Electromagnetic micro valve integrated on micro-fluidic chip

A microfluidic chip and microvalve technology, applied in valve details, diaphragm valves, valve devices, etc., can solve problems such as unfavorable use by ordinary users, matching of portable instruments, complex technology, etc., and achieve wide application range, fast response, and easy operation good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical scheme of the present invention is further described below in conjunction with accompanying drawing and specific embodiment:

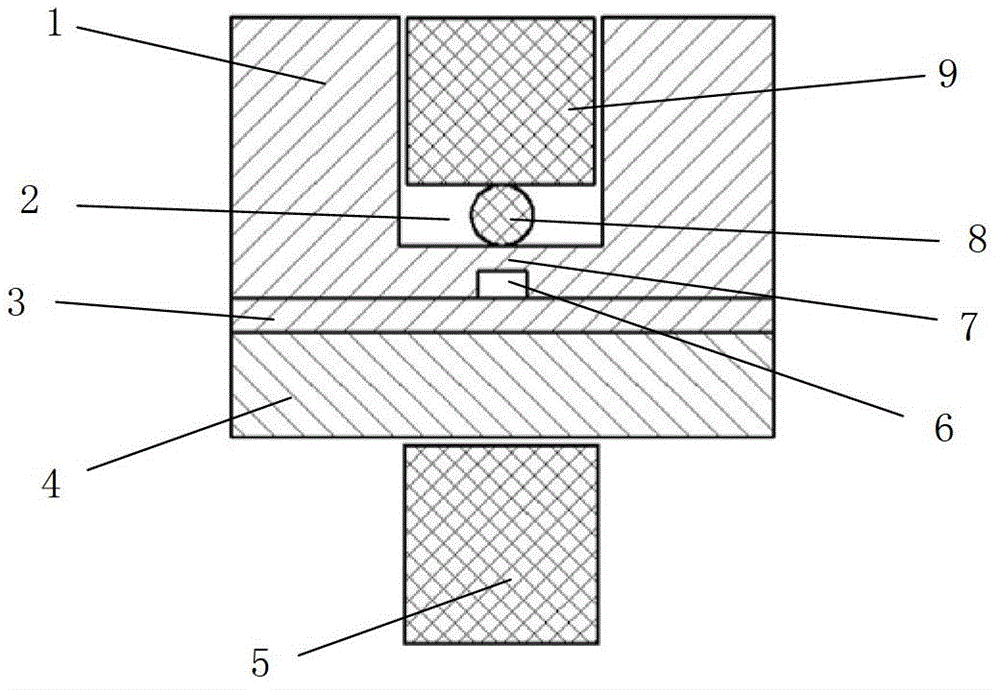

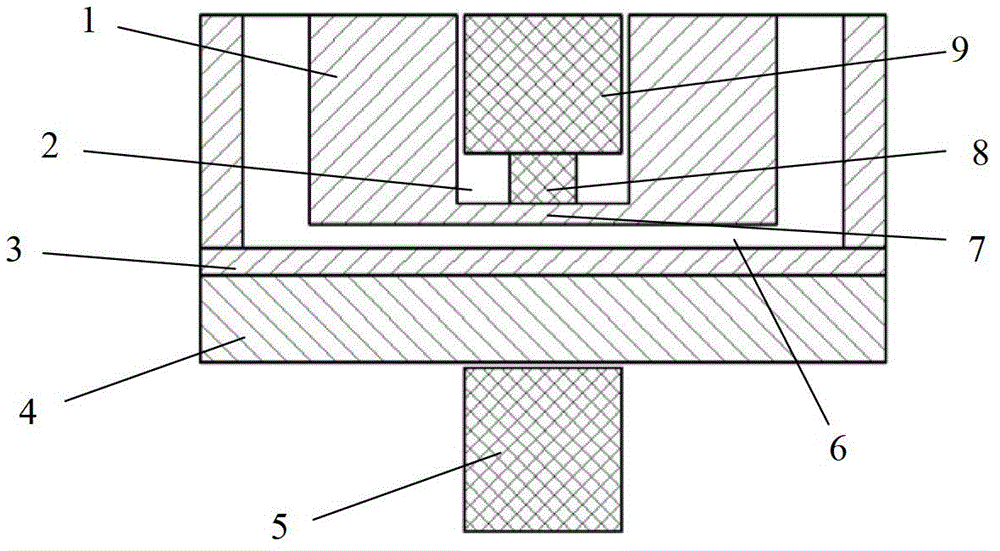

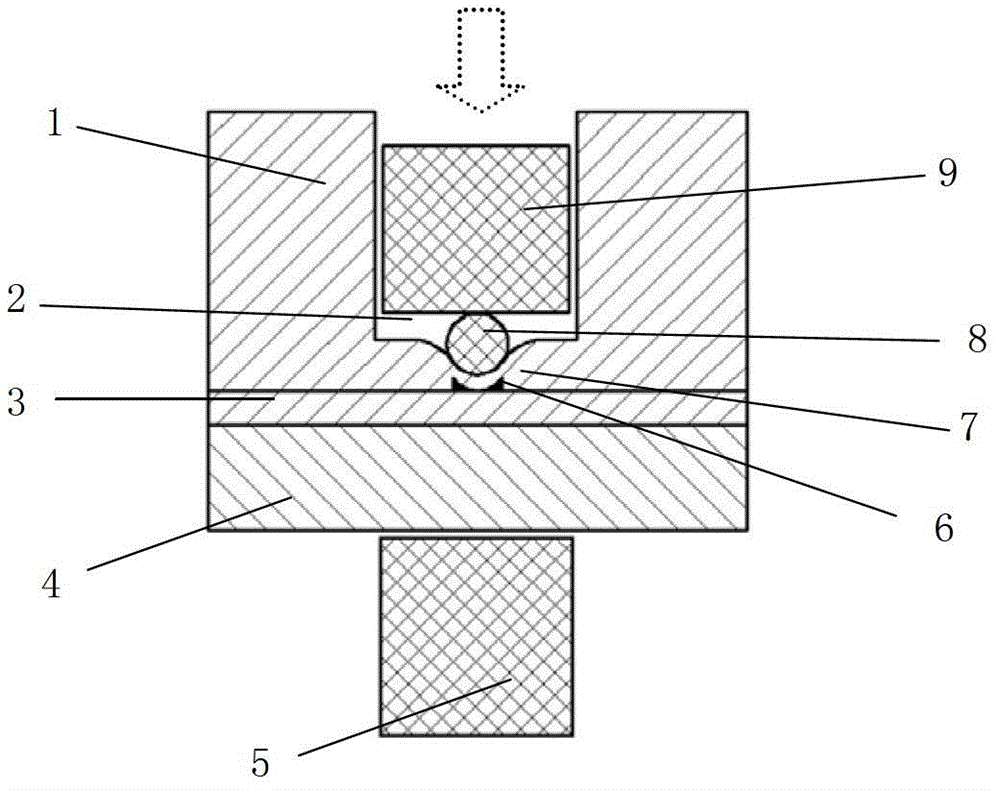

[0021] like figure 1 , figure 2 As shown, the electromagnetic microvalve integrated on the microfluidic chip provided by the present invention includes a permanent magnet 9 , an electromagnet 5 , a thimble 8 and a valve seat 2 . The microfluidic chip includes two layers, the upper layer is a PDMS chip 1, and the lower layer is a substrate 4; the substrate 4 is spin-coated with a PDMS coating 3, and the thickness of the spin coating is 0.5-1 mm; the bottom surface of the valve seat 2 is PDMS elastic film 7, and the bottom surface is the common wall where the valve seat 2 intersects with the fluid channel 6 of the microfluidic chip, the thickness of the elastic film can be 500 μm; the upper end of the valve seat communicates with the outside world; the thimble 8 is located at the PDMS elastic On the film 7, corresponding to the ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap