Underfill adhesive composition

A technology of underfill and composition, applied in the direction of adhesive, epoxy resin, adhesive type, etc., can solve the problems of production line bottleneck, long curing time, poor fluidity, etc., and achieve fast flow speed, fast curing speed, The effect of increasing toughness and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

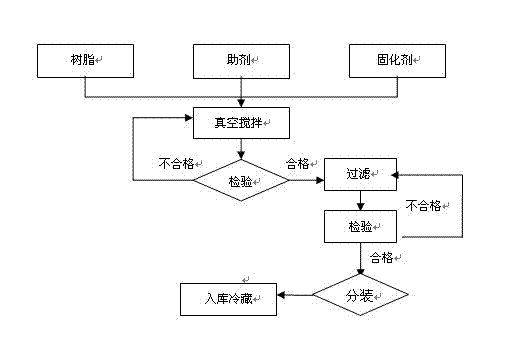

Method used

Image

Examples

Embodiment 1

[0036] The composition is:

[0037] Hydrogenated bisphenol A: 375kg;

[0038] 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexyl carboxylate: 1000kg;

[0039] Polyurethane modified epoxy resin: 12.5kg;

[0040] Nano silicone resin: 15kg;

[0041] Pluracol 1016: 137.5kg;

[0042] Boron trifluoride-monoethylamine complex: 10kg;

[0043] Boron trifluoride-triethanolamine complex: 17.5 kg.

Embodiment 2

[0045] The composition is:

[0046] 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexyl carboxylate: 650kg;

[0047] Bis[7-oxabicyclo(4.1.0)heptane-3-methyl]adipate: 725kg;

[0048] Polyurethane modified epoxy resin: 10.5kg;

[0049] Nano silicone resin: 17kg;

[0050]Multranol 9158: 120kg;

[0051] Boron trifluoride-monoethylamine complex: 12kg;

[0052] Boron trifluoride-piperidine complex: 15.5 kg.

Embodiment 3

[0054] The composition is:

[0055] Hydrogenated bisphenol A: 275kg;

[0056] Bis[7-oxabicyclo(4.1.0)heptane-3-methyl]adipate: 1100kg;

[0057] Polyurethane modified epoxy resin: 10.5kg;

[0058] Nano silicone resin: 17kg;

[0059] Voranol 3010: 120kg;

[0060] Boron trifluoride-monoethylamine complex: 12kg;

[0061] Boron trifluoride-piperidine complex: 15.5 kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com