Gum collector for eucommia ulmoides samara husks

A technology of eucommia samara and gluing machine, which is applied in the field of eucommia samara shell processing equipment, can solve the problems of ineffectiveness, troublesome operation, high cost, etc., and achieve the effects of reliable operation, simple and applicable structure, and high work efficiency

Inactive Publication Date: 2013-10-23

JISHOU UNIVERSITY

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, to extract high-purity Eucommia gum from Eucommia ulmoides samara shell, it is generally necessary to remove impurities such as cellulose and lignin in the shell first, and most of the impurities such as lignin and cellulose in the shell are removed by biological and chemical methods. The main method is to use alkaline method or fermentation method to remove impurities such as cellulose and lignin in Eucommia samara shells, but biological and chemical methods are often cumbersome to operate, with high costs, and a lot of waste liquid will be generated, which will pollute the environment and fail to reach ideal effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

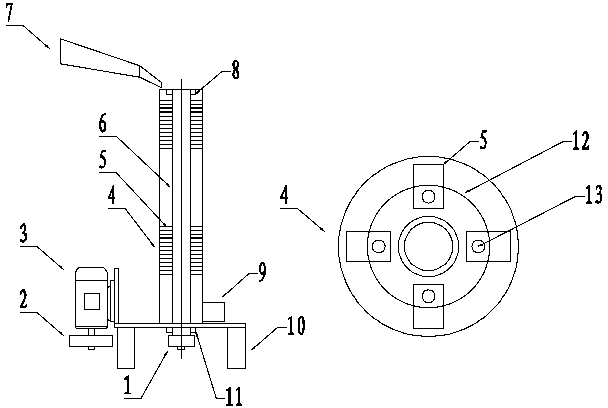

The invention discloses a gum collector for eucommia ulmoides samara husks. The gum collector comprises a spindle pulley, a motor pulley, a motor, an outer cylinder, gum collecting plates, a spindle, a feed hopper, an upper bearing pedestal, a discharge port, machine legs, a lower bearing pedestal, rotating disks and pins. The outer cylinder is a long steel pipe. The upper bearing pedestal and the lower bearing pedestal are disposed at two ends of the outer cylinder respectively to provide rotor supporting. The spindle that is long is provided with a plurality of the evenly spaced rotating disks. Each of the rotating disks is provided with four uniform circular holes where the pins can be inserted. Linings are disposed among the gum collecting plates, and the linings and the gum collecting plates are integrated by threading the pins to form four groups of rotors. The gum collector has characteristics of simple and applicable structure, reliable operation, high work efficiency, environmental protection, low cost and strong feasibility, and can efficiently collect eucommia ulmoides gum in the eucommia ulmoides samara husks.

Description

technical field [0001] The invention relates to an eucommia samara shell processing equipment, in particular to a mechanical device for removing impurities such as cellulose and lignin from the eucommia samara shell to enrich the eucommia gum. Background technique [0002] The whole body of Eucommia ulmoides is a treasure, the kernel is rich in linolenic acid, and the shell of the samara contains 15-30% of Eucommia gum, which is a new functional material with a wide range of uses; how to further enrich Eucommia The glue thread in the samara shell is of great significance for the further development and utilization of eucommia gum resources and the improvement of the economic value of eucommia samara. At present, to extract high-purity Eucommia gum from Eucommia ulmoides samara shell, it is generally necessary to remove impurities such as cellulose and lignin in the shell first, and most of the impurities such as lignin and cellulose in the shell are removed by biological a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08J3/00C08L7/00

Inventor 陈功锡张永康银永忠高莹王时贤杨绍波

Owner JISHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com