Steel rolling heating furnace

A heating furnace and heating section technology, applied in the field of steel rolling heating furnace, can solve the problems of waste, collapse of retaining walls, waste of funds, etc., and achieve the effects of good cooling effect, saving investment and avoiding collapse of retaining walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

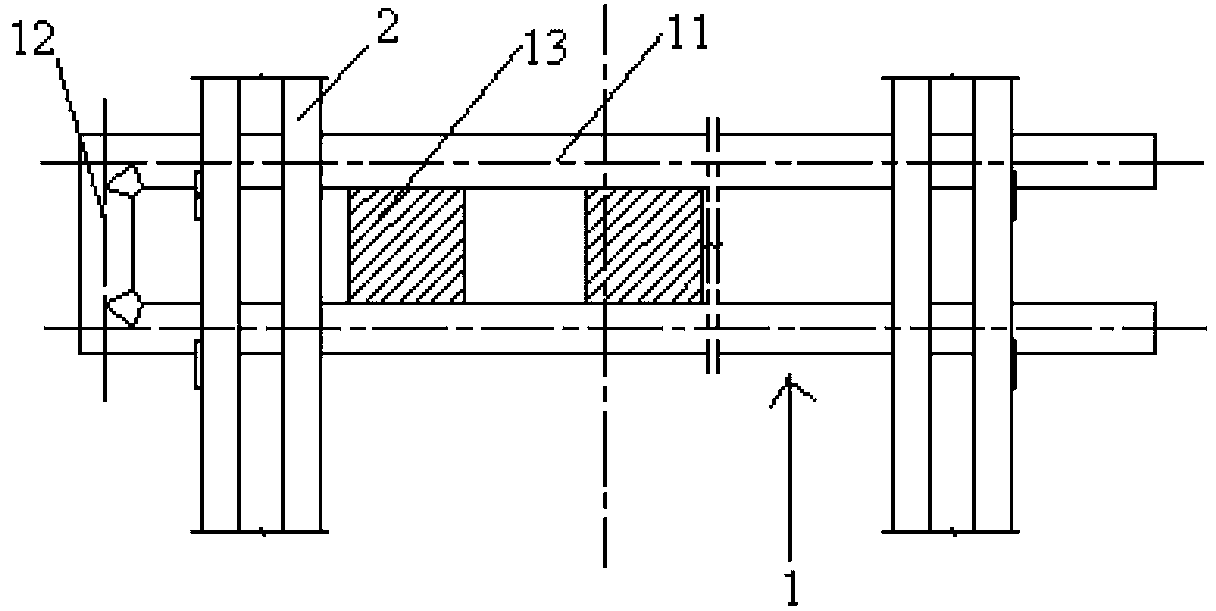

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] see figure 1 In the steel rolling heating furnace of the present invention, the steel tube of the steel rolling heating furnace adopts vaporization cooling, and its furnace includes a preheating section, a heating section and a soaking section arranged in sequence, and a retaining wall is arranged between the heating section and the soaking section. There is a metal pipe 1 inside the wall, one end of the metal pipe 1 is connected with the down pipe of the steam drum, and the other end is connected with the up pipe of the steam drum, and the water separated from the steam-water mixture in the steam drum enters the metal pipe from the down pipe of the steam drum, After absorbing the heat of the retaining wall in the metal pipe, the steam-water mixture is formed and enters the steam drum from the riser. The cooling of the metal pipes in the retaining wall betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com