A long-wave absorbing photoinitiator containing phosphate group based on epoxy compound and preparation method thereof

An epoxy compound and phosphate-containing technology, which is applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problem of no photoinitiated polymerization activity, etc., and achieve improved interface light Effects of priming efficiency, improvement of adhesion, and enhancement of adhesion retention characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

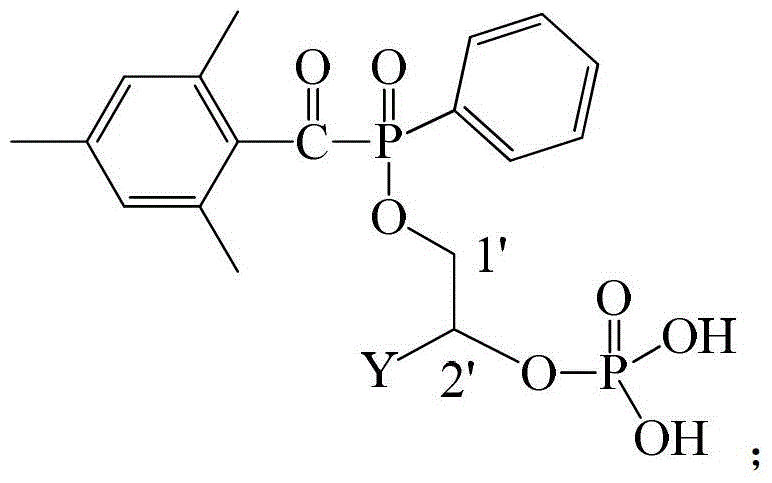

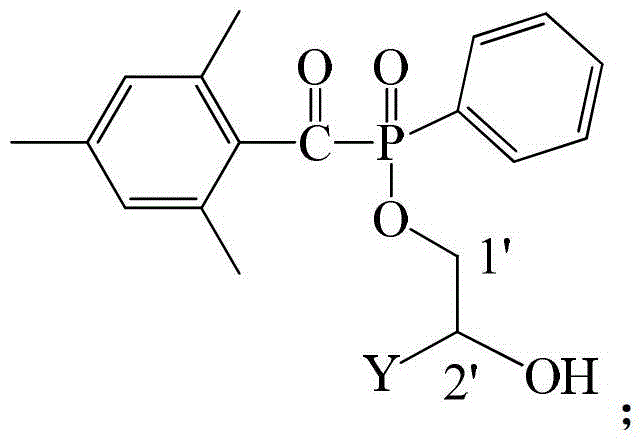

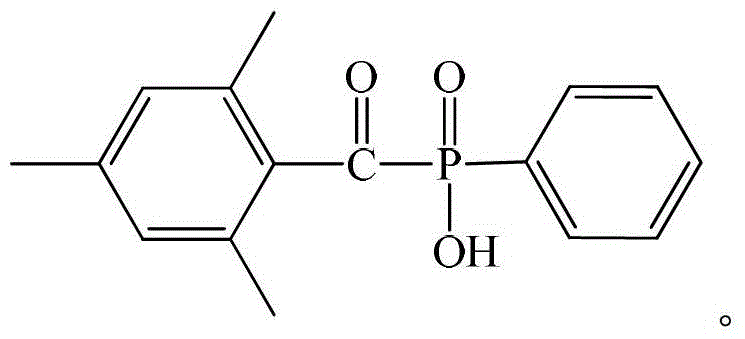

[0024] A kind of preparation method of the long-wave absorbing photoinitiator containing phosphate group based on epoxy compound, comprises the steps: the 2,4,6-trimethylbenzoylphenyl phosphonic acid alkyl group containing 2'-position hydroxyl The ester and phosphorus pentoxide can be reacted under the condition of water, wherein, 2,4,6-trimethylbenzoylphenyl phosphonic acid alkyl ester containing 2′-hydroxyl and phosphorus pentoxide, The molar ratio of water is 1.0:(0.4-0.6):(0.4-0.6), preferably 1:0.5:0.5; the 2,4,6-trimethylbenzoylbenzene containing 2'-position hydroxyl The structural formula of alkyl phosphonate is as follows:

[0025]

[0026] Among them, Y is H, alkyl and haloalkyl with 1 to 4 carbon atoms, ROCH 2 -, R'COOCH 2 One of -; said R represents an alkyl group of 1 to 8 carbon atoms or an alkyl group containing a benzene ring, and said R' represents an alkyl group of 1 to 7 carbon atoms or an aryl group or an alkyl group containing a benzene ring of alkyl....

Embodiment 1

[0048] Take 28.8g (0.1mol) of 2,4,6-trimethylbenzoylphenylphosphonic acid and add it to a three-necked bottle filled with 100ml of toluene, stir and heat to 60°C to completely dissolve the substituted phosphonic acid, and circulate at low temperature Pump down the temperature of the system to 0°C, add 6.4g (0.11mol) of frozen propylene oxide, continue to stir and react at 0°C for 8 hours, and take a sample to measure the acid value below 5.0mg KOH / g, which is regarded as the completion of the reaction sign, the reaction is basically over. The solvent was distilled off under reduced pressure to obtain 34.5 g of the product 2,4,6-trimethylbenzoylphenylphosphonic acid-2′-hydroxypropyl ester. Structure detection 1 H NMR (d 6 -DMSO): δ(ppm)=1.17-1.22(m,3H),2.14(s,3H),2.34(s,6H),3.45(m,1H),4.18(m,2H),6.81(s, 2H) 7.42 (m, 2H), 7.68 (m, 1H), 7.76 (m, 2H).

Embodiment 2

[0050] As in Example 1, 10.1 g (0.11 mol) of epichlorohydrin was used instead of propylene oxide for reaction at 60°C for 5 hours to obtain the product 2,4,6-trimethylbenzoylphenylphosphonic acid-2 38.2 g of '-hydroxy-3'-chloropropyl ester. Structure detection 1 H NMR (d 6 -DMSO): δ(ppm)=2.13(s,3H),2.34(s,6H),3.40-3.57(m,2H),3.66(m,1H),4.19(m,2H),6.81(s, 2H) 7.44 (m, 2H), 7.69 (m, 1H), 7.75 (m, 2H).

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com