Remote Monitoring System of Oilfield Wax Removal Operation Equipment Based on Internet of Things

A technology of remote monitoring system and operation equipment, applied in the direction of electrical program control, comprehensive factory control, etc., can solve problems such as pumping unit failure, equipment accident, affecting normal production, etc., to improve work efficiency, reduce management costs, and enhance practicality. Value and Realistic Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

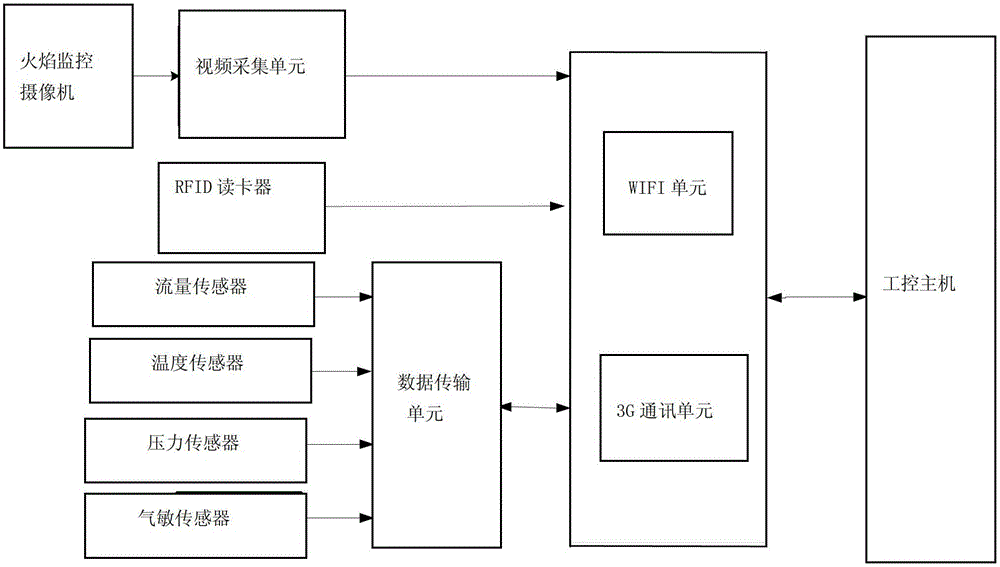

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. like figure 1 As shown, the present invention includes: a flame monitoring camera, a video acquisition unit, an RFID card reader, a flow sensor, a temperature sensor, a pressure sensor, a gas sensor, a data transmission unit [DTU (DataTransferunit)], a network transmission unit, an industrial control host, The network transmission unit includes a WIFI unit and a 3G communication unit.

[0035] The flame monitoring camera, video acquisition unit, network transmission unit and industrial control host are connected in sequence, the RFID card reader is connected to the network transmission unit, and the flow sensor, temperature sensor, pressure sensor, and gas sensor are respectively connected to the data transmission unit connected; the data transmission unit is connected to the network transmission unit.

[0036] The present invention is mainly used for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com