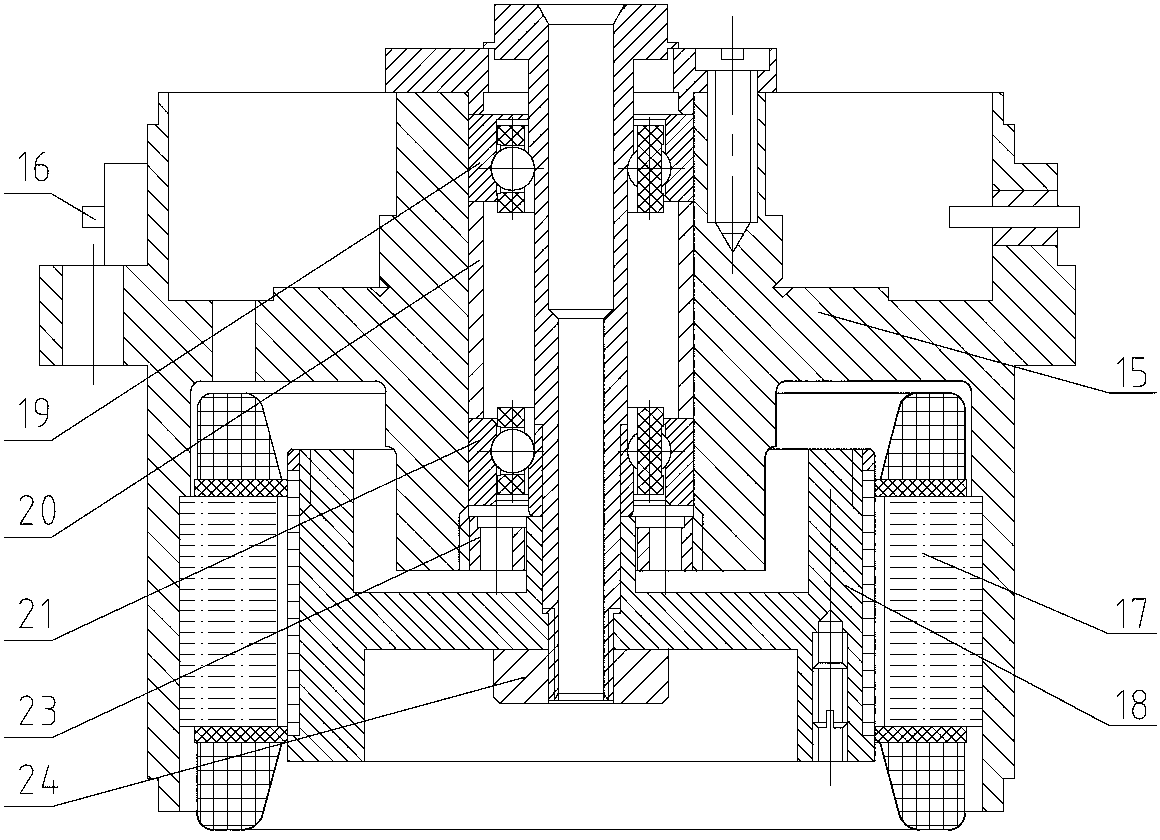

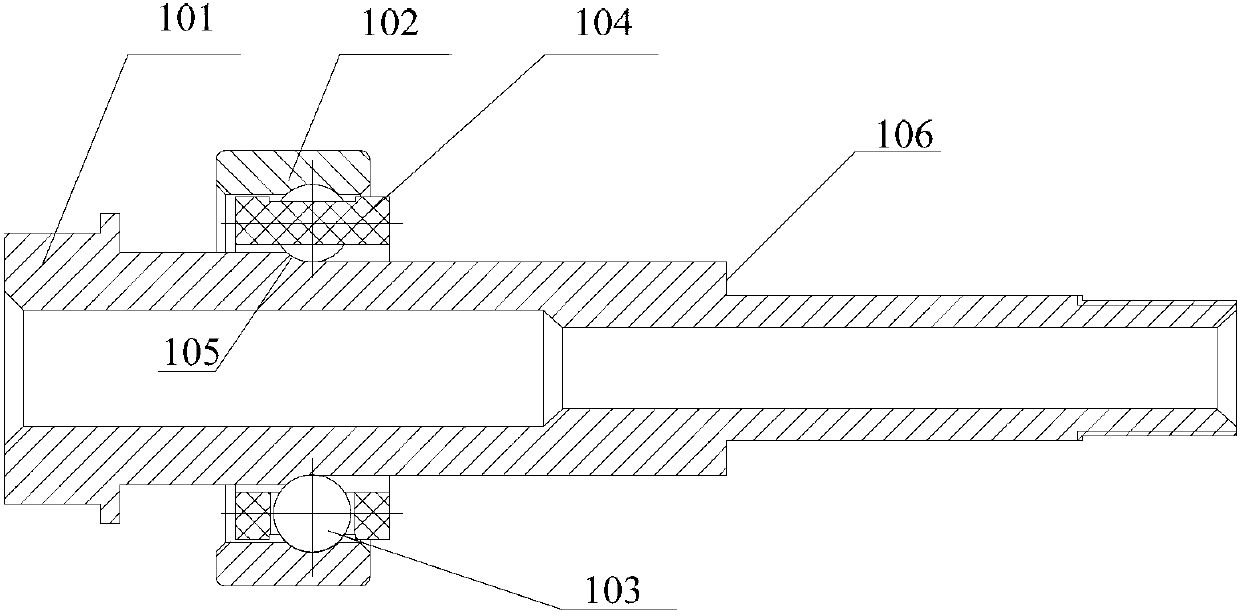

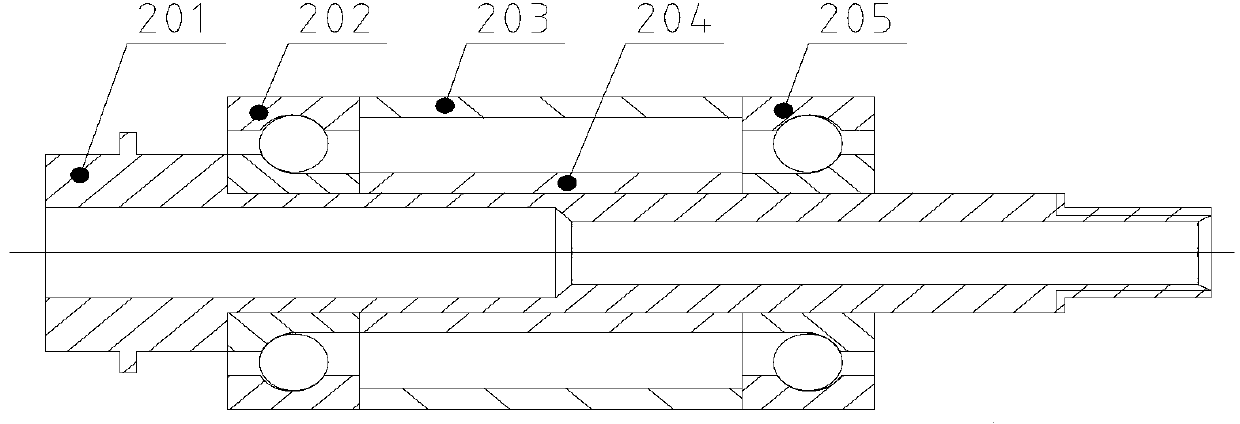

Single shaft coupling bearing unit motor and flexible gyroscope formed by same

A flexible gyroscope and coupling bearing technology, which is applied in the field of flexible gyroscopes, can solve the problems of poor rotation stability of the drive shaft, high vibration and noise of the gyroscope motor, and low mechanical environment resistance, so as to optimize the structure and reduce the electromagnetic Interference moment, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] The expression of the drift error of the flexible dynamic gyroscope is shown in formula (1):

[0029] ω=M / H…………………………………(1)

[0030] In formula (1): ω—gyroscope drift error;

[0031] M—disturbance torque acting on the gyroscope;

[0032] H—Gyroscope angular momentum.

[0033] The expression of the angular momentum H of the gyroscope is shown in formula (2):

[0034] H=C×N……………………………………(2)

[0035] In formula (2): C—gyroscope moment of inertia;

[0036] N—gyroscope rotor rotation speed.

[0037] Therefore to improve the accuracy of the gyroscope and reduce the drift error ω of the gyroscope, it can be carried out from two aspects, one is to reduce the disturbance moment M, and the other is to improve the angular momentum H of the gyroscope. The miniaturized high-precision flexible gyroscope of the present invention adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com