Laboratory testing method for multi-field-of-view star sensor

A technology of star sensor and testing method, which is applied in the direction of instruments, measuring devices, etc., to achieve the effect of increasing versatility and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

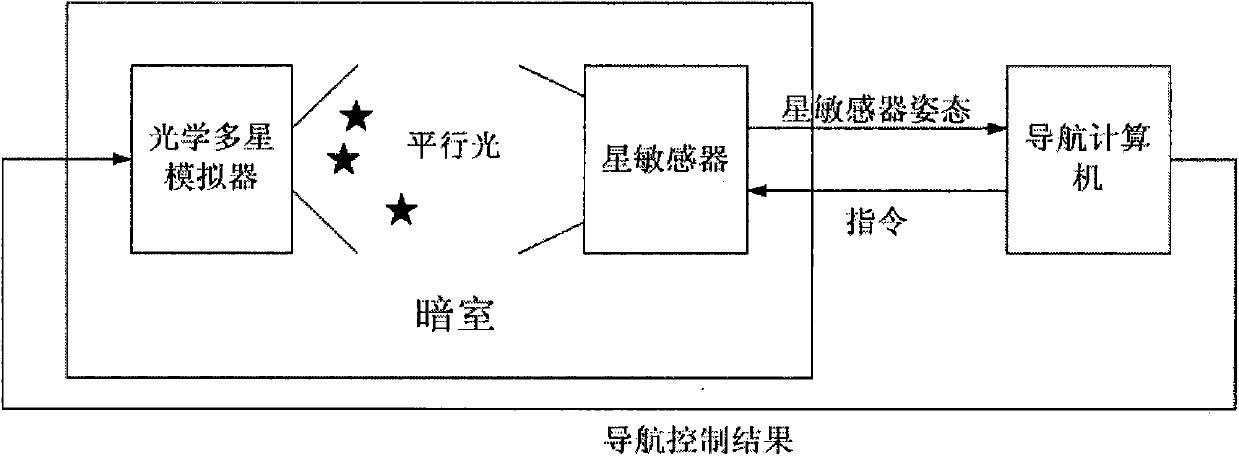

Problems solved by technology

Method used

Image

Examples

Embodiment 1

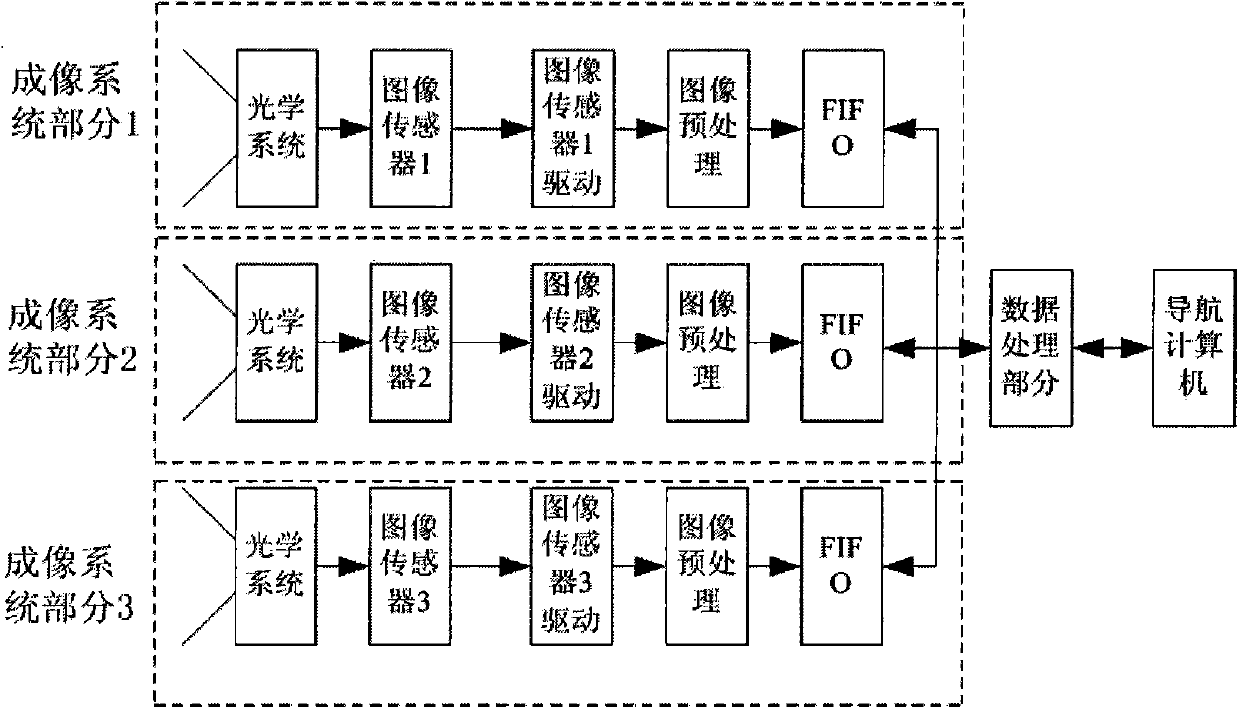

[0042]Like the single-field star sensor, the multi-field star sensor (here the three-field star sensor is used as an example to illustrate the multi-field star sensor test method, the same below) is mainly divided into two parts in terms of system composition : Imaging system part and data processing part. If the imaging system part contains two, it is called a dual-field star sensor, if the imaging system part contains three, it is called a three-field star sensor, and so on. Generally, there will be no more than three imaging systems, and all imaging systems share A data processing part, each imaging system part includes an optical system module, a detector module and a detector driver module. Each detector driving module separately controls the control timing signal of the image sensor and the star map preprocessing circuit, which is generally implemented by an FPGA chip. After preprocessing, multiple star images are sent to the data processing part of the star sensor thro...

Embodiment 2

[0074] Main performance indicators of star sensor:

[0075] Field of View: 14°×14°

[0076] Area array: 1024×1024

[0077] Detected magnitude: 6Mv

[0078] Data update rate: 15Hz

[0079] Parameters of the first multi-satellite simulator, the second multi-satellite simulator and the third multi-satellite simulator:

[0080] Field of view (°): 14×14 (software can be adjusted, the actual displayed field of view is the field of view of the simulation software)

[0081] Spectral range: visible light band 0.42-0.75

[0082] Resolution (pixels): 1024×1024

[0083] Single star resolution: better than 40″

[0084] Contrast ratio: 2000:1

[0085] Simulated magnitude (Mv): 0-9

[0086] Image display refresh rate (Hz): 50-80

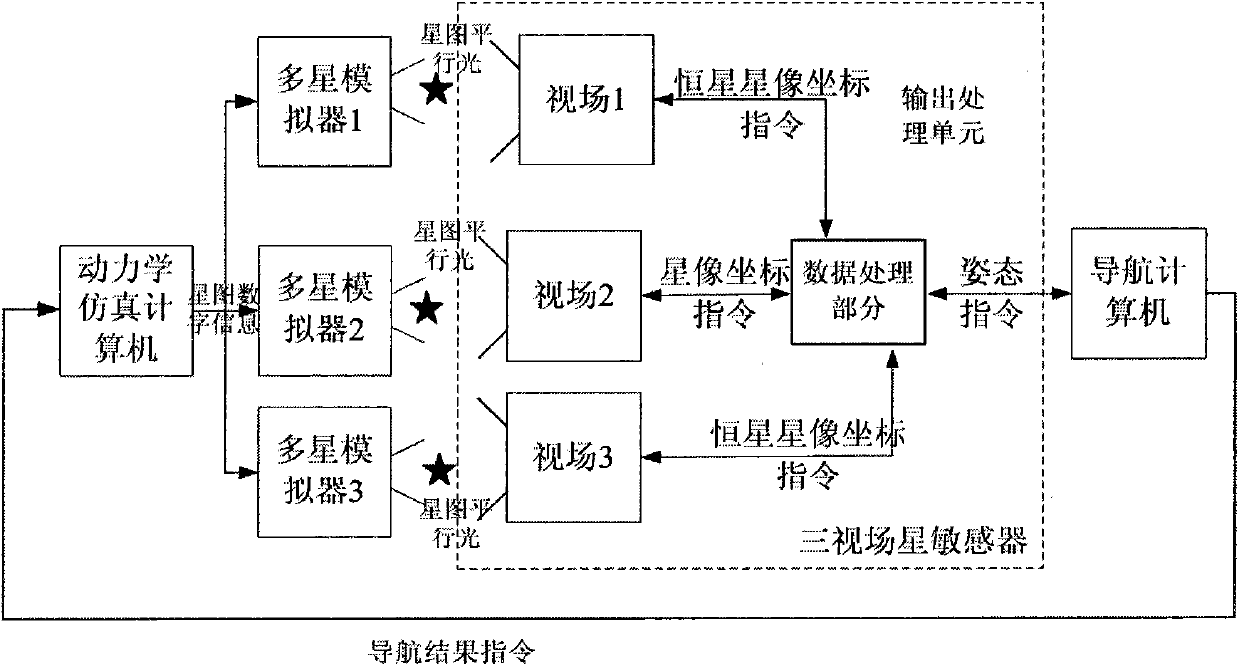

[0087]We selected a certain model of three-field star sensor. The models of the three multi-satellite simulators are all SSM-1. The dynamics simulation computer and the signal lines of the three multi-star simulators of SSM-1 make the first field of view ...

Embodiment 3

[0093] Such as Figure 7 As shown, this embodiment is an implementation of a multi-field star sensor laboratory testing method. In order to further improve the real-time performance of data transmission, all signal transmissions use LVDS electrical characteristics, and the navigation computer transmits navigation result instructions through LVDS For the dynamics simulation computer, the dynamics simulation computer decodes after receiving the navigation result instruction, and the orbit recursion algorithm of the dynamics simulation computer is realized by ARM, because the ARM processing is serial, and the three The field of view must receive the star map parallel light signal of the star simulator at the same time, and the FPGA processing is parallel, so the ARM sends the calculation result to the FPGA, and the FPGA simultaneously sends the star map signals of the three fields of view to the Multi-satellite simulator, multi-satellite simulator adopts SSM-1 type, the contrast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com