Optical glass

A technology of optical glass and optical components, applied in the directions of optics, optical components, optical surface grinders, etc., can solve the problems of glass stability decline, devitrification, reduction, etc., and achieve the effect of excellent glass stability and high refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

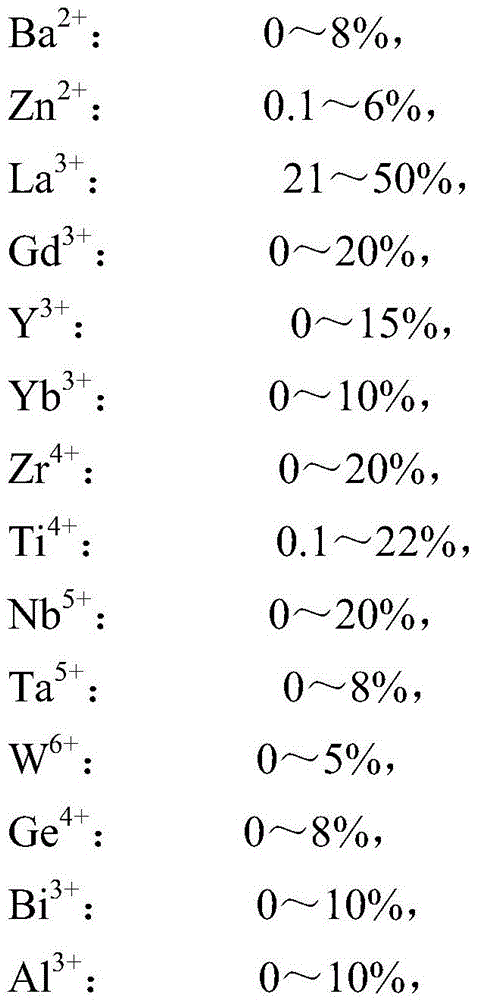

Method used

Image

Examples

Embodiment 1)

[0168] First, in order to obtain oxide glasses Nos. 1 to 36 having the compositions shown in Table 1-1 to Table 1-4 (indicated by cation %), nitrates, sulfates, hydroxides, oxides, etc. were used as raw materials. material, boric acid, etc., weigh each raw material powder, and mix them well to form a blended raw material. Put the blended raw material into a platinum crucible, heat, melt, clarify, and stir at 1400°C to become a uniform melt. Glass. The molten glass was poured into a preheated mold, rapidly cooled, kept at a temperature near the glass transition temperature for two hours, and then gradually cooled to obtain optical glasses of oxide glass Nos. 1 to 36. Precipitation of crystals was not recognized in any of the glasses.

[0169] In addition, the anion components of oxide glasses No. 1 to 36 are all O 2- . In addition, Table 2-1 to Table 2-3 are compositions represented by mass % of oxide glass Nos. 1 to 36, and Table 3-1 to Table 3-3 are compositions represente...

Embodiment 2)

[0206] Next, press-molding glass gobs made of the respective optical glasses of Example 1 were produced as follows.

[0207] First, in order to obtain each of the above-mentioned glasses, glass raw materials are prepared, put into a platinum crucible, and heated, melted, clarified, and stirred to obtain a uniform molten glass. Next, the molten glass flows out from the outflow duct at a constant flow rate, and is cast into a mold arranged horizontally below the outflow duct to form a glass plate having a constant thickness. The formed glass plate is continuously pulled out horizontally from the opening provided on the side of the mold, transported by a belt conveyor to an annealing furnace, and slowly cooled.

[0208] The slowly cooled glass plate is cut or broken to produce glass sheets, and these glass sheets are tumbled to form glass blocks for press molding.

[0209]In addition, a cylindrical mold is arranged below the outflow duct, and molten glass is poured into the mold...

Embodiment 3)

[0211] Same as embodiment 2, the molten glass flows out from the outflow pipe, after the lower end of the molten glass flowing out is caught by the forming mold, the forming mold is lowered urgently, the flow of molten glass is cut off by surface tension, and the desired amount of molten glass is obtained on the forming mold piece. Then, the glass is molded into a gob while blowing gas from the molding die to float the glass by applying upward wind pressure, and the gob is taken out from the molding die and annealed. Then, the glass gob was tumble ground to become a glass gob for press molding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com