Structural system and construction method of bridge-type prefabricated reinforced concrete channel slab wear-resistant pavement

A technology of reinforced concrete and pavement structure, applied in the direction of roads, roads, special pavements, etc., to achieve the effect of convenient hoisting, lower project cost and less environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

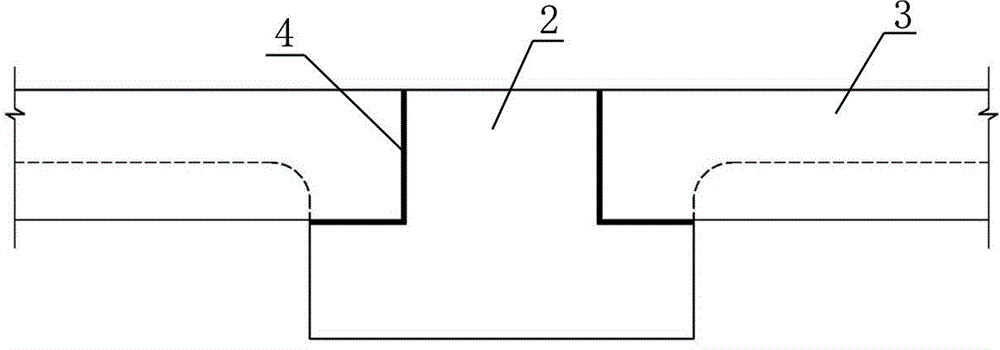

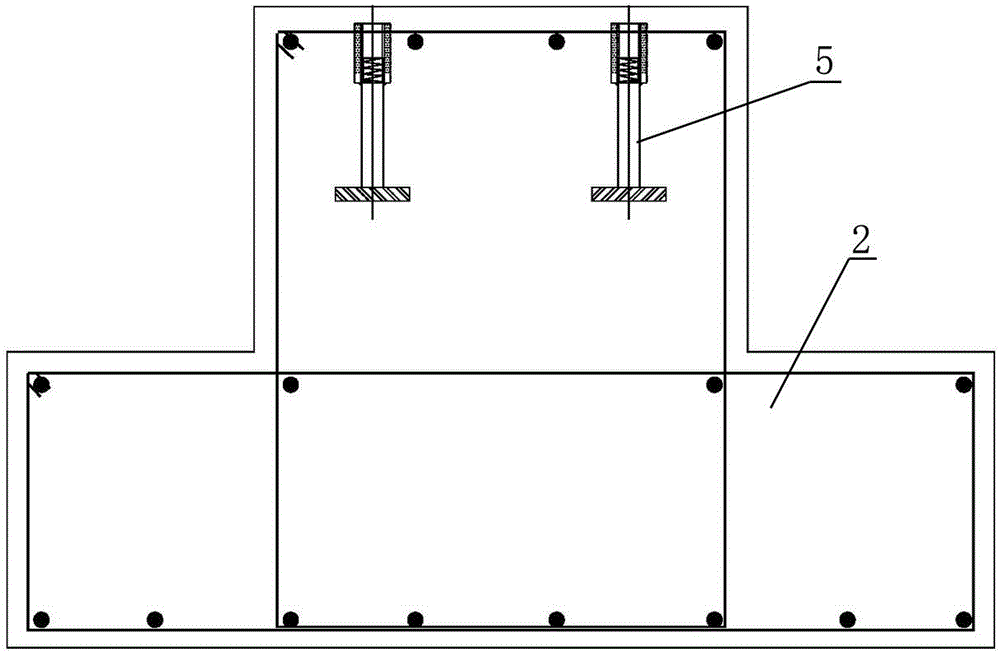

[0046] Examples see Figure 1 to Figure 6 As shown, a bridge type prefabricated reinforced concrete channel plate wear-resistant pavement structure system includes a panel and a foundation. The panel is a prefabricated reinforced concrete channel panel 3, and the foundation is a prefabricated reinforced concrete strip foundation 2. The cross section of the prefabricated reinforced concrete strip foundation 2 is T-shaped, the prefabricated reinforced concrete channel panel 3 is a reinforced concrete rectangular parallelepiped, the upper surface of which is provided with a steel fiber concrete surface layer 6, and the bottom of the rectangular channel is opened, Its two sides are framed at the steps of the prefabricated reinforced concrete strip foundation 2, and the contact surface of the prefabricated reinforced concrete channel panel 3 and the prefabricated reinforced concrete strip foundation 2 is padded with L-shaped rubber pads 4.

[0047] A suspension ring 1 is pre-embedded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com