Method for preparing bazhen granule by low-temperature continuous extraction combined with membrane separation technology

A low-temperature continuous extraction, Bazhen granule technology, applied in the directions of medical preparations, drug combinations, and pharmaceutical formulations containing active ingredients, can solve the problems of high reflux extraction temperature, increased energy consumption, unqualified properties, etc. The effect of extracting the extract is too large, the degree of automation is high, and the effective components are retained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

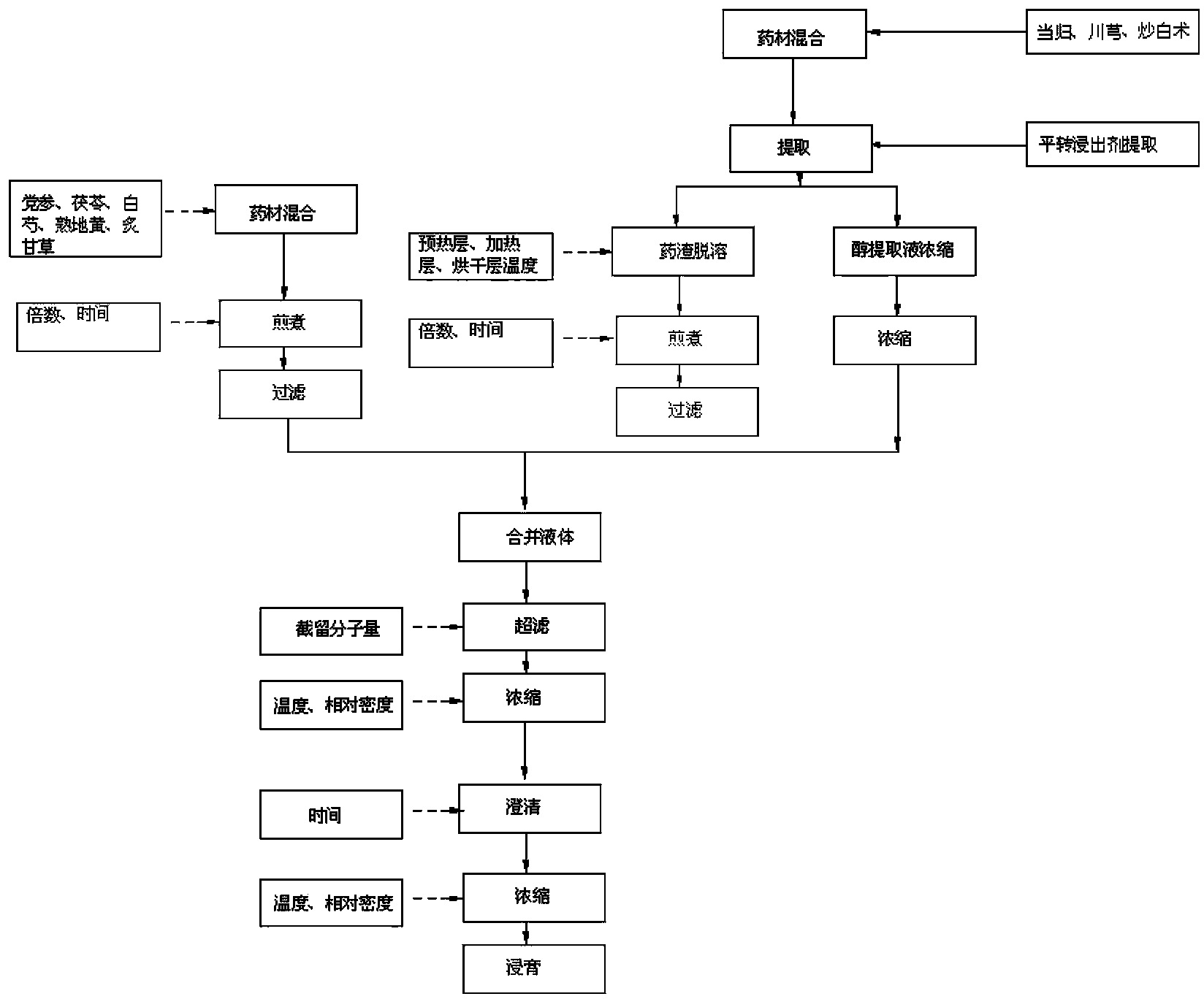

Method used

Image

Examples

Embodiment 1

[0022] Codonopsis, Angelica, Rhizoma Chuanxiong, Rehmannia glutinosa, Atractylodes macrocephala, Radix Glycyrrhizae, Radix Paeoniae Alba, and Poria cocos were collected and processed according to Chinese Pharmacopoeia 2010 Edition 1 and Zhejiang Province Traditional Chinese Medicine Processing Standards (2005 Edition) to make Chinese herbal pieces.

[0023] Dangshen decoction pieces: Take Codonopsis medicinal materials, remove impurities, wash, moisten thoroughly, cut into thick slices, and dry.

[0024] Angelica Herbal Pieces: Take Angelica medicinal materials, remove impurities, wash, moisten thoroughly, cut into thin slices, and dry in the sun or at low temperature.

[0025] Chuanxiong decoction pieces: Take Chuanxiong medicinal materials, remove impurities, separate the size, soak slightly, wash, moisten thoroughly, cut into thin slices, and dry.

[0026] Rehmannia glutinosa decoction pieces: Take the rehmannia root, remove impurities, wash, moisten, cut into thick slices,...

Embodiment 2

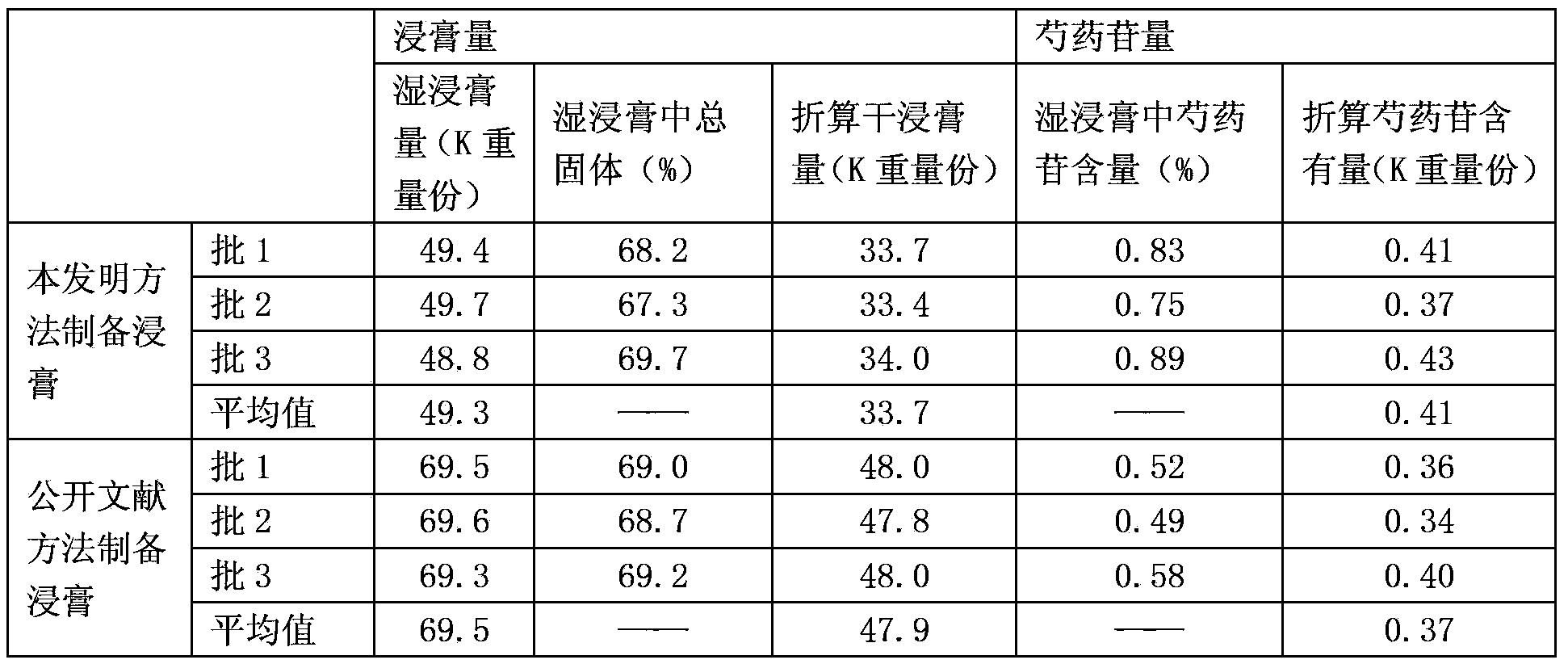

[0032] Weigh the processed Chinese herbal pieces in Example 1, 48K parts by weight of Codonopsis pilosula, 48K parts by weight of Atractylodes macrocephala, 48K parts by weight of Poria cocos, 24K parts by weight of Radix Glycyrrhizae, 72K parts by weight of Angelica sinensis, 48K parts by weight of fried Radix Paeoniae Alba, 36K parts by weight of Rhizoma Chuanxiong , Rehmannia glutinosa 72K parts by weight, set aside.

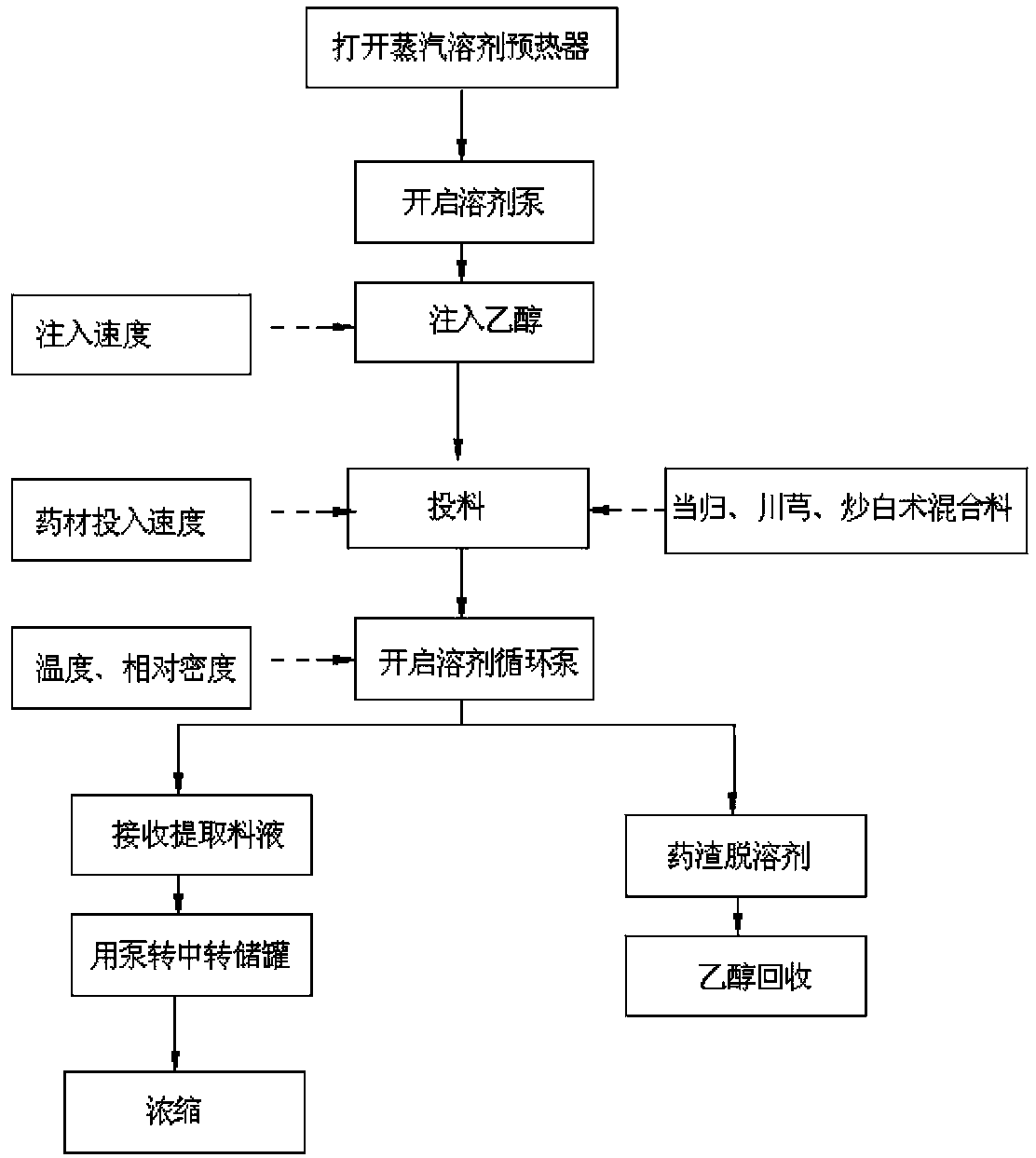

[0033] Mix the weighed angelica, chuanxiong, and fried Atractylodes macrocephala, first turn on the steam solvent preheater to start heating, turn on the solvent pump, and extract 75% ethanol at a solvent injection speed of 2000L / h (the temperature of the extraction solvent is controlled at 60-65°C between) until the solvent fills the pan extractor to the last grid sight glass; then start the feeding system, continuously feed in medicinal materials at a speed of 200kg / h, and turn on the solvent circulation pump one by one; start to receive the extraction solut...

Embodiment 3

[0038] Get a portion of the extract prepared in Example 2, add excipients as sucrose and an appropriate amount of dextrin, granulate, dry, and granulate to make 200K parts by weight of granules, and pack them into 8 parts by weight / bag. A sugar-containing Bazhen granule product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com