A circumferential back pressure

A back pressure device and pressure head technology, applied in the field of pressure control, can solve the problems of large opening pressure, increase movement resistance, increase opening pressure, etc., and achieve the effect of sensitive differential pressure response, avoiding clogging of channels, and ensuring closing strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

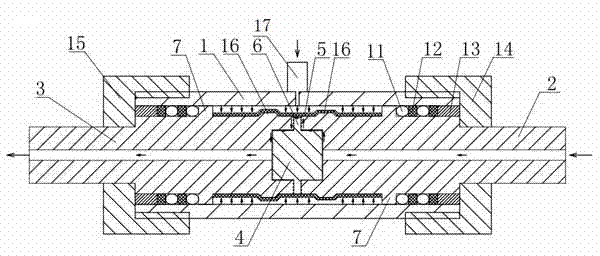

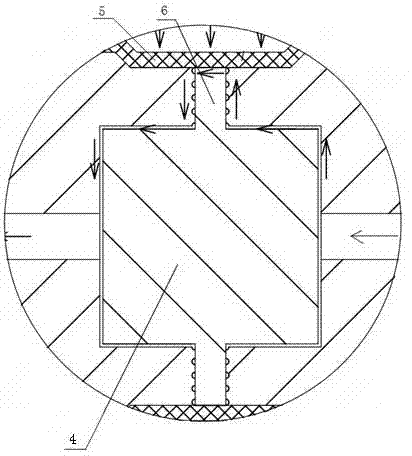

[0035]A circumferential back pressure device, comprising a sealed cylinder 1, in which a flexible sealing sleeve 5, a solid valve core 4, a back pressure joint I2 with a liquid input channel and a liquid output channel are fixed. The back pressure joint II3, the back pressure joint I2 and the back pressure joint II3 are provided with counterbore, the solid valve core 4 is clamped by the counterbore of the back pressure joint I2 and the counterbore of the back pressure joint II3, the The solid valve core 4 is provided with a valve core convex ring 6 located between the back pressure joint I2 and the back pressure joint II3; the flexible sealing sleeve 5 is set on the back pressure joint I2, the valve core convex ring 6 and the back pressure joint II3 , there is a gap between the flexible sealing sleeve 5 set on the spool convex ring 6 and the sealing cylinder 1, the back pressure joint I2, the solid spool 4, the spool convex ring 6, the back pressure joint II3 and Liquid channe...

Embodiment 2

[0040] A circumferential back pressure device, comprising a sealed cylinder 1, in which a flexible sealing sleeve 5, a solid valve core 4, a back pressure joint I2 with a liquid input channel and a liquid output channel are fixed. The back pressure joint 3II, the back pressure joint I2 and the back pressure joint II3 are provided with counterbore, the solid valve core 4 is clamped by the counterbore of the back pressure joint I2 and the counterbore of the back pressure joint II3, the The solid valve core 4 is provided with a valve core convex ring 6 located between the back pressure joint I2 and the back pressure joint II3; the flexible sealing sleeve 5 is set on the back pressure joint I2, the valve core convex ring 6 and the back pressure joint II3 , there is a gap between the flexible sealing sleeve 5 set on the spool convex ring 6 and the sealing cylinder 1, the back pressure joint I2, the solid spool 4, the spool convex ring 6, the back pressure joint II3 and Liquid chann...

Embodiment 3

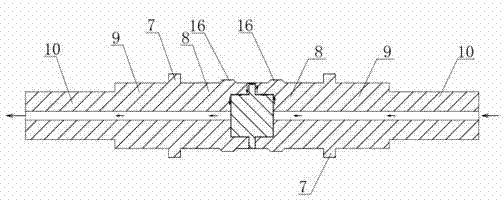

[0053] The difference from Example 2 is that in the present invention, there are multiple "O"-shaped sealing rings 11 and sealing retaining rings 12, and multiple "O"-shaped sealing rings 11 and sealing retaining rings 12 are alternately distributed in the sealing cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com