Control system and control method for load cable cleaning and maintaining line

A technology of traction wire rope and control system, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., which can solve the problems of high power usage, high pulling force, and poor maintenance effect, so as to improve the level of automation and safety performance, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in detail below in conjunction with accompanying drawing:

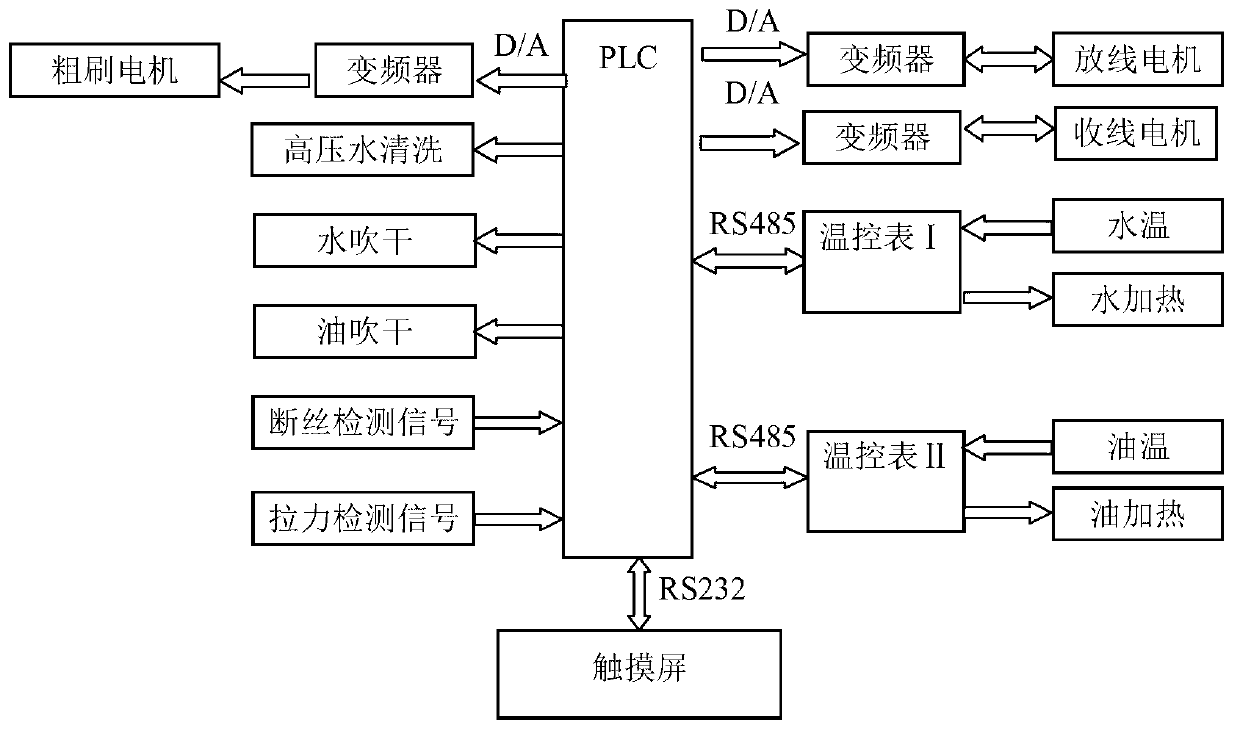

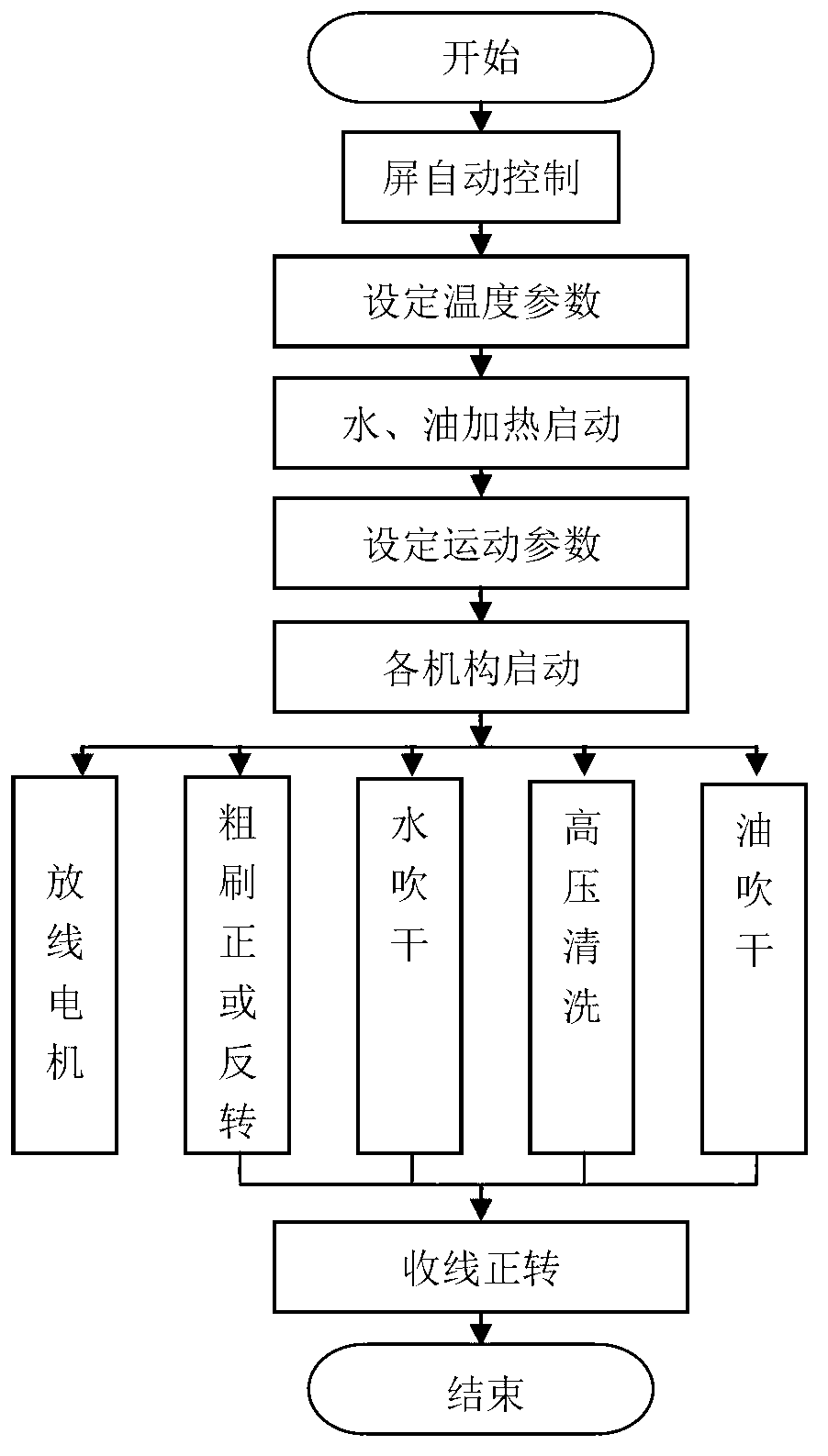

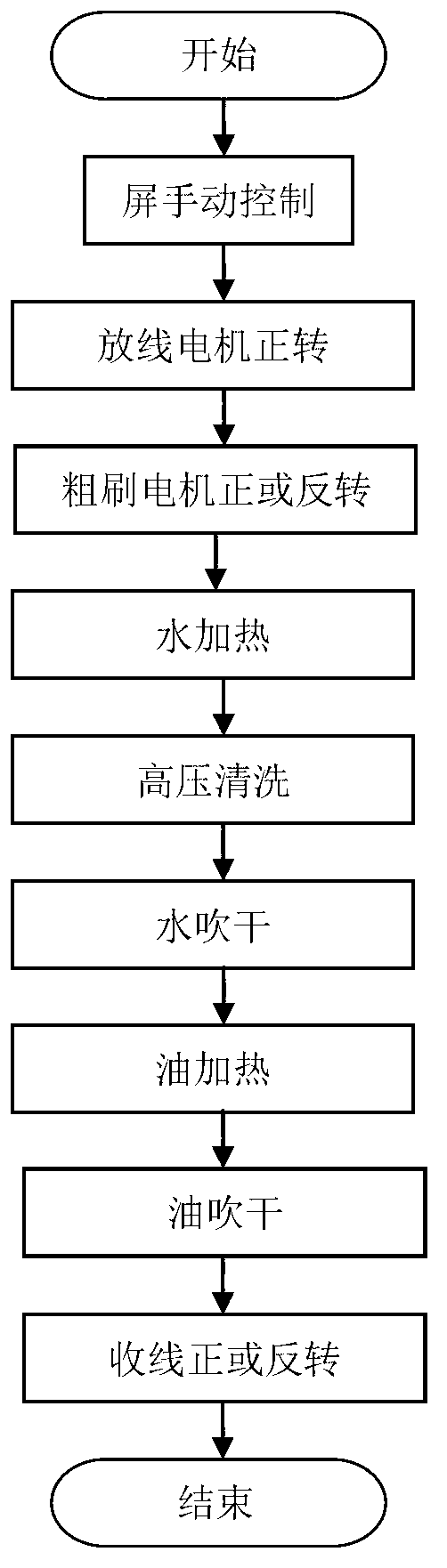

[0041] The structure diagram of the control system of the present invention is as follows figure 1 As shown, it includes a controller, and the input end of the controller is connected to a broken wire detection device and a tension detection device, and its output end is connected to a wire release device, an oil drying device, a water drying device, a high-pressure water cleaning device and a rough brush device, wire take-up device, and the controller is connected with the temperature control device of the water heating device and the oil heating device through the RS485 bus. The controller is a PLC controller, and the PLC controller communicates with a touch screen.

[0042] The wire take-up device includes a wire take-up motor, a frequency converter and a wire take-up roller, the frequency converter is connected with a controller, and the frequency converter controls the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com