Integral load-bearing heat-insulating wall plate and production and construction technology thereof

An integrated technology for thermal insulation wall panels, which is applied to buildings, building components, building structures, etc., can solve the problems of poor building seismic capacity, large thermal bridge area, and difficult operation, and saves the need for wall construction and overall structure. The effect of strong sex and reducing casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

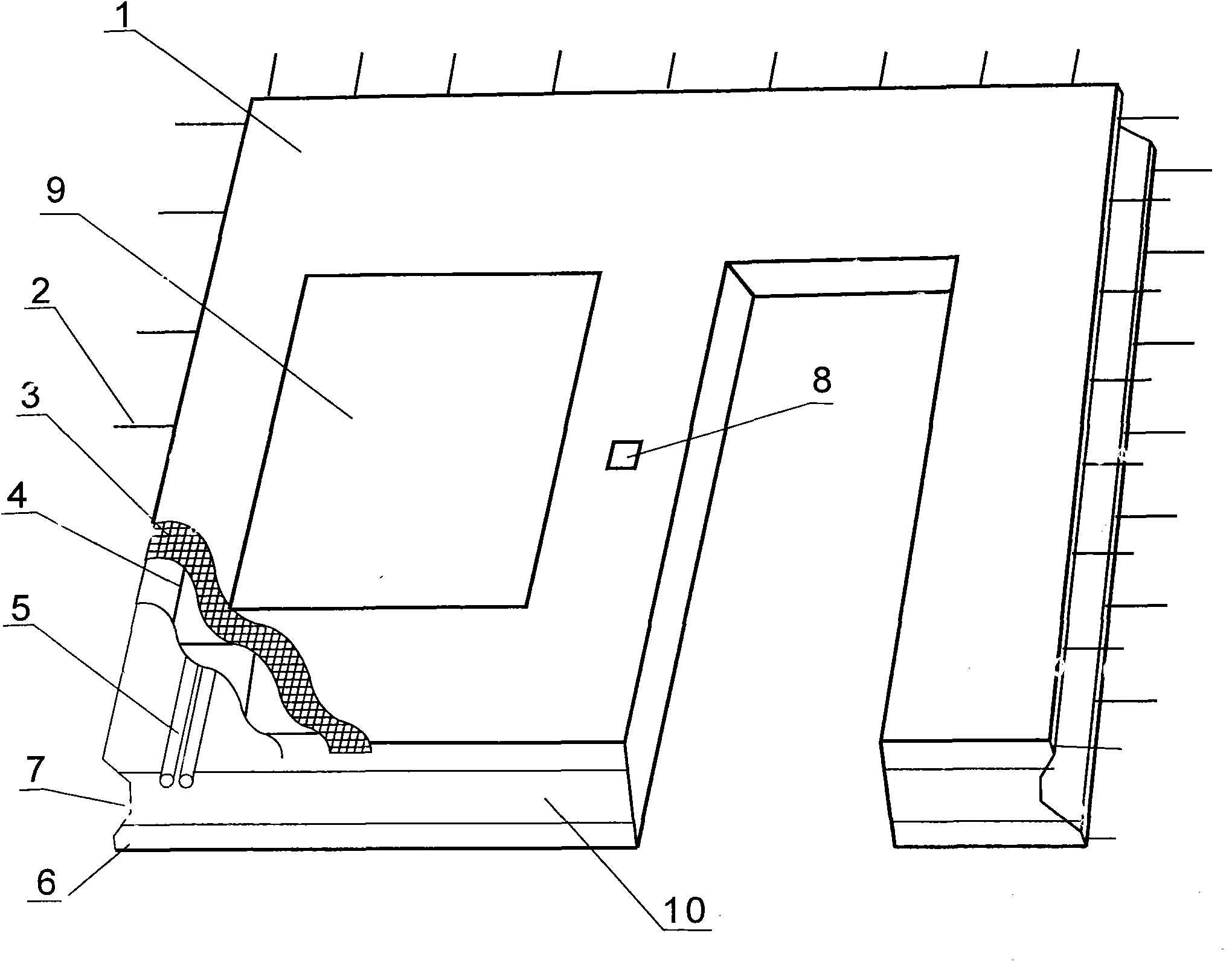

[0023] Make a piece of high 3 meters, long 3.75 meters, a whole load-bearing wall with a thickness of 0.2 meters, weld the steel grid frame (4), leave the door window (9), fix the water, electricity and gas pipelines (5), and wipe the trigger on the Lay the bottom concrete (6) on the ground, and spread the glass fiber mesh (3) at the same time, place the reinforced grid (4) on the bottom concrete (6), and vibrate the mesh under the reinforced grid (4) on the concrete ( In 6), remove excess concrete according to the size, support the surrounding door and window formwork, put in foam cement (10), lower than the steel grid frame (4), and block the water, electricity, and gas pipeline outlets with sponges ( 8), spread the upper layer of concrete (6) and fiberglass mesh (3) with a spreader trigger, remove the formwork after initial setting, maintain, and the overall load-bearing exterior wall panel (1) is finished.

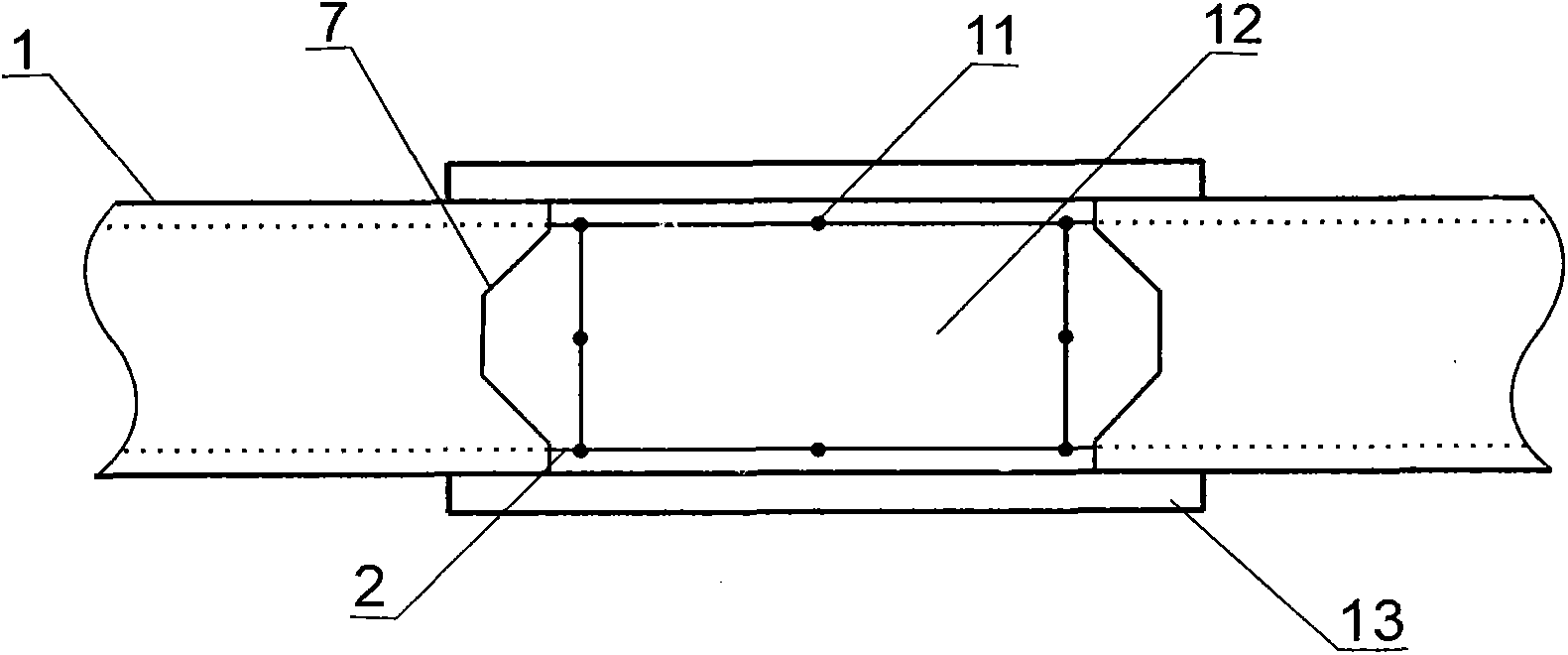

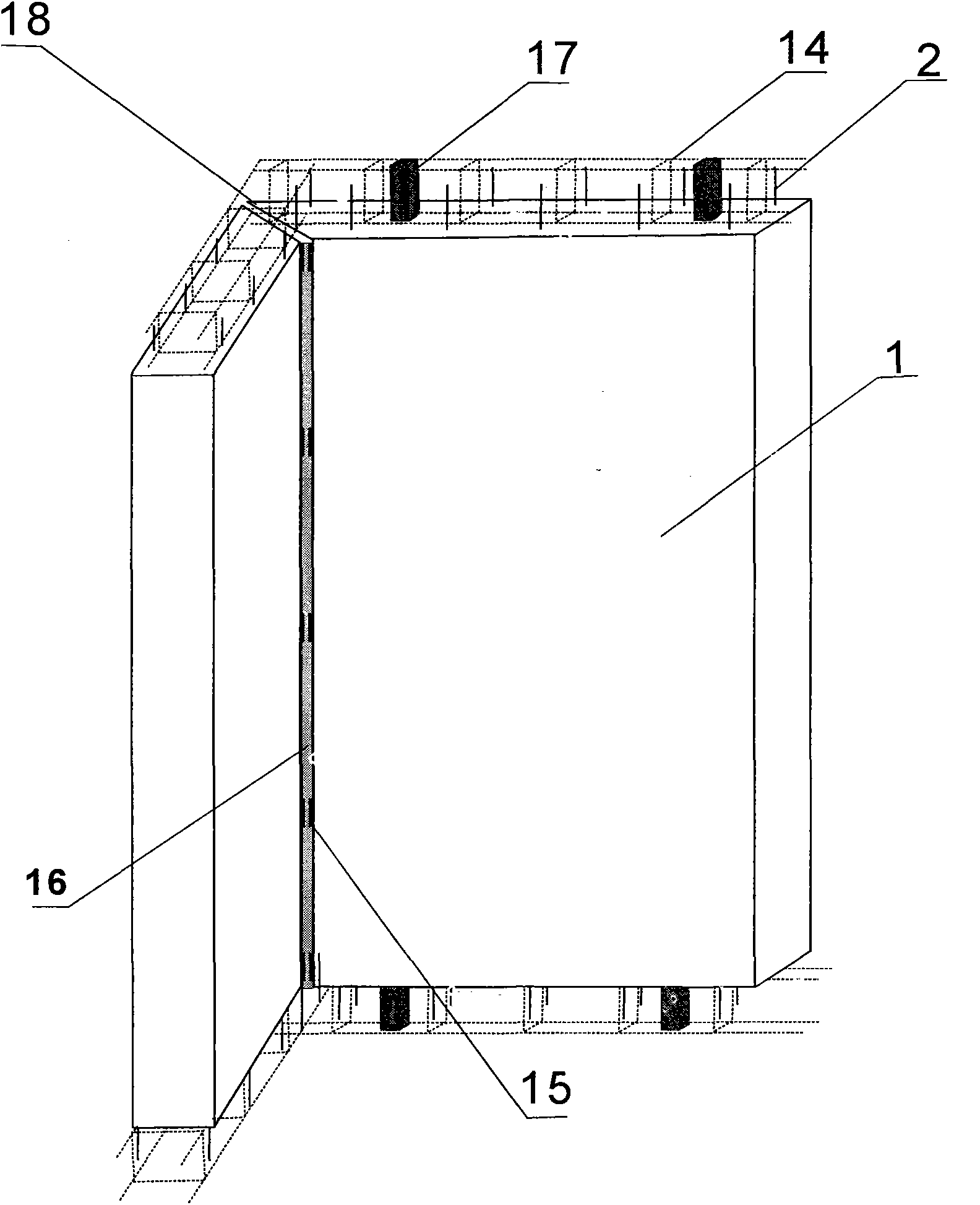

[0024] In the building construction, the wall panel frame connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com