Preparation method of solid oxide fuel cell Ln2NiO4 film cathode

A solid oxide, fuel cell technology, used in solid electrolyte fuel cells, battery electrodes, circuits, etc., can solve problems such as large contact resistance, achieve small electrode volume and weight, high electrochemical performance, and reduce contact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

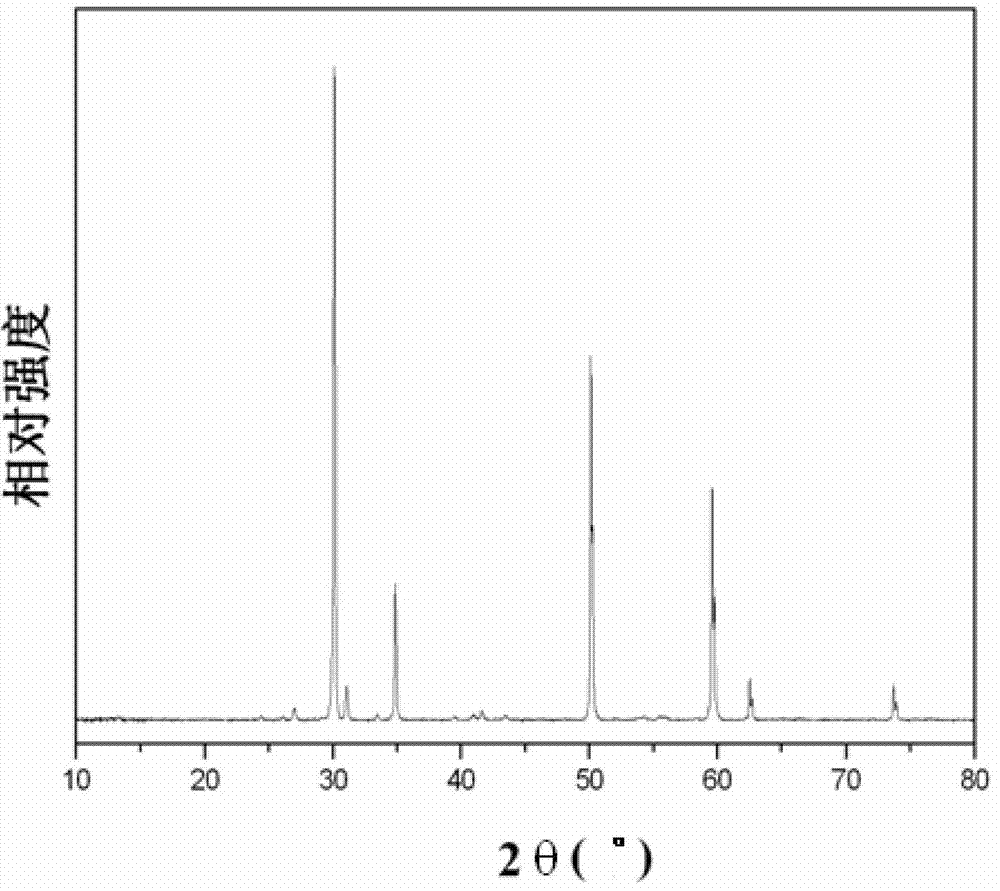

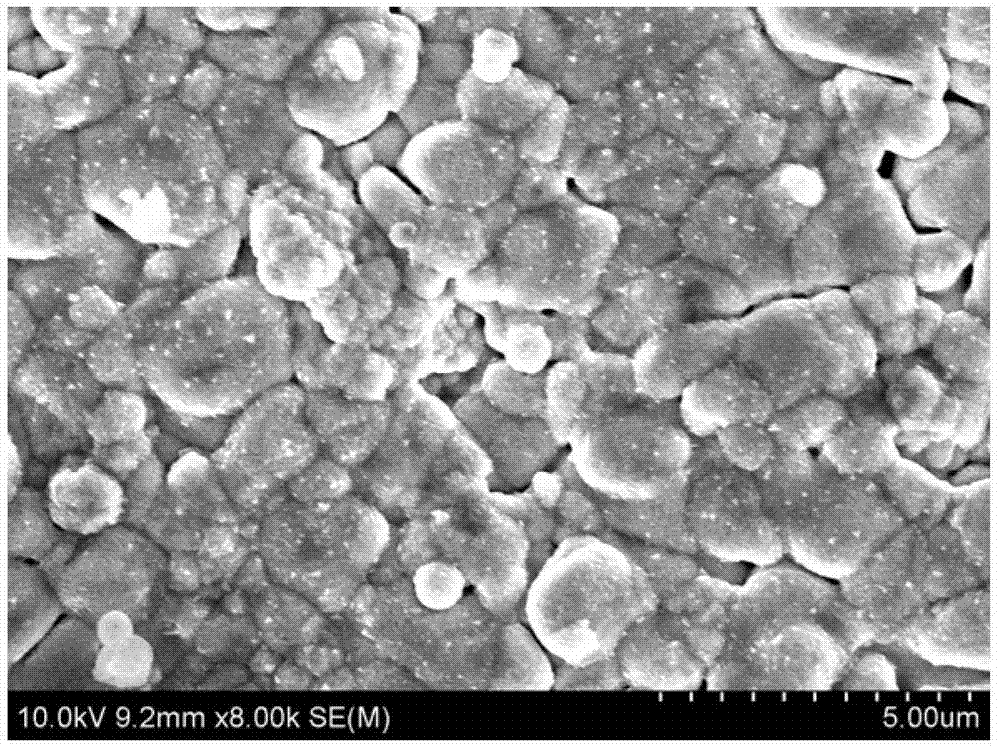

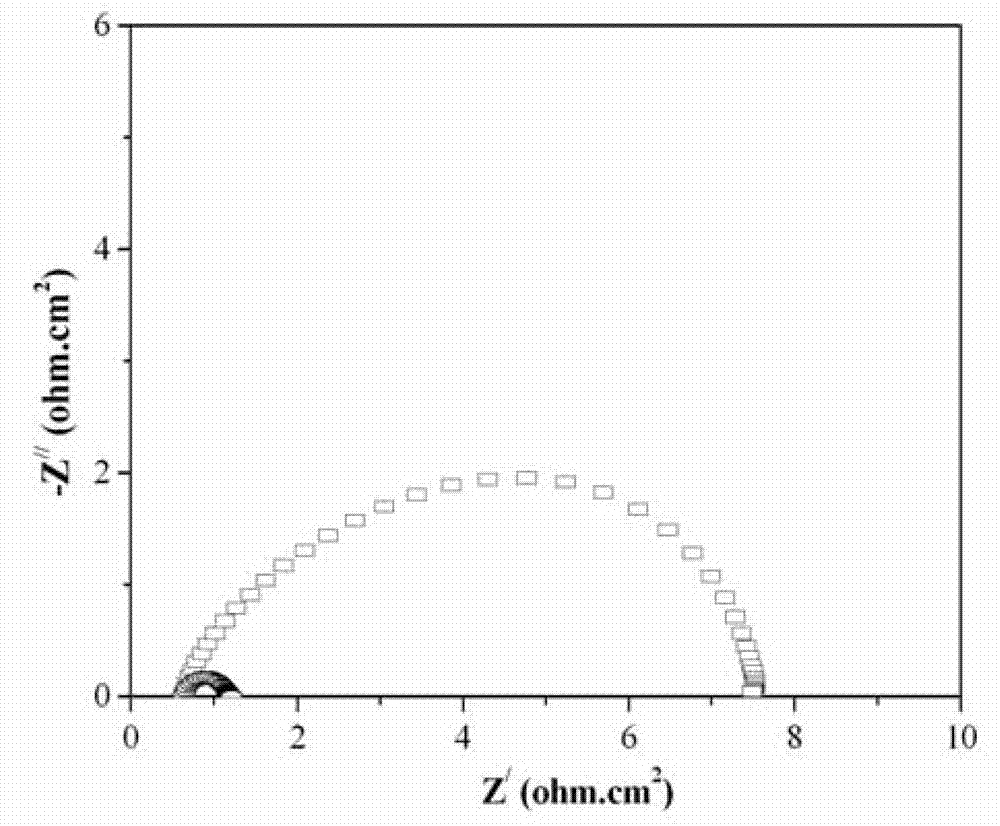

[0020] Specific implementation mode 1: The solid oxide fuel cell Ln of this implementation mode 2 NiO 4 The preparation method of the thin film cathode is specifically prepared according to the following steps:

[0021] 1. Mix and grind the rare earth oxide and NiO powder evenly, control the pressure at 100MPa-200MPa for steel mold pressing, and obtain a target precursor with a diameter of 60mm and a thickness of 5mm, and then put the target precursor in a high temperature In the furnace, the temperature is controlled at 800 ° C to 1000 ° C, and the sintering time is 8 hours to obtain Ln for sputtering thin films. 2 NiO 4 target;

[0022] Second, the solid electrolyte Ce 0.9 Gd 0.1 o 1.95 The powder is pressed into a steel mold at a pressure of 200MPa to 250MPa to obtain a substrate precursor with a diameter of 15mm and a thickness of 1mm, and then put the substrate precursor into a high-temperature furnace with a controlled temperature of 1400°C and a sintering time of ...

specific Embodiment approach 2

[0031] Specific embodiment two: this embodiment is the same as specific embodiment one: in step one, the control pressure is 150MPa to carry out steel mold pressing. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment is the same as Embodiment 1: in step 1, the temperature is controlled at 900°C. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com