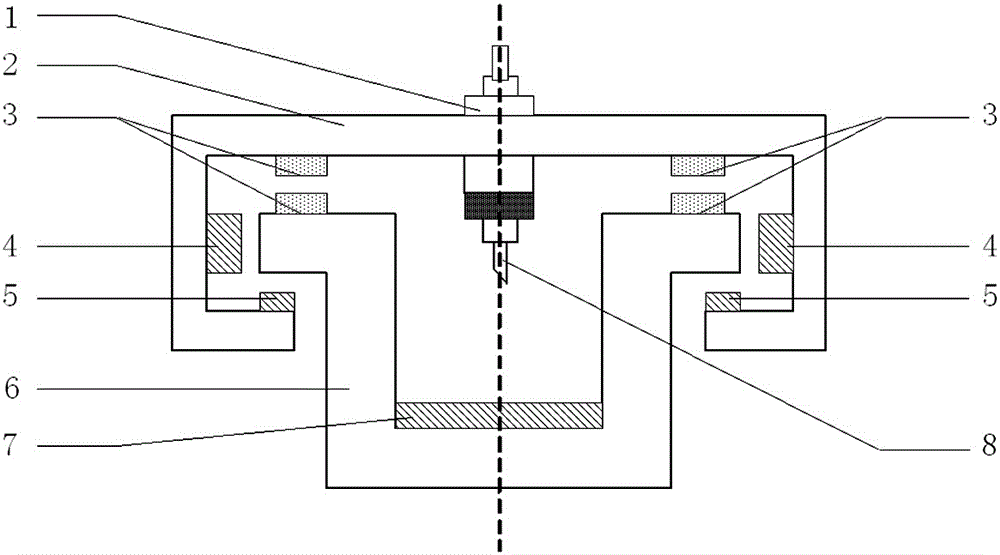

Control method of time-varying sliding mode variable structure and cross-coupling control maglev system

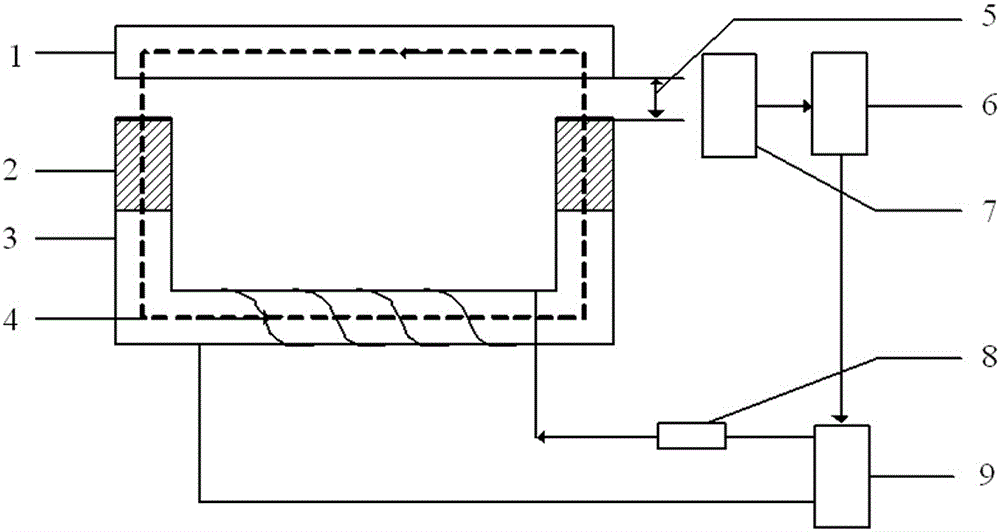

A sliding mode variable structure, cross-coupling technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as slow response speed, affecting the suspension height of moving beams, and reducing workpiece machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0345] The basic parameters of the magnetic levitation system: the mass of the moving beam m=600kg, the number of coil turns of the electromagnet winding N=380, the area of the electromagnet core A=0.65*0.03m 2 , resistance R=1Ω, support electromagnet output expected suspension air gap y=0.002m.

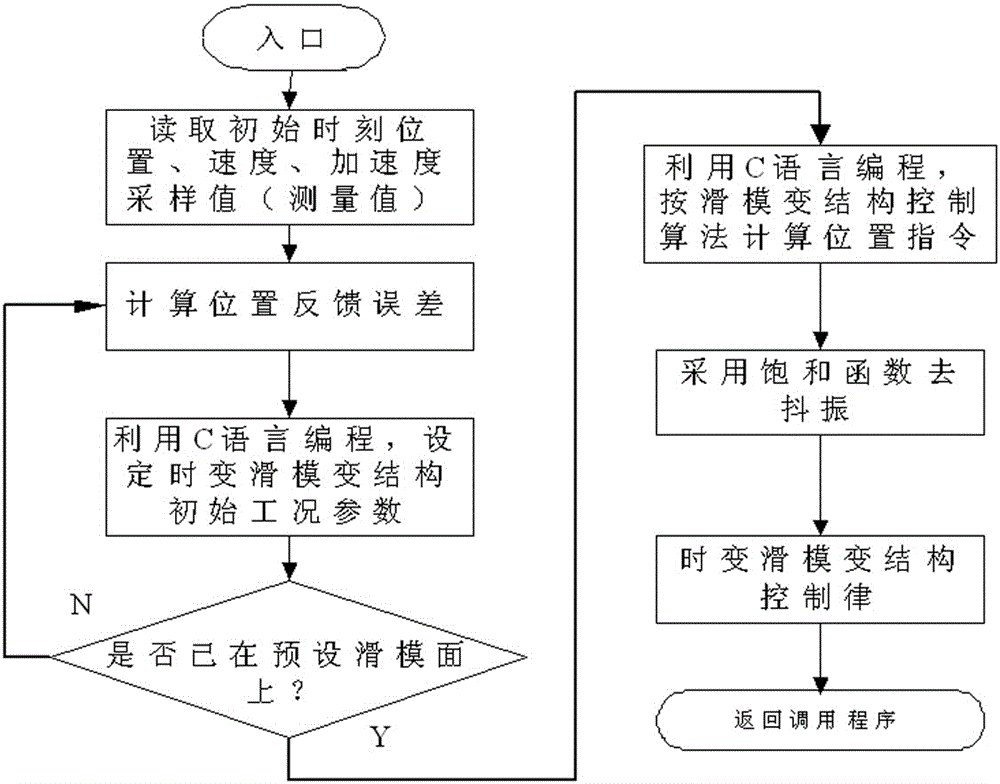

[0346] Time-varying sliding mode variable structure controller parameters: According to the existence conditions of the sliding mode surface and the stability conditions of the control law, a set of more suitable parameters of the time-varying sliding mode variable structure controller is obtained, that is, C 1 =300,C 2 =30, K=3000, λ=10.

[0347] then linear control law u c = [ 3000 σ + r ( 3 ) - φ ‾ x - d ‾ +...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com