Medical waste high temperature rotary-cut treatment process and treatment equipment

A technology for medical waste and treatment process, which is applied in the field of high-temperature rotary cutting treatment process and treatment equipment for medical waste, can solve the problems of inability to reuse waste, secondary pollution of waste, and cost a lot of manpower, and achieves compact structure and high degree of automation. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

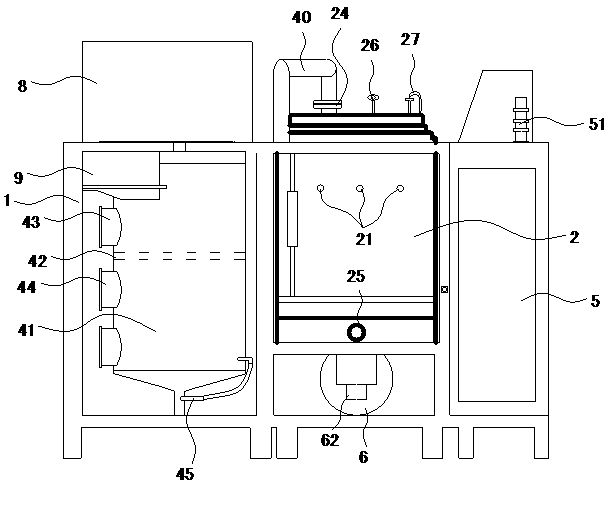

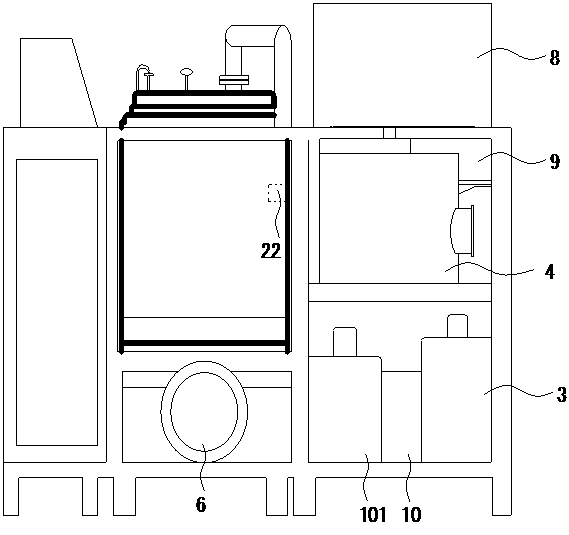

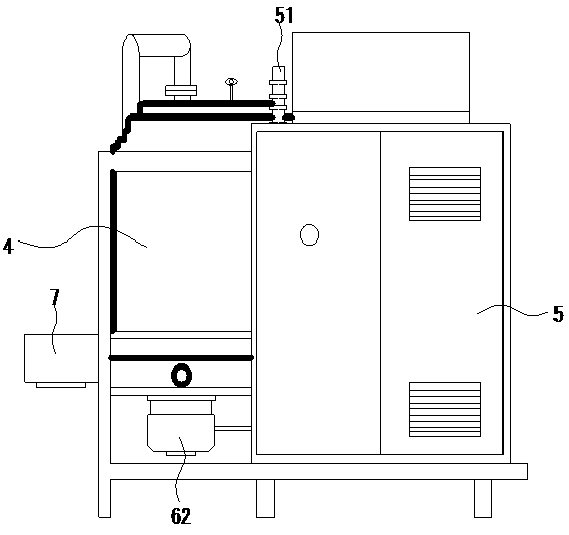

[0046] The process steps of high-temperature rotary cutting treatment of medical waste include:

[0047] (1) Load medical waste into the disinfection cabin;

[0048] (2) The motor drives the rotary blade at the bottom of the disinfection chamber to cut the waste at a speed of 900 rpm, and the disinfectant is injected into the disinfection chamber from the disinfectant nozzle on the inner wall of the disinfection chamber;

[0049](3) After step (2) runs for 4 minutes, increase the rotation speed of the rotating blade at the bottom of the disinfection chamber to 1420 rpm, so that the heat energy generated by the waste under violent agitation and friction can heat the waste to the pre-programmed temperature of 130°C;

[0050] (4) Inject clean water into the disinfection cabin, and the water will directly turn into water vapor after fully contacting the surface of the high-temperature treatment object;

[0051] (5) Reduce the rotation speed of the rotating blade at the bottom of ...

Embodiment 2

[0055] The process steps of high-temperature rotary cutting treatment of medical waste include:

[0056] (1) Load medical waste into the disinfection cabin;

[0057] (2) The motor drives the rotary blade at the bottom of the disinfection chamber to cut the waste at a speed of 1200 rpm, and the disinfectant is injected into the disinfection chamber from the disinfectant nozzle on the inner wall of the disinfection chamber;

[0058] (3) After step (2) runs for 8 minutes, increase the rotation speed of the rotating blade at the bottom of the disinfection chamber to 1700 rpm, so that the heat energy generated by the waste under the violent agitation and friction can make the waste heat up to the pre-programmed temperature of 170°C;

[0059] (4) Inject clean water into the disinfection cabin, and the water will directly turn into water vapor after fully contacting the surface of the high-temperature treatment object;

[0060] (5) Reduce the rotation speed of the rotating blade at ...

Embodiment 3

[0064] The process steps of high-temperature rotary cutting treatment of medical waste include:

[0065] (1) Load medical waste into the disinfection cabin;

[0066] (2) The motor drives the rotating blade at the bottom of the disinfection chamber to cut the waste at a speed of 1100 rpm, and the disinfectant is injected into the disinfection chamber from the disinfectant nozzle on the inner wall of the disinfection chamber;

[0067] (3) After step (2) runs for 4 minutes, increase the rotation speed of the rotating blade at the bottom of the disinfection chamber to 1550 rpm, so that the heat generated by the waste under violent agitation and friction can heat the waste to the pre-programmed temperature of 148°C;

[0068] (4) Inject clean water into the disinfection cabin, and the water will directly turn into water vapor after fully contacting the surface of the high-temperature treatment object;

[0069] (5) Reduce the rotation speed of the rotating blade at the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com