Apparatus capable of carrying out on-line detection on glove integrity in isolator system

An integrity and isolator technology, which is applied in the direction of measuring the acceleration and deceleration rate of the fluid and using the liquid/vacuum degree for liquid tightness measurement. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

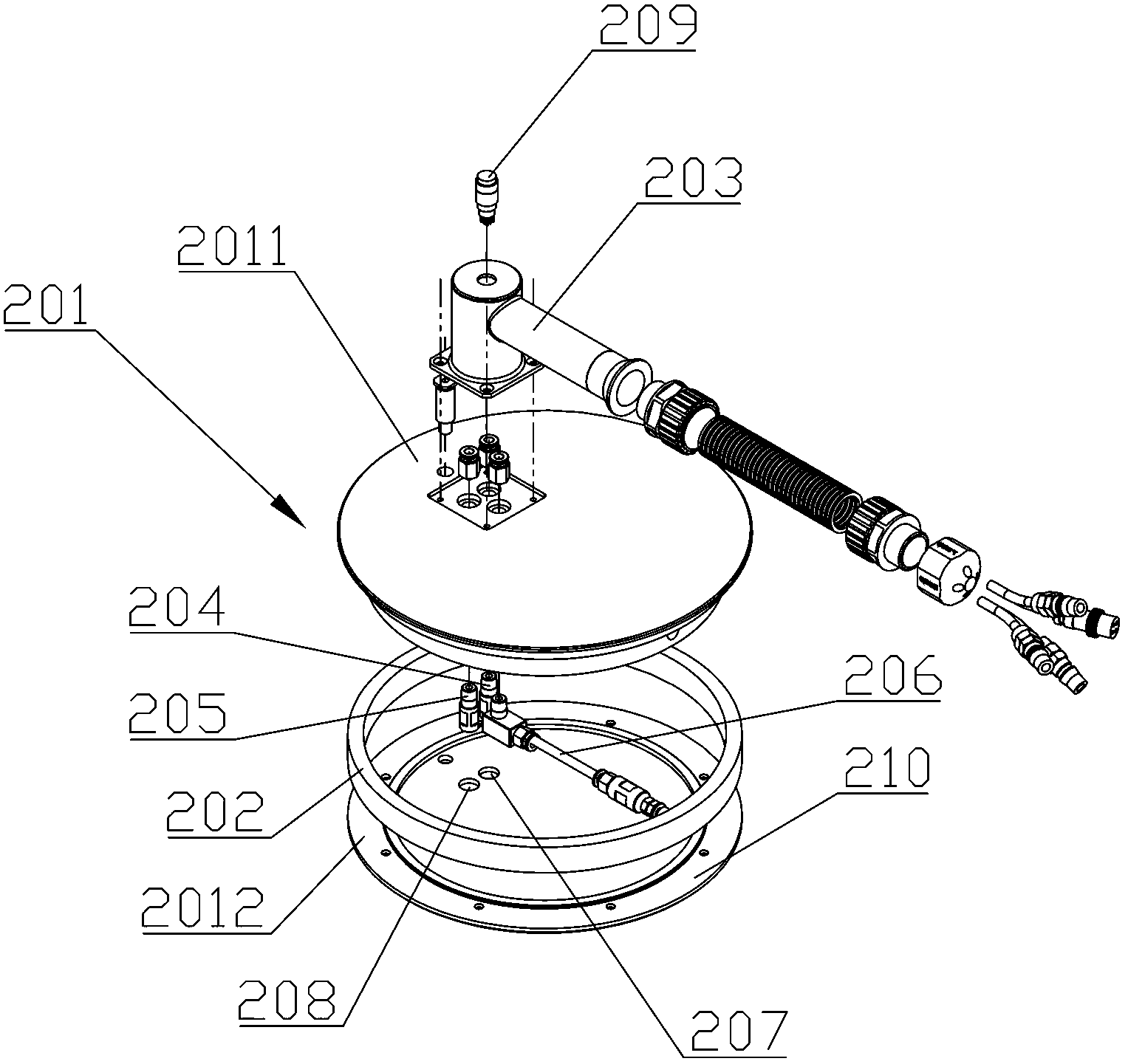

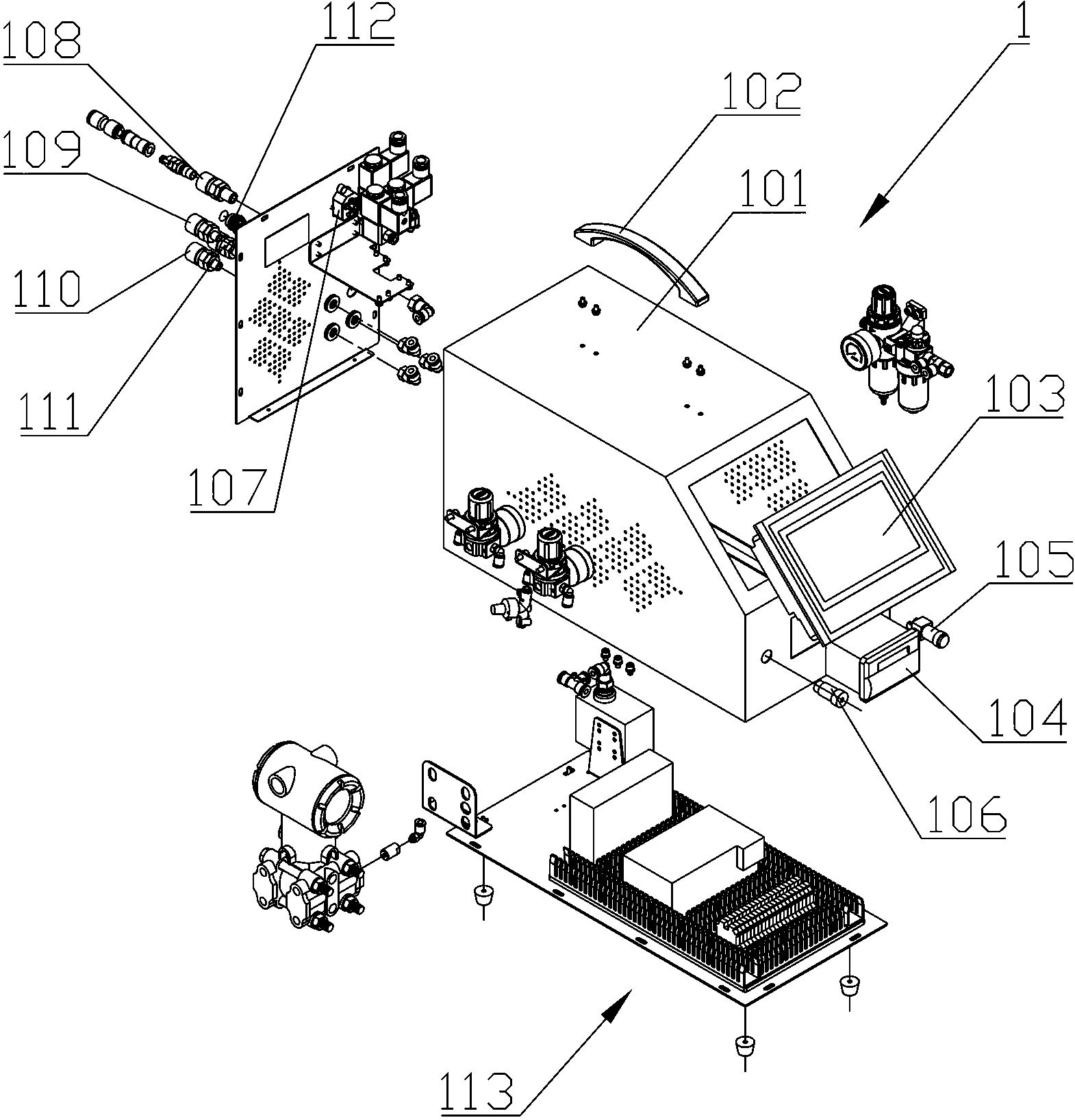

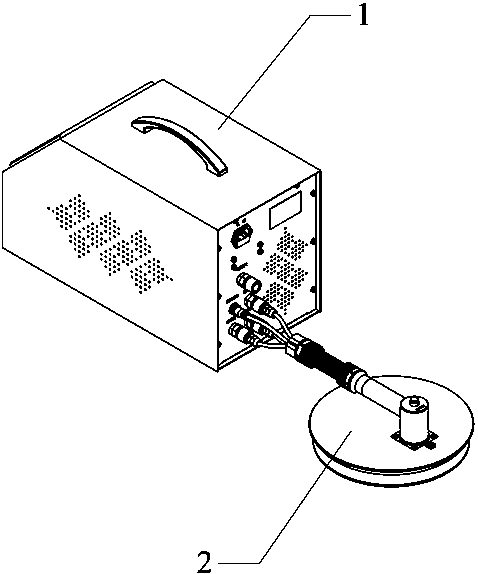

[0026] Devices for on-line detection of glove integrity in isolator systems, such as Figure 1-3 As shown, it consists of a main chassis 1 and a sealing cover assembly 2.

[0027] Sealing cover assembly 2 such as figure 1 As shown, it includes a hollow sealing cover 201 and a hollow square sealing ring 202. The sealing cover 201 is composed of a first sealing cover 2011 and a second sealing cover 2012 stacked up and down. The first sealing cover 2011 and the second sealing cover The plates 2012 are fixedly connected so that the inside of the sealing cover 201 is hollow and airtight. The sealing ring 202 is sleeved around the side wall of the sealing cover 201 , and the first sealing cover 2011 is provided with a hollow L-shaped handle 203 , the shorter arm of the L-shaped handle 203 is fixedly connected with the first sealing cover 201 .

[0028] The sealing cover plate assembly 2 also includes a cuff inflation tube 204, a cuff pressure detection tube 205 and a cover plate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com