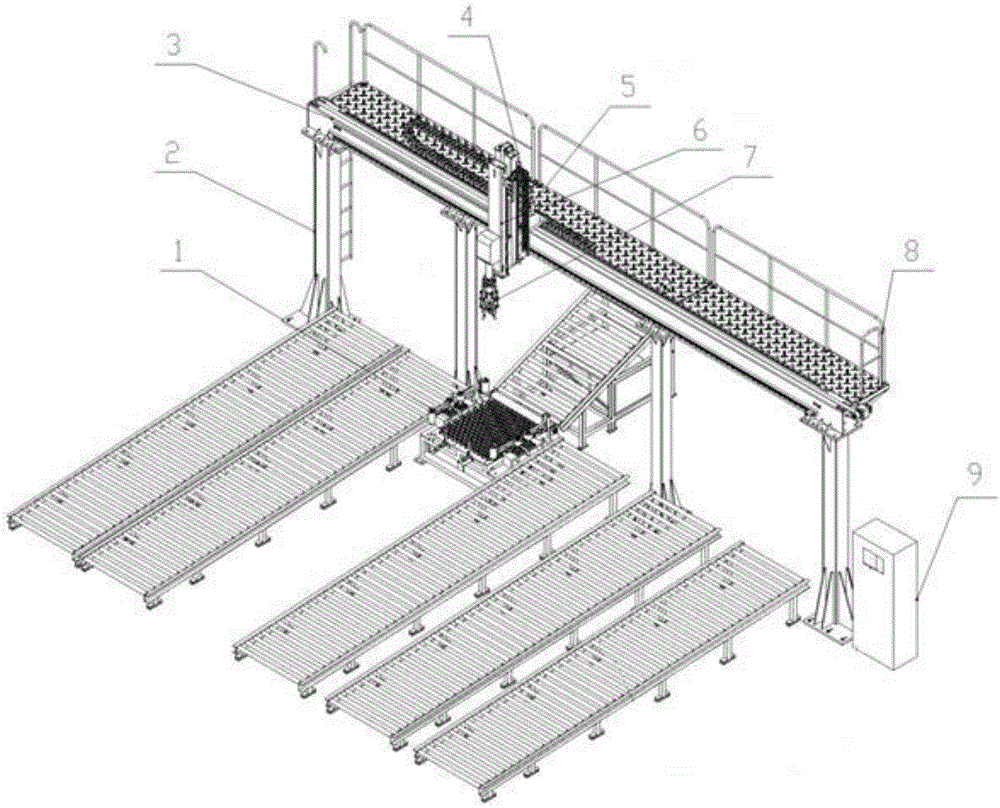

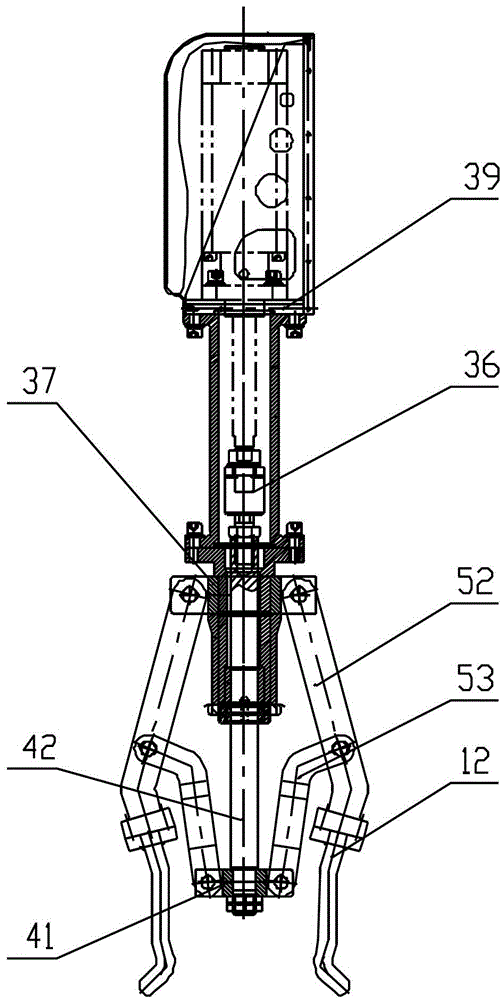

[0032] The sorting device is arranged after the dynamic balance uniformity detection line, and is mainly used to classify and stack the detected tires, which includes a column 2, a beam 3, a sorting platform 26, a manipulator 4, and a driving manipulator 4 that moves laterally along the beam The first servo motor 5, the crossbeam 3 straddles the top of the two columns 2, the sorting platform 26 is used to carry tires, and a positioning mechanism is arranged on it. The positioning mechanism includes a cylinder 32 and a centering device 1, and the power output end of the cylinder 32 The connecting rod structure is fixed, one end of the centering device 1 is fixed on the connecting rod structure, and the other end is coaxially connected with the rotating gear 28 through the shaft 29; the cylinder 32 drives the cylinder rotating rod 31 connected with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com