Method for improving fermentation-production citric acid yield through use of two-stage dissolved oxygen control technology

A stage control, citric acid technology, applied in microorganism-based methods, biochemical equipment and methods, fermentation and other directions, can solve problems such as single control of dissolved oxygen levels, inability to produce citric acid at the growth and metabolism levels of Aspergillus niger, and achieve important industrial The effect of application value, increased yield, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 13

[0036] Example 13L fermenter two-stage dissolved oxygen fermentation

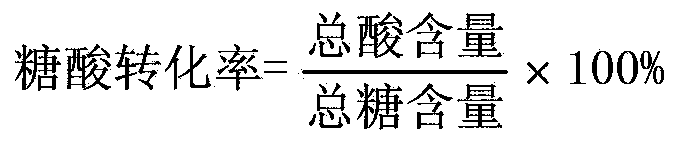

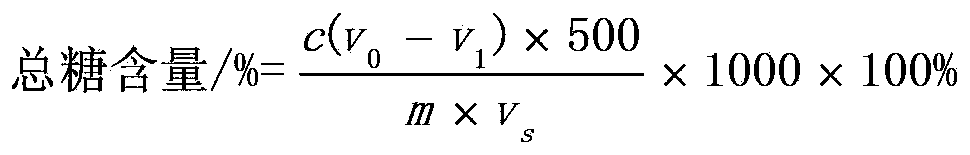

[0037] The 3L fermenter fermentation adopts a two-stage culture method. In the first stage of fermentation (the first 30h), the dissolved oxygen is controlled at 55%, and in the second stage of fermentation (40h), the dissolved oxygen is controlled at 45%. Using this two-stage dissolved oxygen control strategy to ferment and produce citric acid, the sugar-acid conversion rate increased to 93%. All the other fermentation conditions are identical with comparative example 1.

Embodiment 23

[0038] Example 23L fermenter two-stage dissolved oxygen fermentation

[0039] The 3L fermenter fermentation adopts a two-stage culture method, the dissolved oxygen is controlled at 50% in the first stage of fermentation (the first 32h), and the dissolved oxygen is controlled at 40% in the second stage of fermentation (40h). Using this two-stage dissolved oxygen control strategy to ferment and produce citric acid, the sugar-acid conversion rate increased to 95%. All the other fermentation conditions are identical with comparative example 1.

Embodiment 33

[0040] Example 33L fermenter two-stage dissolved oxygen fermentation

[0041] The 3L fermenter adopts a two-stage culture method. In the first stage of fermentation (the first 28h), the dissolved oxygen is controlled at 45%, and in the second stage of fermentation (50h), the dissolved oxygen is controlled at 35%. Using this two-stage dissolved oxygen control strategy to ferment and produce citric acid, the sugar-acid conversion rate increased to 90%. All the other fermentation conditions are identical with comparative example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com