Squirrel-cage type asynchronous motor energy efficiency online monitoring method based on measurable electrical amount

An asynchronous motor and squirrel-cage technology, which is applied in the field of on-line monitoring of the energy efficiency of squirrel-cage asynchronous motors based on measurable electrical quantities, can solve problems such as the difficulty of directly calculating the operating efficiency and the inability to directly measure the output mechanical power of the motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

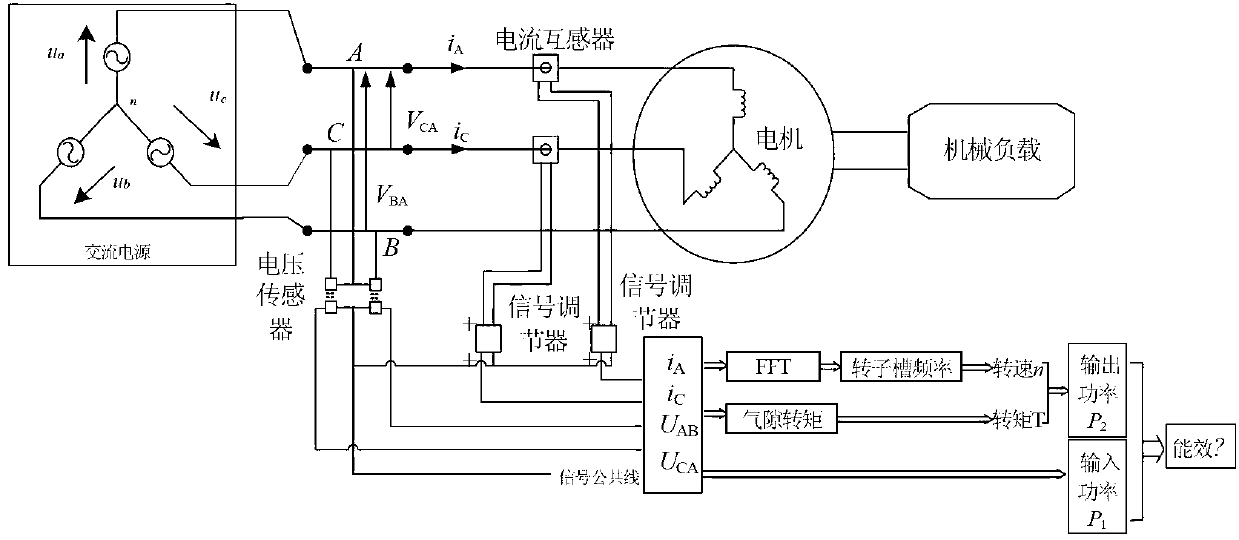

[0084] Taking the Y132S-4 and 5.5kW motors with 36 and 32 slots in the stator and rotor as examples, the identification of the speed of the squirrel-cage asynchronous motor will be further explained through the attached drawings. figure 1 It is a schematic diagram of an energy efficiency online identification system for a squirrel-cage asynchronous motor, in which voltage transformers and current transformers are used to collect stator three-phase voltage and current, and the rotor slot can be obtained by performing FFT analysis and torque calculation on the collected electrical quantities Frequency and output torque. During the test, the sampling frequency of each electrical quantity is 10kHz, and the sampling time is 1s.

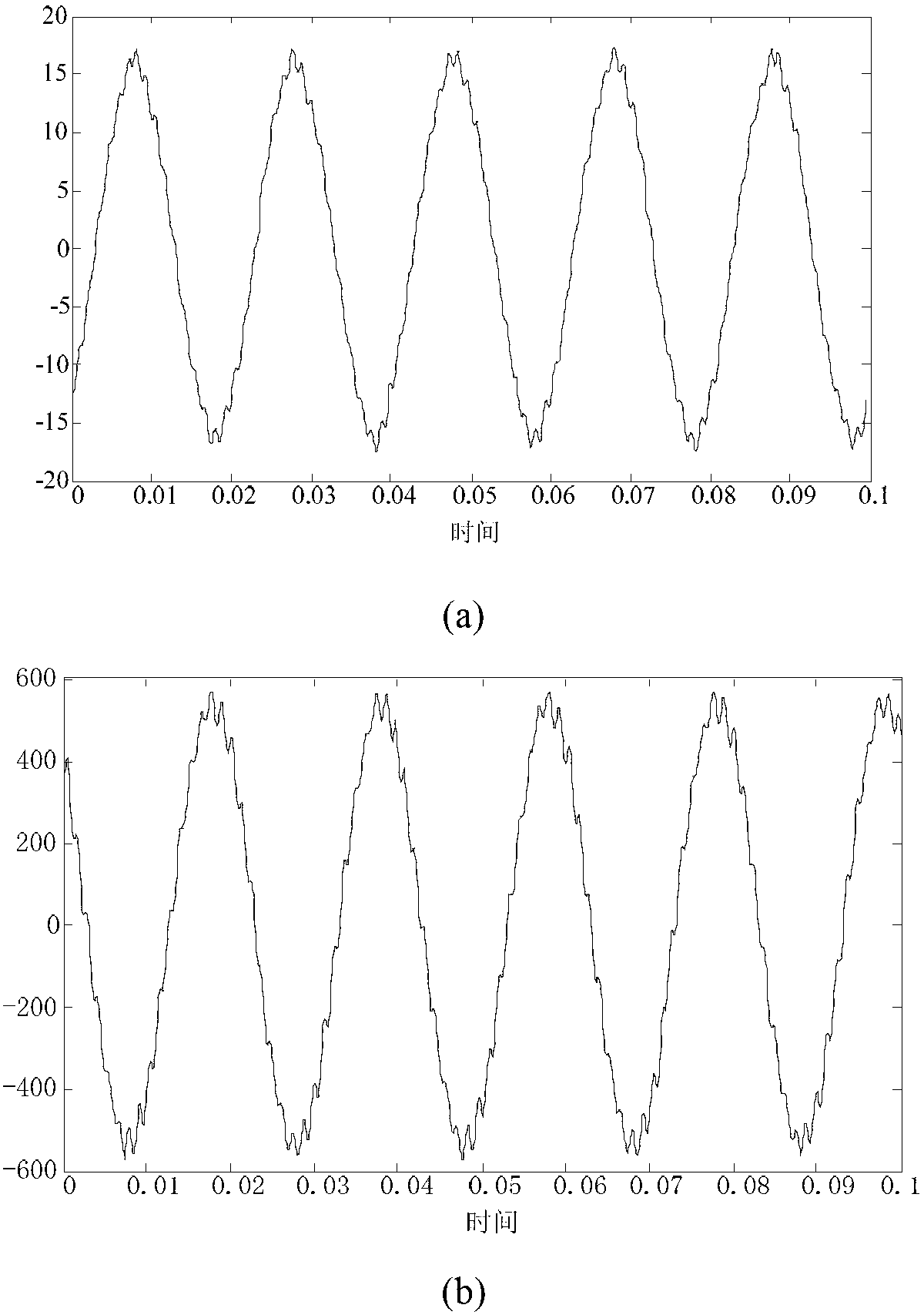

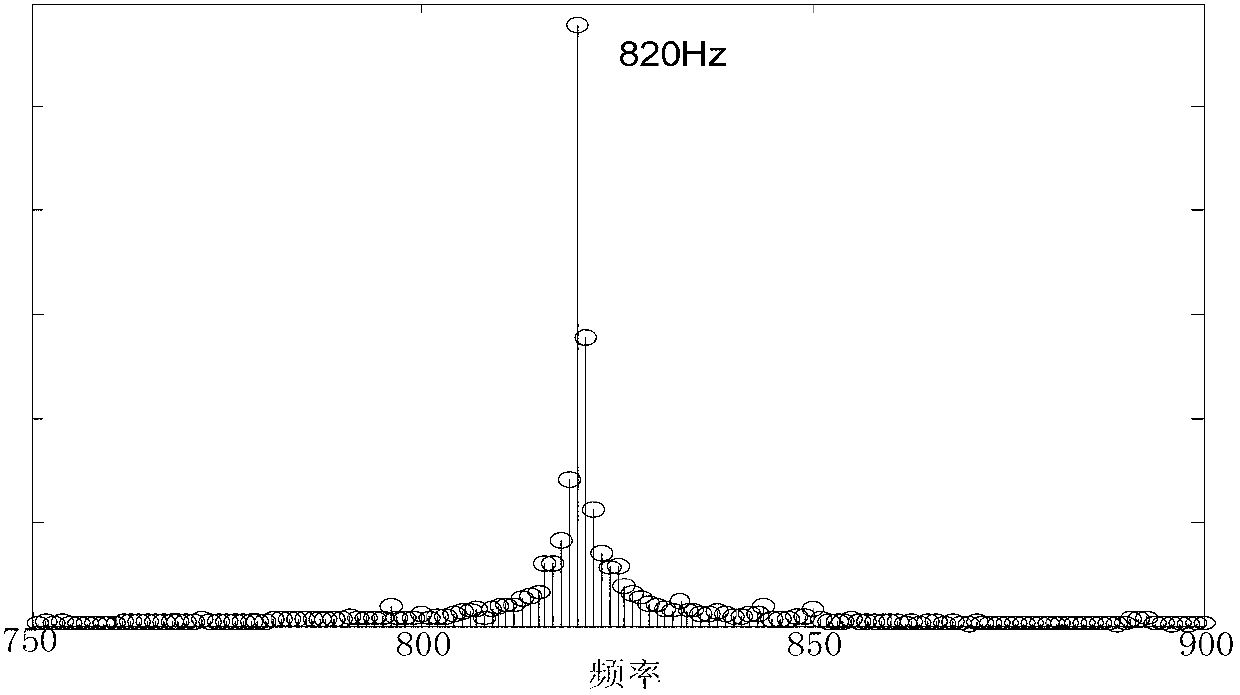

[0085] figure 2 (a) The stator current waveform diagram shown; figure 2 (b) The stator voltage waveform shown in (b). image 3 It is a 5.5kW squirrel-cage asynchronous motor with a rated voltage of 380V and a 100% load condition. The stator current spe...

Embodiment 2

[0089] Taking Y132S-4 and 5.5kW motors with 36 and 32 stator and rotor slots as examples, the identification of the speed of squirrel-cage asynchronous motors is further explained through the attached drawings.

[0090] Figure 5 It is a 5.5kW squirrel-cage asynchronous motor with a rated voltage of 380V and a load condition of 75%. The stator current spectrum is obtained by fast Fourier analysis of the stator current. From the figure, it can be clearly identified that the rotor slot frequency is 828Hz, and then According to formula (1), the real-time speed of the motor is 1458.75r / min, and the motor speed measured by the actual torque meter is 1459.2r / min. Figure 6 In order to use the air-gap torque method to obtain the motor air-gap torque waveform through the analysis of the motor stator current and voltage data, it can be seen from the figure that the air-gap torque of the motor fluctuates slightly around 26.97Nm. The identified output torque is 26.37Nm, and the actual o...

Embodiment 3

[0094] Taking Y132S-4 and 5.5kW motors with 36 and 32 stator and rotor slots as examples, the identification of the speed of squirrel-cage asynchronous motors is further explained through the attached drawings.

[0095] Figure 7 It is a 5.5kW squirrel-cage asynchronous motor with a rated voltage of 380V and a 50% load condition. The stator current spectrum is obtained by fast Fourier analysis of the stator current. From the figure, it can be clearly identified that the rotor slot frequency is 835Hz, and then According to formula (1), the real-time speed of the motor is 1471.9r / min, and the motor speed measured by the actual torque meter is 1471.4r / min. Figure 8 In order to use the air-gap torque method to obtain the motor air-gap torque waveform through the analysis of the motor stator current and voltage data, it can be seen from the figure that the air-gap torque of the motor fluctuates slightly around 19.3Nm. The identified output torque is 18.75Nm. The actual output to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com