Dust-collecting pole plate of wet water-film electrostatic precipitator

A technology of electrostatic precipitator and dust collection plate, applied in the direction of electrode structure, electrostatic separation, etc., can solve problems such as increased water consumption, difficulty in cleaning dust, and inability to form a water film on the surface of the plate, so as to reduce water consumption and high The effect of dust collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

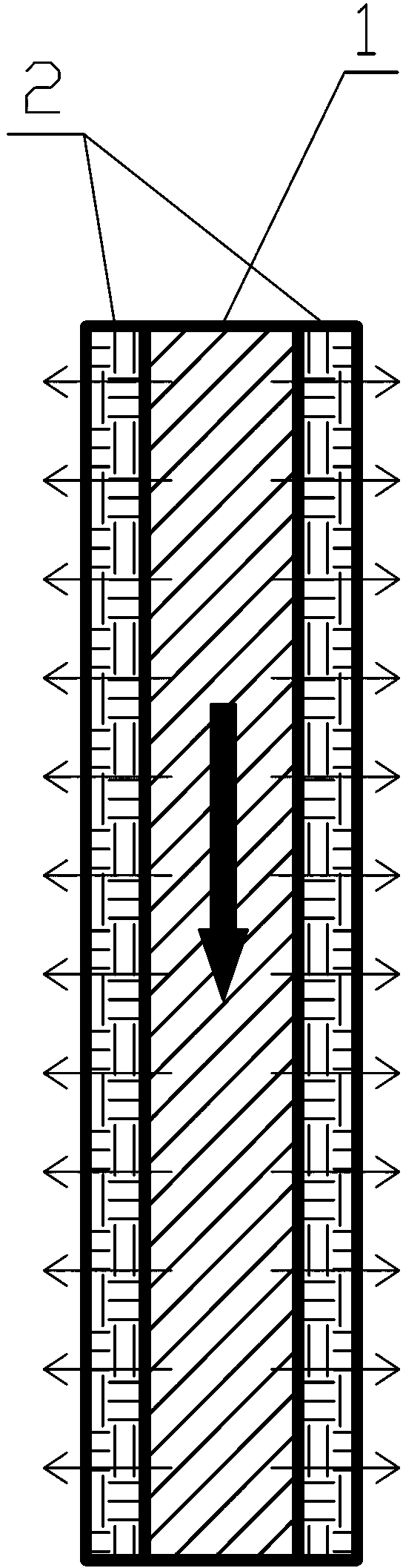

[0025] Such as figure 1 The dust collection pole plate of the first wet water film electrostatic precipitator shown is mainly composed of an inner material layer 1 and an outer material layer 2 attached on both sides thereof. The inner material layer 1 is a porous plate layer made of glass fiber material, and its thickness is 5-7mm. The outer material layer 2 is a braided material layer made of hydrophilic cotton and linen material, and its thickness on one side is 1.5-2mm. In this embodiment, the porosity distribution of the outer material layer 2 and the inner material layer 1 adopts a structure uniformly distributed from top to bottom. Specifically, the porosity of the inner material layer 1 at each height is 0.7, and the porosity of the outer material layer 2 at each height is 0.7×0.6=0.42. During manufacture, the inner material layer 1 and the outer material layer 2 can be bonded and extruded as a whole on the outer periphery.

[0026] In the existing electrostatic pre...

Embodiment 2

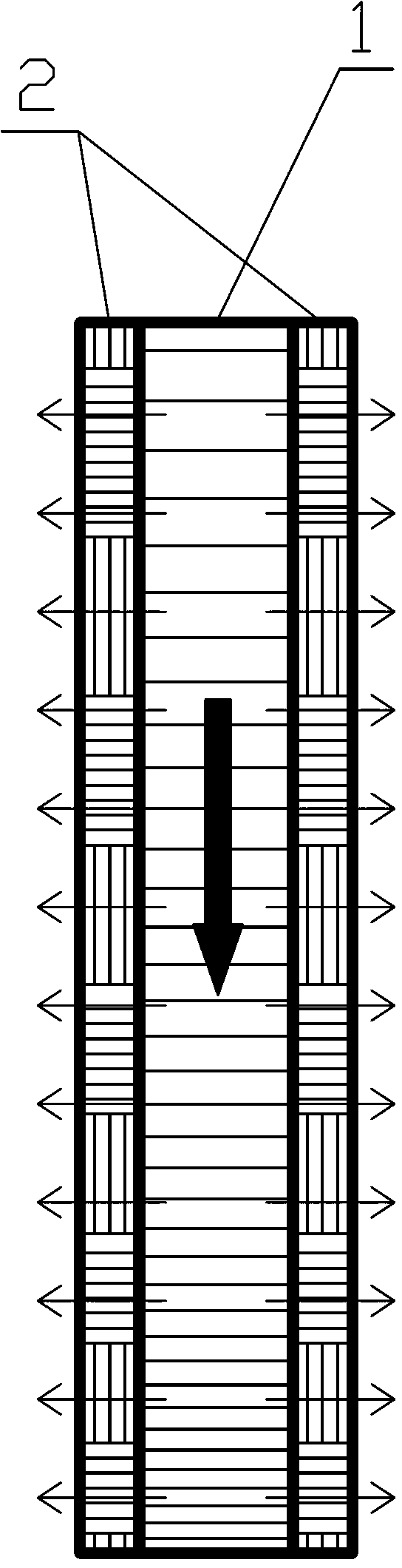

[0029] Such as figure 2 The dust collection pole plate of the second wet water film electrostatic precipitator shown includes an inner material layer 1 and an outer material layer 2 attached on both sides thereof. The inner material layer 1 is a braided material layer made of glass fiber, and its thickness is 2-4mm. The outer material layer 2 is a braided material layer made of hydrophilic carbon fiber material, and the thickness of one side thereof is 0.8-1.0 mm. In this embodiment, the porosity distribution of the outer material layer 2 and the inner material layer 1 adopts a structure that gradually decreases from top to bottom. Specifically, the porosity of the inner material layer 1 gradually decreases from 0.8 to 0.4 from top to bottom, and the porosity of the outer material layer 2 gradually decreases from 0.8×0.5=0.40 to 0.4×0.5=0.20 from top to bottom. During manufacture, the inner material layer 1 and the outer material layer 2 are bonded, extruded or assembled in...

Embodiment 3

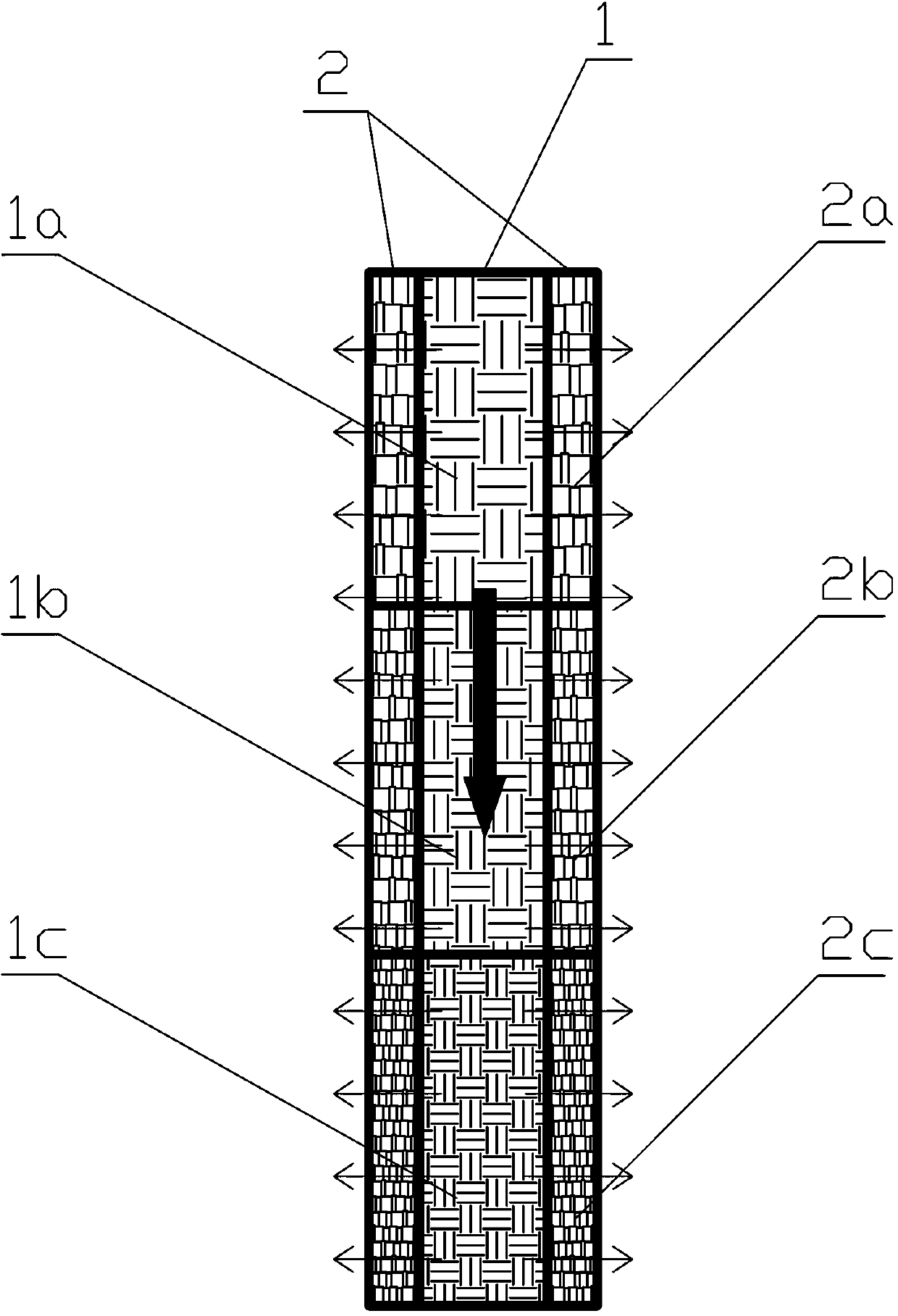

[0033] Such as image 3 The dust collecting pole plate of the third wet water film electrostatic precipitator also includes an inner material layer 1 and an outer material layer 2 attached on both sides thereof. The inner material layer 1 is a porous plate layer made of flame-retardant ceramic material, and its thickness is 4-9 mm. The outer material layer 2 is a braided material layer made of resin fibers, and the thickness of one side thereof is 1.8-2 mm. In this embodiment, the porosity distribution of the outer material layer 2 and the inner material layer 1 adopts a structure in which the distribution decreases in sections from top to bottom. Specifically, the inner material layer 1 is composed of the upper section 1a of the inner material layer, the middle section 1b of the inner material layer, and the lower section 1c of the inner material layer, wherein: the porosity of the upper section 1a of the inner material layer is 0.7, and the porosity of the middle section 1b o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com