Optimized design method of reducing sonic system sound insulator of acoustic logging-while-drilling drill collar

A design method and optimized technology, applied in surveying, earthmoving, wellbore/well components, etc., can solve the problems of high cost, unfavorable promotion and use of drilling sonic technology, high R&D and processing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

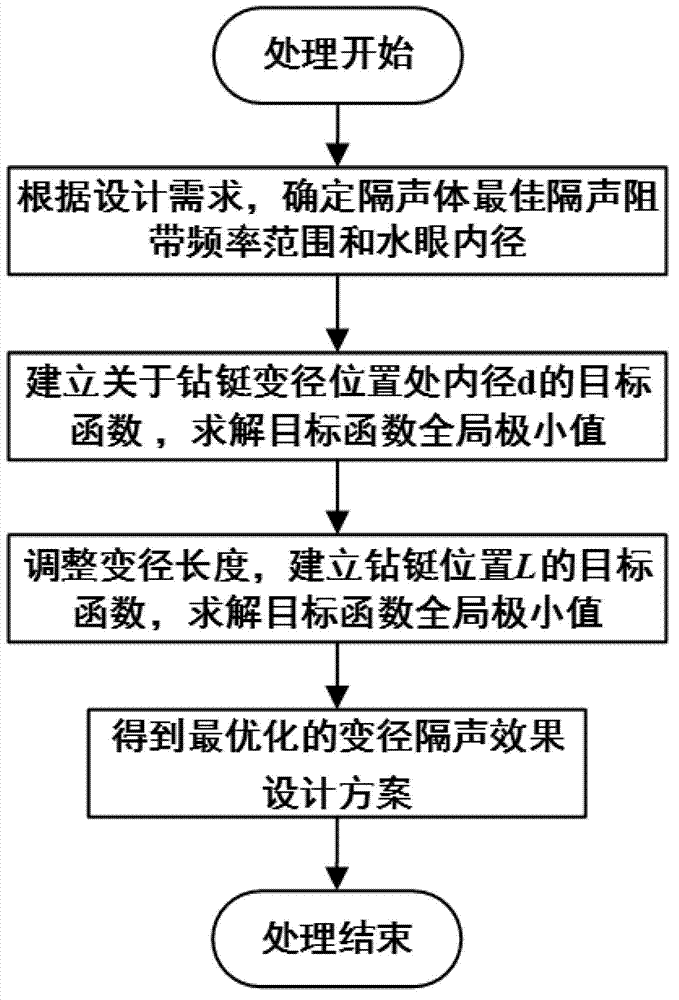

[0064] The optimization design method for the sound insulation of the variable diameter acoustic system of the drill collar with a variable diameter while drilling sonic logging, such as figure 1 As shown, including the following steps:

[0065] Step 1. According to the design requirements, determine the best sound insulation stopband frequency range and the inner diameter of the water eye

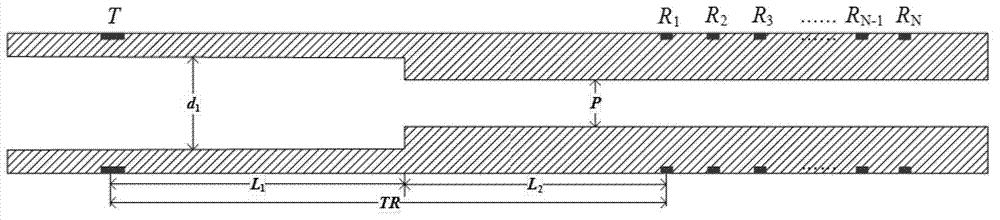

[0066] Figure 2a Shown are the transmitting sound source transducer T and the receiving transducer R 1 , R 2 , R 3 ,.....R N-1 , R N Schematic diagram of the acoustic system of a change in diameter. The inner diameters of the drill collars from the transmitting sound source transducer T to the receiving transducer are d 1 And P, starting from the sound source transducer T, the reduced diameter lengths are respectively L 1 And L 2 , In the figure, T is the transmitting sound source transducer, the receiving transducer array is N, respectively R 1 , R 2 , R 3 ,.....R N-1 , R N .

[0067] 1. Accord...

Embodiment 2

[0080] The optimization design method for the sound insulation of the secondary variable diameter acoustic logging while drilling drill collar variable diameter acoustic system, such as figure 1 As shown, including the following steps:

[0081] Step 1. Determine the best sound insulation stop band frequency range and the inner diameter of the water eye according to the design requirements.

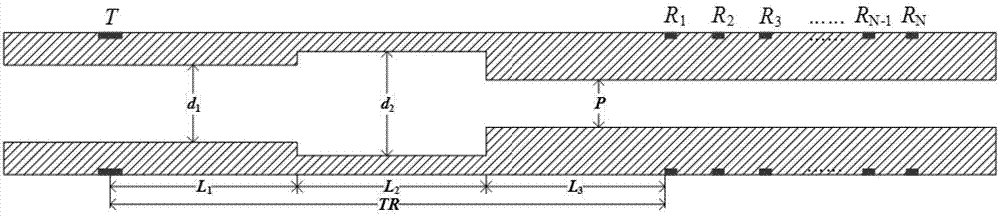

[0082] Figure 2b Shown is a schematic diagram of the acoustic system of the secondary diameter reduction between the transmitting sound source transducer T and the receiving transducer. The inner diameters of the drill collars from the transmitting sound source transducer T to the receiving transducer array are d respectively 1 , D 2 And P, starting from the sound source transducer T, the reduced diameter lengths are respectively L 1 , L 2 And L 3 , In the figure, T is the transmitting sound source transducer, the receiving transducer array is N, respectively R 1 , R 2 , R 3 ,.....R N-1 , R N . ...

Embodiment 3

[0096] The optimization design method for the sound insulation of the three-time variable diameter acoustic logging while drilling drill collar variable diameter acoustic system, such as figure 1 As shown, including the following steps:

[0097] Step 1. According to the design requirements, determine the best sound insulation stopband frequency range, drill collar wall thickness and inner diameter of the water eye

[0098] Figure 2c Shown is a schematic diagram of the acoustic system of a diameter reduction between the transmitting sound source transducer T and the receiving transducer. The inner diameters of the drill collars from the transmitting sound source transducer T to the receiving transducer are d respectively 1 , D 3 , D 2 And P, starting from the sound source transducer T, the reduced diameter lengths are respectively L 1 , L 2 , L 3 And L 4 , In the figure, T is the transmitting sound source transducer, the receiving transducer array is N, respectively R 1 , R 2 , R 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com