Compact type electric vehicle battery liquid cooling device

An electric vehicle battery and liquid cooling technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of major breakthroughs in the performance of power batteries, affecting battery performance and life, and temperature differences in exothermic battery packs, etc., to achieve It is convenient for interior layout, improves anti-seismic performance, and has good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

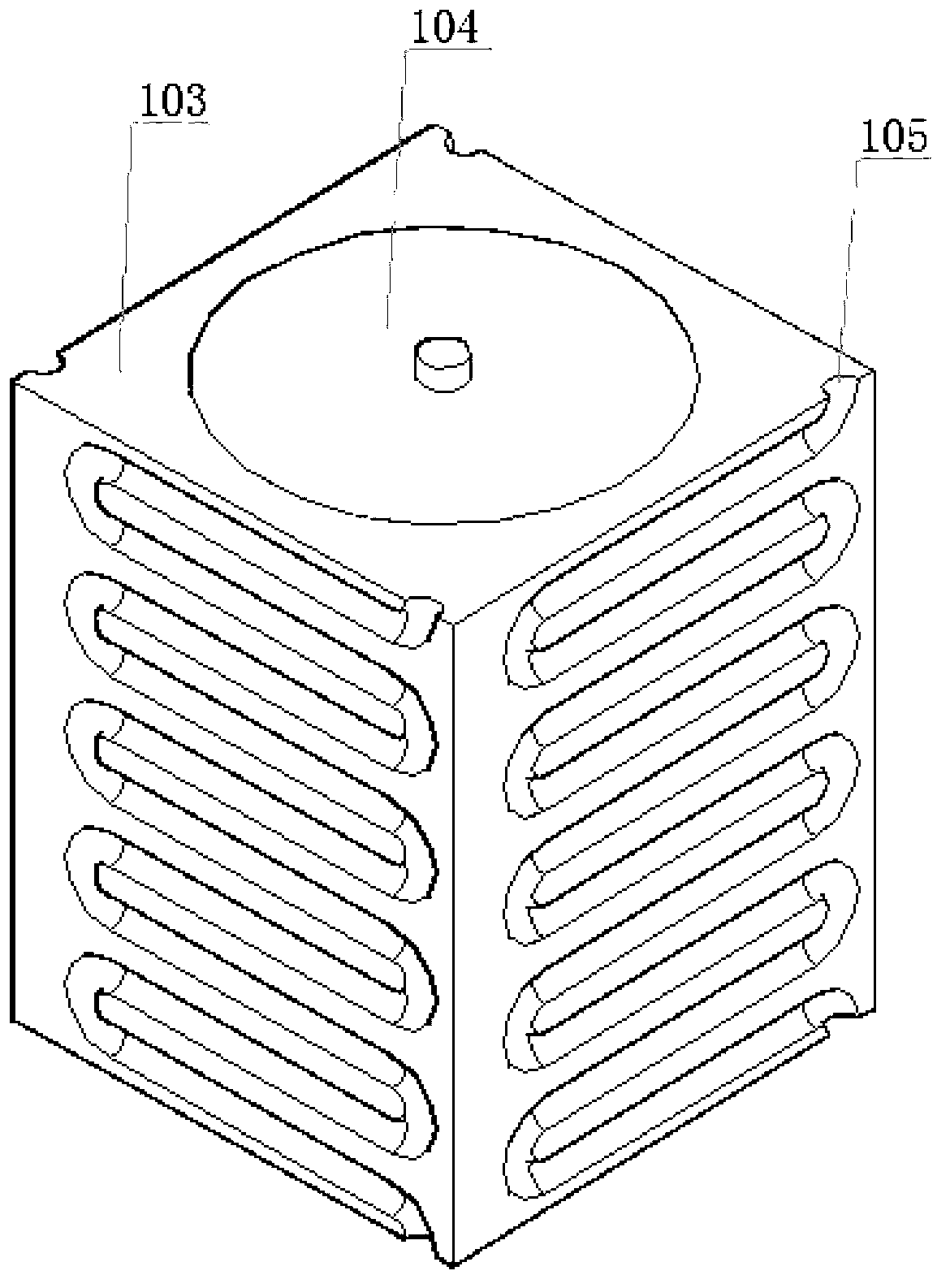

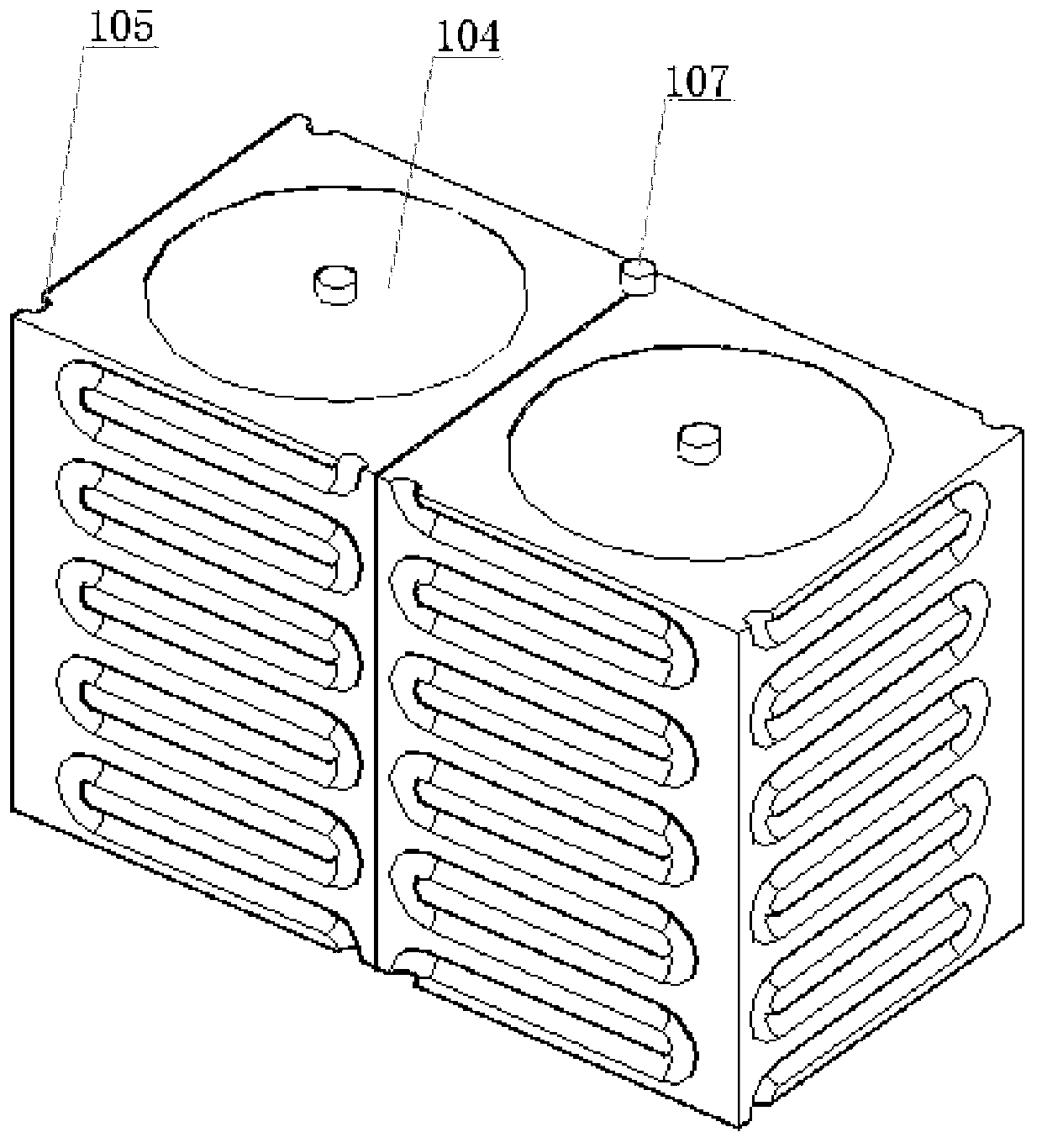

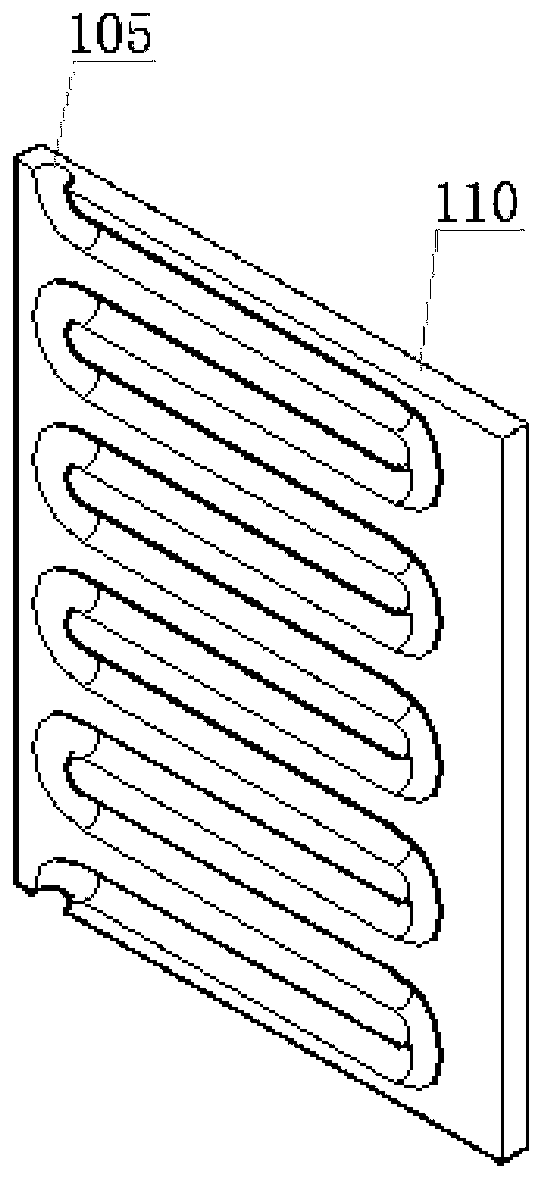

[0033] like figure 1 Shown: a compact electric vehicle battery liquid cooling device, including a battery box 102, the battery box 102 is provided with a plurality of interconnected battery modules, and the battery module is composed of a single battery 104 inserted into a heat-conducting shell 103 , the inner wall of the heat conduction housing 103 is bonded to the outer wall of the battery, the outer wall of the heat conduction housing is provided with a cooling pipe 107, and the cooling pipe 107 is installed in the channel 105 of the outer wall of the heat conduction housing, and the channel 105 It is a semicircle, and the channel 105 is attached to the cooling pipe 107 to reduce thermal resistance.

[0034] The cooling pipe 107 is a serpentine pipe or a plurality of parallel straight pipes, and the serpentine pipe is one or more.

[0035] The channel is semicircular, so as figure 2 As shown, the two opposite sides of adjacent battery modules share the cooling tube 107, ...

Embodiment 2

[0040] like Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, the grooves on the outer wall of the heat conduction housing are parallel double serpentine pipe grooves, and the cooling pipes used are parallel double serpentine pipe grooves. Tube.

Embodiment 3

[0042] like Image 6 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, the grooves on the outer wall of the heat conduction housing are three parallel serpentine pipe grooves, and the cooling pipes used are three parallel snakes. shaped tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com